Emergency handling process for sudden burst of raw material alga

An emergency treatment and raw water technology, applied in the direction of adsorption water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as poor emergency algae removal efficiency, poor treatment effect, and aggravated water pollution , to achieve ideal removal effect, low cost of use and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0014] The field experiment was conducted with a water supply of 230,000m 3 / d's Jinan Yuqing water plant.

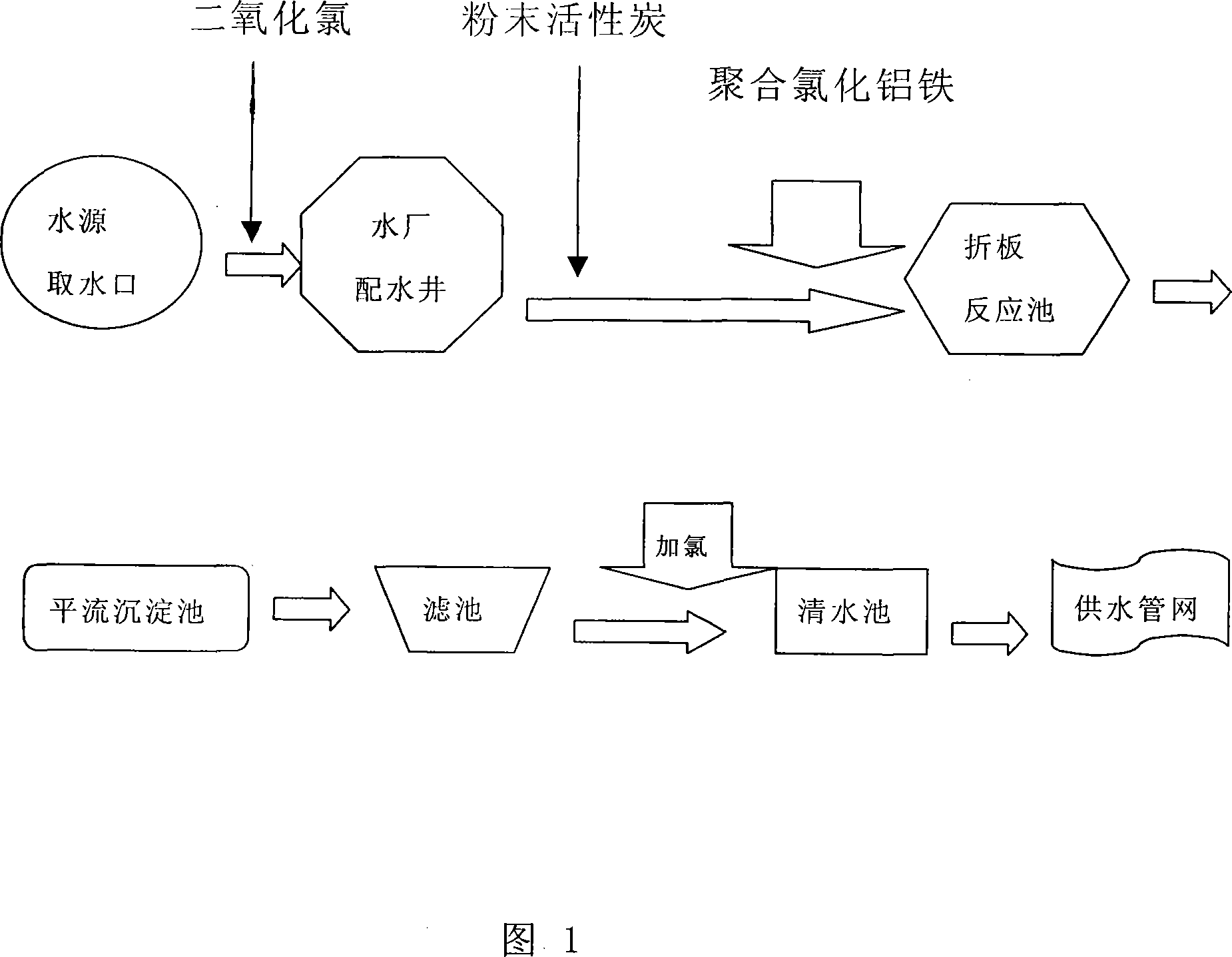

[0015] As shown in Figure 1, the present embodiment adopts the following steps: 1) take water from the water intake of the water source, add chlorine dioxide pre-oxidation: the dosage is 1mg / L, and send it to the distribution well of the water plant; 2) from the distribution well Fetching water, adding powdered activated carbon adsorption dosage is 10mg / L; 3) remixing: adding polyaluminum ferric chloride, dosage is 5.9mg / L, using pipeline mixer to mix; 4) Reaction: ordinary reaction tank ;5) Sedimentation: Advection pool, the length of the pool is 100m, and the residence time is 2.2h; 6) Filtration: Filtration rate is 10m / h, air and water recoil, air impact intensity is 70m 3 / h·m2, the water flushing intensity is 13m 3 / hm 2 ; 7) Disinfection: Chlorine disinfection, the dosage is 3mg / L, input into the clear water pool, and then sent to the water supply pipe network...

specific Embodiment 2

[0016] The field experiment was conducted with a water supply of 230,000m 3 / d's Jinan Yuqing water plant.

[0017] As shown in Figure 1, the present embodiment adopts the following steps: 1) take water from the water intake of the water source, add chlorine dioxide pre-oxidation: the dosage is 2mg / L, and send it to the distribution well of the water plant; 2) from the distribution well Take water, add powdered activated carbon for adsorption, the dosage is 20mg / L; 3) remix: add polyaluminum ferric chloride, the dosage is 5.9mg / L, and mix with pipeline mixer; 4) Reaction: folding plate Reaction pool; 5) Sedimentation: Advection pool, pool length 120m, residence time 2h; 6) Filtration: V-shaped filter, filtration rate 8m / h, air-water recoil, air impact intensity 55m 3 / h·m2, the water flushing intensity is 11m 3 / h·m 2 ; 7) Disinfection: Chlorine disinfection, the dosage is 2.7mg / L, input into the clear water pool, and then sent to the water supply network.

specific Embodiment 3

[0018] The field experiment was carried out in Jinan Yuqing Water Plant with a water supply of 230,000 m3 / d.

[0019] As shown in Figure 1, this specific embodiment adopts the following steps: 1) take water from the water intake of the water source, add chlorine dioxide pre-oxidation: the dosage is 4.5mg / L, and send it to the distribution well of the water plant; Take water from the well, add powdered activated carbon for adsorption, and the dosage is 40mg / L; 3) remix: add polyaluminum ferric chloride, the dosage is 5.9mg / L, and mix with a pipeline mixer; 4) Reaction: folding Plate reaction pool; 5) Sedimentation: advection pool, pool length 120m, residence time 2h; 6) Filtration: V-shaped filter, filtration rate 8m / h, air-water recoil, air impact intensity 55m 3 / h·m2, the water flushing intensity is 11m 3 / h·m 2 ; 7) Disinfection: Chlorine disinfection, the dosage is 3.4mg / L, input into the clean water pool, and then sent to the water supply pipe network.

[0020] The wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com