Method for manufacturing wood grain and marble glass

A technology of marble pattern and manufacturing method, which is applied in the field of wood grain and marble pattern glass manufacturing, can solve the problems of high cost and difficulty in mass production, and achieve the effects of simple production, good water resistance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

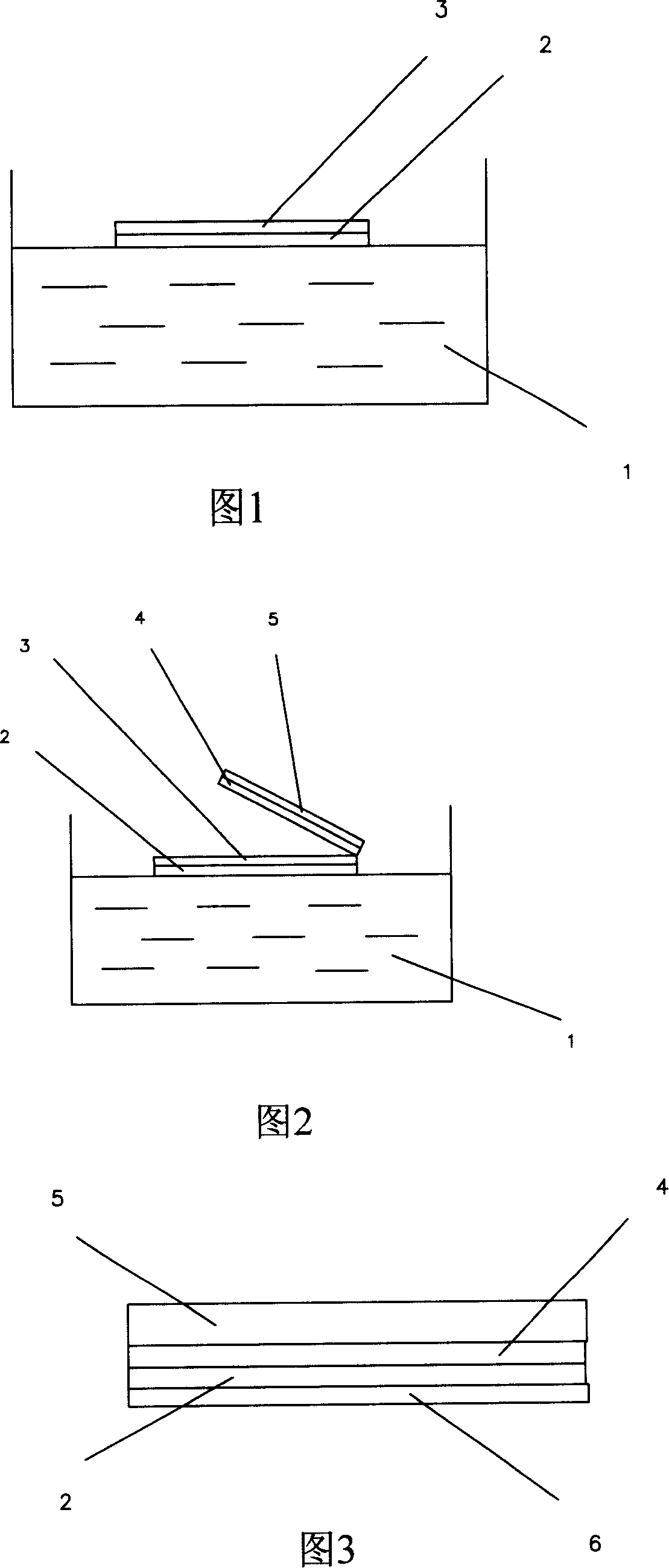

[0040] See Figures 1 and 2:

[0041] The manufacturing method steps of wood grain and marble grain glass of the present invention are as follows:

[0042] The first step, spray primer:

[0043] Spray an appropriate amount of special varnish for transparent glass on the glass, the amount of spraying is 20-100 grams per square meter; after spraying, bake in an oven for 20-50 minutes at a baking temperature of 70-80 degrees Celsius; take out the glass and cool it down to room temperature for use;

[0044] The second step, membrane activation:

[0045] Spread the water-coated transfer film on the water surface of the transfer tank, place the graphic layer upwards, keep the water in the tank clean and basically in a neutral state, and spray evenly on the surface of the graphic with an activator to make the graphic layer Activation, easy to separate from the carrier film. The activator is an organic solvent mainly composed of aromatic hydrocarbons, which can quickly dissolve and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com