13 Cr oil well-pipe test material object preparation method

An oil well pipe and physical technology, which is applied in the field of 13Cr oil well pipe test physical preparation, to achieve the effect of shortening the test period, improving technical ability and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] There are two kinds of materials to be welded in the present invention, one is 13Cr stainless steel oil well pipe, and the other is a 35CrMo or similar material chuck used in the test for high pressure sealing test, the chuck also acts as a plug. Specific technical features include:

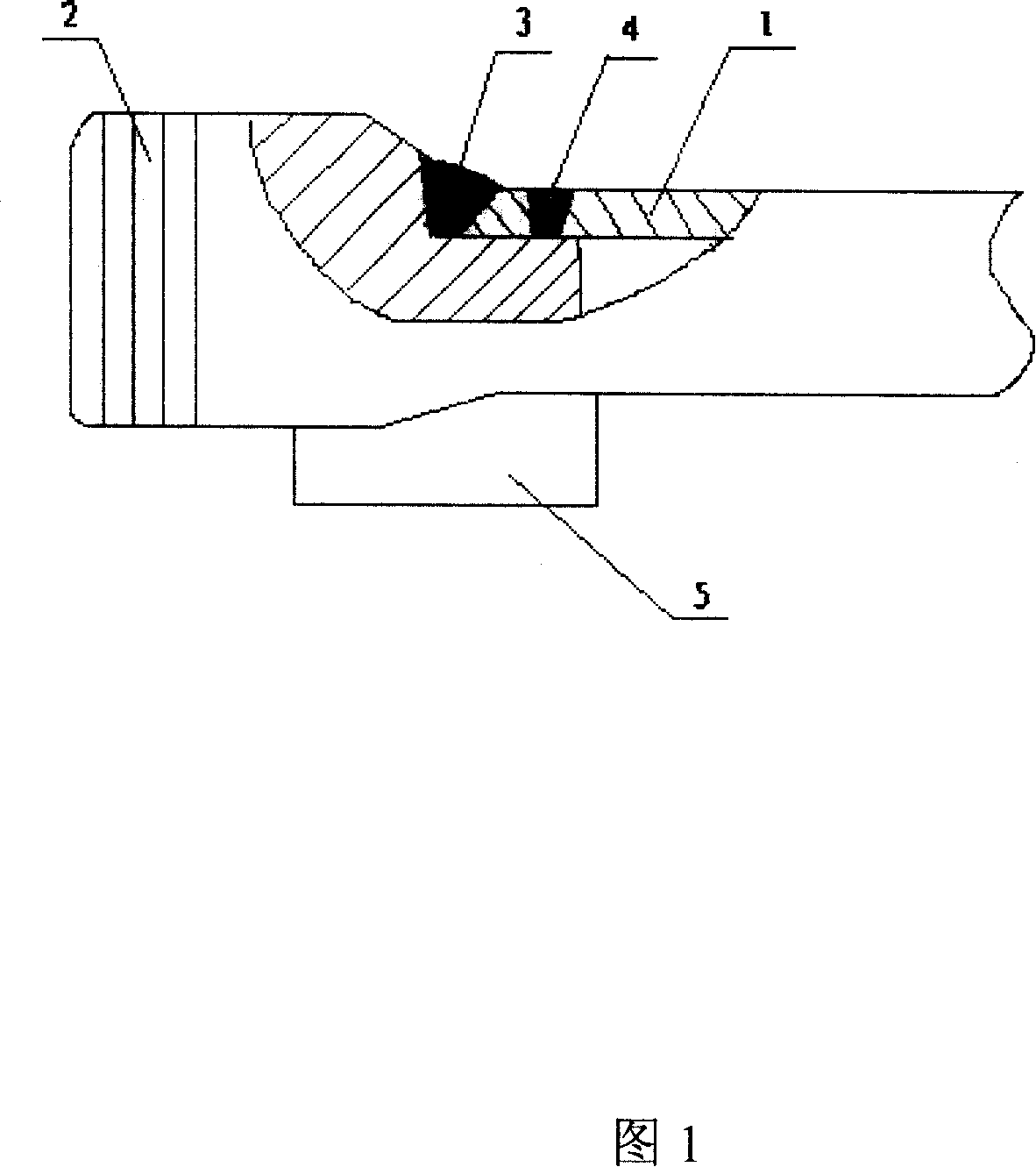

[0026] In the structural form shown in Figure 1, first, the two ends of the oil well pipe (1) to be tested are processed into welding grooves, and a number of plug welding holes uniformly distributed along the circumference are processed according to the distance of 100mm from the end face of the welding groove; One end of the test chuck (2) is processed into a groove and the test pipe welding groove is welded to form the main load-bearing weld (3), and the other end is threaded externally or internally to connect with the test equipment; the root of the plug welded seam (4) It is welded with the chuck, and the side is connected with the test tube; or / and a circle of reinforcing ribs (5) i...

Embodiment 2

[0038]For the specification of 88.90×6.45mm and the model of KO-13Cr-110 FOX oil pipe (common 13Cr stainless steel) produced by a Japanese company, the chuck welding was carried out by using the process of Example 1, and five kinds of parameters were stretched or stretched under internal pressure. Compression test: (1) The tensile load is 130,000kg, the internal pressure is 0, and the duration is 5 minutes, without any leakage and cracking; (2) The tensile load is 89,400kg, the internal pressure is 86.2MPa, and the duration is 5 minutes , without any leakage or cracking; (3) The compressive load is 50,800kg, the internal pressure is 109MPa, and the duration is 5 minutes, without any leakage or cracking; (4) The compressive load is 90,000kg, the internal pressure is 82.7MPa, and the continuous (5) The compressive load is 130,000kg, the internal pressure is 0, and the load lasts for 5 minutes. During the loading process, the oil pipe is unstable and deformed, but the welded join...

Embodiment 3

[0040] For the bushing (super 13Cr stainless steel) produced by a Japanese company with a specification of 137.70×9.17mm and a model of KO-HP1-13Cr110 FOX, the chuck was welded using the process of Example 1, and the internal pressure cycle and thermal cycle tests were carried out. The pressurization medium is dry nitrogen, and the leakage of the sample is detected by using a bubble bottle, and the pressurization rate is <34MPa / Min. A total of two parameters were tested, and the sample numbers were 1Z and 2Z. The 1Z sample was at 177°C, the test pressure was 64.5MPa, the 2Z sample was at room temperature, the test pressure was 87.9MPa, and the test method was cycled for one week according to the prescribed test method, and no leakage occurred.

[0041] After the test, continue to increase the test pressure until the sample fails. The internal pressure of the 1Z sample reached 131.6MPa, and the internal pressure of the 2Z sample reached 131.2 (2Z) MPa. The pipe body exploded,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com