Method and device for decreasing contamination

A technology of equipment, diagnostic equipment, applied in the field of clean rooms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Example 1: In vitro simulation

[0092] The simulated cough machine system was designed similarly as described by King Am J. Respir. Crit. Care Med. 156(1):173-7 (1997). Construct an air-tight 6.5 liter Plexiglas tank with additional digital pressure measuring instrument and pressure relief valve as the capacitive function of the lungs. The tank is pressurized and a compressed air cylinder with regulator and air filter is connected to the inlet. At the inlet of the tank, an Asco two-way normal closed solenoid valve (8210G94) with sufficient Cv flow coefficient was connected for gas release. Reinforced solenoid valve with typical 120V, 60Hz light switch wire. The outlet port connected to the solenoid valve is a Fleisch no. 4 pneumotachometer, which creates the required Poiseuille flow detection "cough" profile. The outlet of the Fleisch tube was connected to the 1 / 4'' NPT inlet to the model trachea. The Validyne DP45-14 Differential Pressure Transducer measures the p...

Embodiment 2

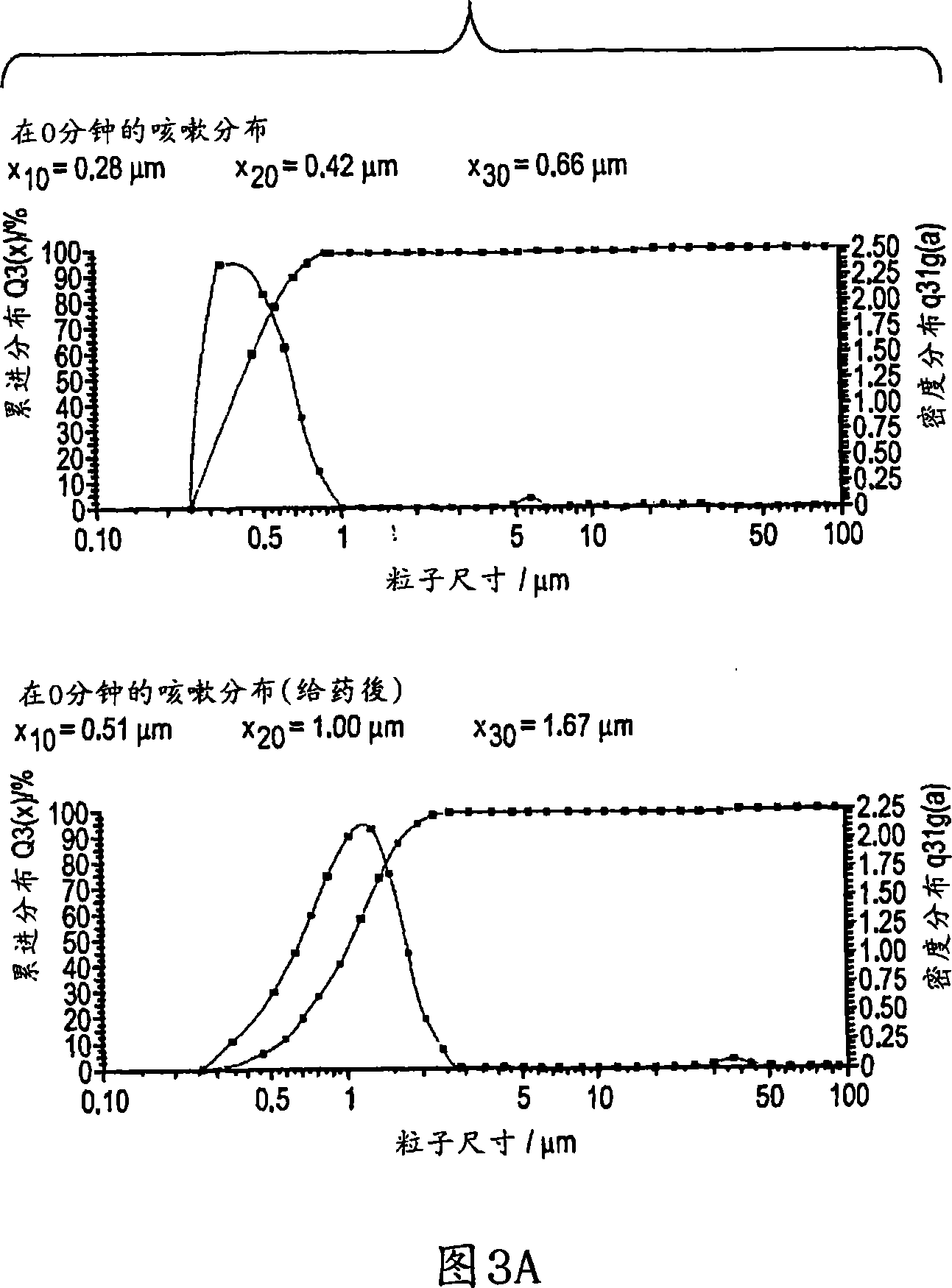

[0095] These in vitro results show that application of saline to the mucus layer resulted in fragmentation with a substantial increase in particle size, possibly due to increased surface tension. As shown by the in vivo results, large size droplets were less able to exit the oral cavity. Therefore, the solution was administered to significantly reduce the amount of exhaled particles. Example 2: Reduction of Exhaled Airborne Particulates in Human Studies

[0096] A proof of concept study of exhaled aerosol particle generation was performed using 12 healthy individuals. The objectives of the study were (1) to determine the properties (size distribution and number) of exhaled bioaerosols; (2) to demonstrate the utility of the device sensitive enough to correctly count exhaled particles; (3) to estimate baseline counts of exhaled particles from healthy lungs; and (4) measuring the effect of two exogenously administered treatment sprays on inhibition of exhaled particle counts. ...

Embodiment 3

[0103] Example 3: Large animal studies

[0104]Seven Holstein steers were anesthetized, intubated and screened, and the baseline particle emission was measured by optical laser counting. Animals were then either untreated (sham) or treated with one of three doses (1.8 minutes, 6.0 minutes or 12 minutes) via a saline aerosolized spray. In the case of sham dosing, animals were treated in the same manner as they were dosed with isotonic saline solution. One animal was dosed daily and by random nebulizer throughout the exposure period (see Table 3 for dosing schedule). Each selected animal received all doses during the study. Exhaled particle counts were monitored for 180 minutes at discrete time points (0, 15, 30, 45, 60, 90, 120) after each dose was administered.

[0105] The exposure matrix for the animals used in this study can be found in Table 3. During the 57-day dosing period, there was an interval of at least 7 days between dosing. During the dosing period, each anim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com