Highly effective double-element nitration reactor

A nitrification reactor and reactor technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc. Volume conversion efficiency, enhanced matrix transfer, and the effect of ensuring reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

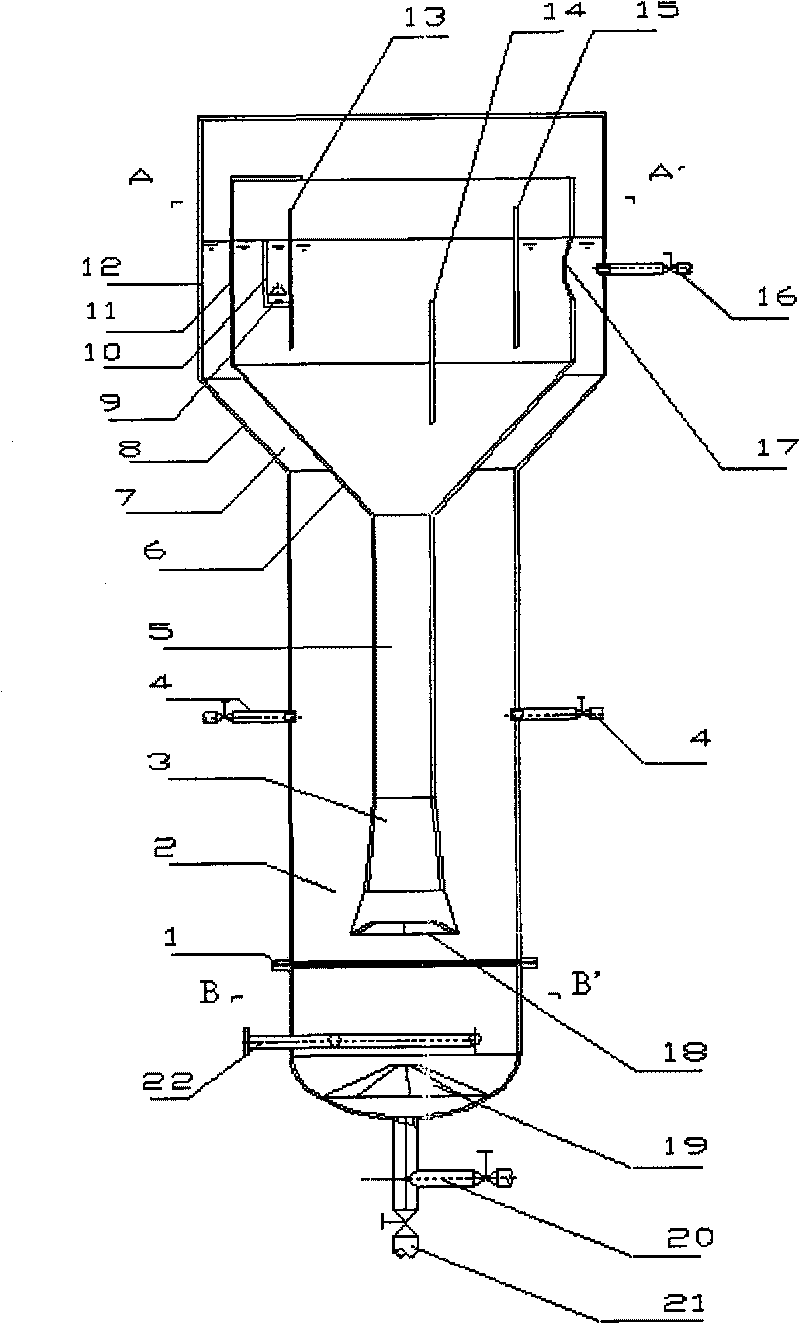

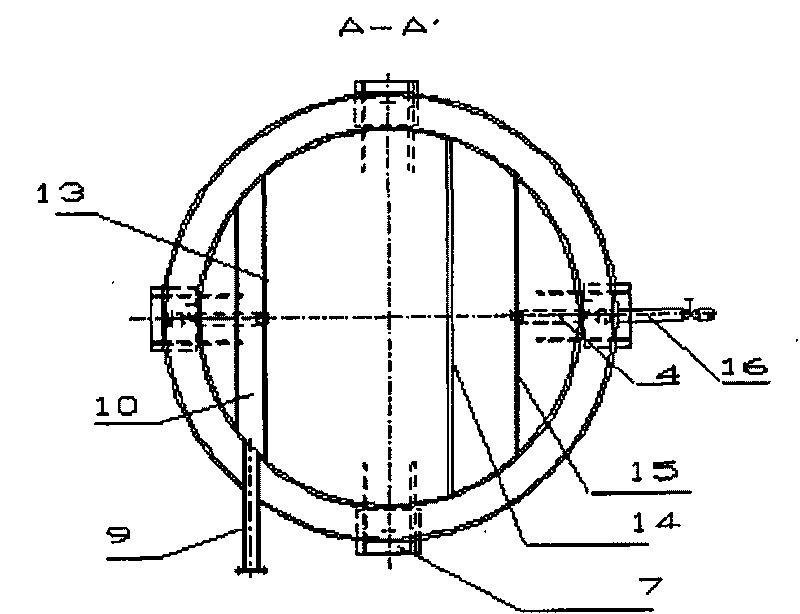

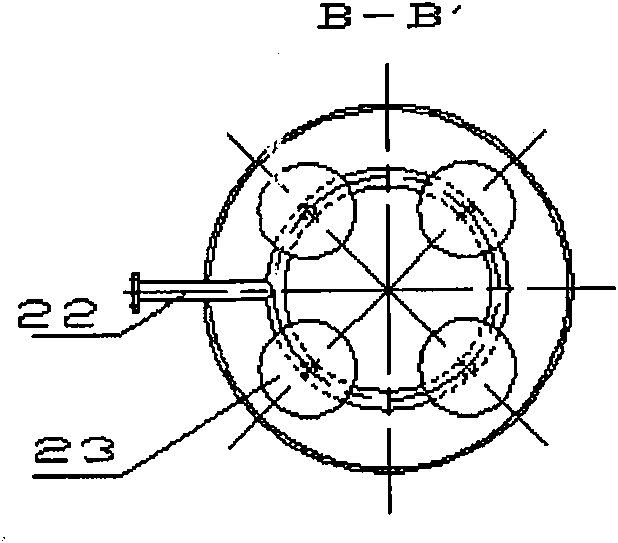

[0013] The high-efficiency binary biological nitrification reactor is composed of two units, the outer unit is the reactor body, and the reactor body is provided with an upflow reaction chamber 2, and the upflow reaction chamber 2 is connected to the outer cylinder 12 through the outer cone cylinder 8. connection, the side wall of the outer cylinder 12 is provided with a slag discharge pipe 16, and the upflow reaction chamber 2 is provided with an aeration pipe 22, a swirl water distributor 19, and a mud discharge pipe 21, and the aeration pipe 22 is provided with an aeration pipe The head 23, the sludge discharge pipe 21 is provided with a water inlet pipe 20, and the side wall of the upflow reaction chamber 2 is provided with a plurality of sampling ports 4. The inner unit is a sludge sedimentation system, and the sludge sedimentation system is provided with a sedimentation chamber 11. The side wall of the chamber 11 is connected with the circulation pipe 5 through the inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com