Method and device for manufacturing optical cable connector metal lock pin

A technology for optical fiber connectors and manufacturing methods, which is applied in the field of manufacturing and installation of metal ferrules for optical fiber connectors, can solve problems such as difficult production, large equipment loss, and inability to weld, and achieves a high degree of automatic control and stable electroforming parameters , the effect of uniform metal layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

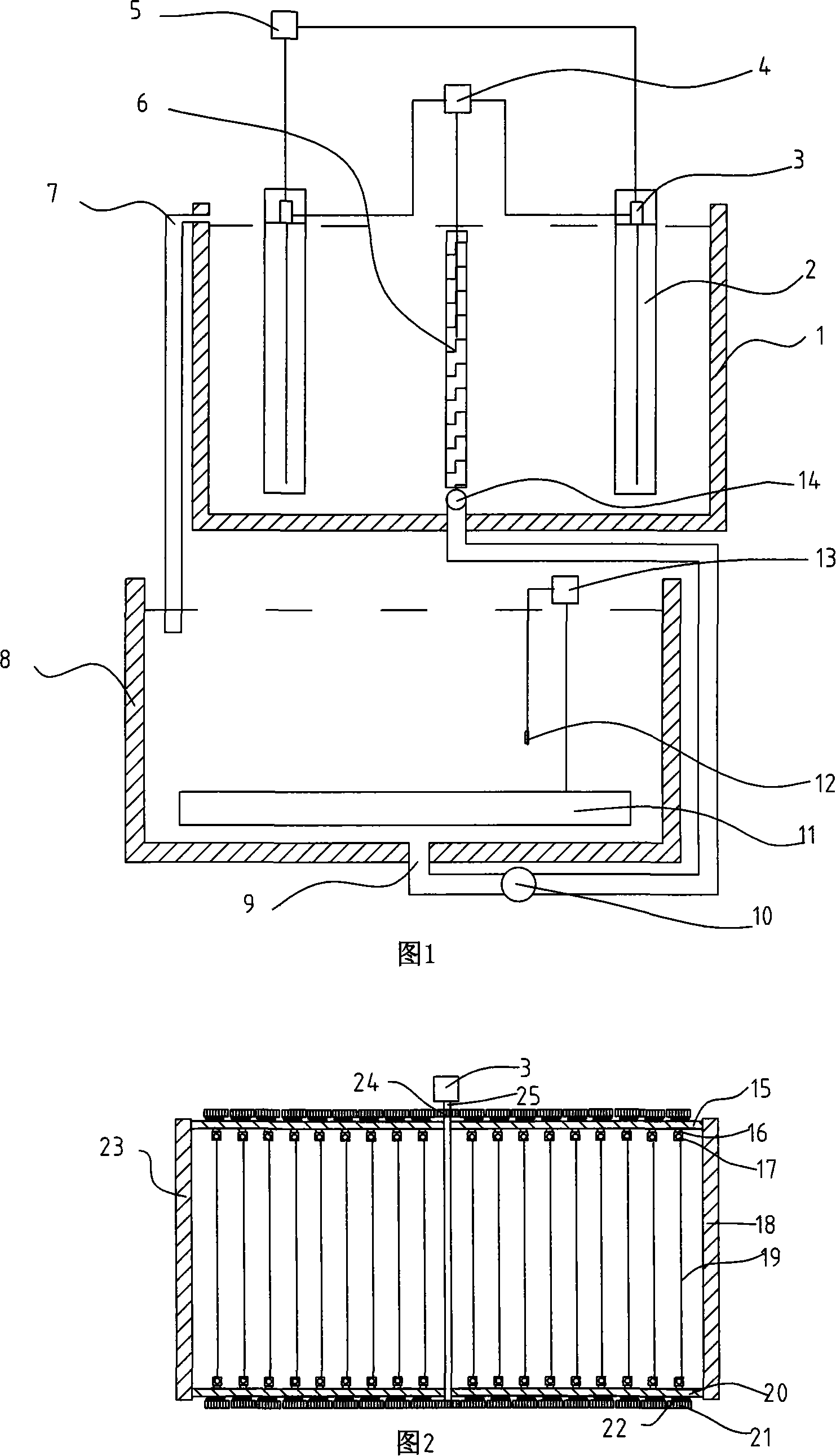

[0022] Referring to Figures 1-2, a method for manufacturing a metal ferrule for an optical fiber connector of the present invention includes the following steps:

[0023] a. install the core wire 19 on the core wire shelf 2;

[0024] b. Degreasing and activating the core wire 19;

[0025] c. Place a titanium metal mesh basket 6 in the middle of the electroforming pool 1, and put metal nickel in the mesh basket; place core wire shelves 2 symmetrically on both sides of the titanium metal mesh basket 6;

[0026] d. The titanium metal mesh basket is connected to the anode of the power supply 4, and the core wire shelves on both sides are respectively connected to the cathode of the power supply 4, forming a single anode and double cathode structure;

[0027] e. Put the electroforming solution in the temperature control tank 8, and control the temperature between 50-60°C;

[0028] f. The electroforming solution in the temperature control tank is automatically pumped into the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com