A green bamboo-wood composite board and its processing technology

A bamboo-wood composite and composite board technology, which is used in wood processing appliances, sugarcane machining, and the joining of wooden veneers, etc. , Bamboo green surface hardness, flatness, smoothness are not easy to maintain, not conducive to environmental protection and other problems, to achieve the effect of natural rich texture, high smoothness, high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

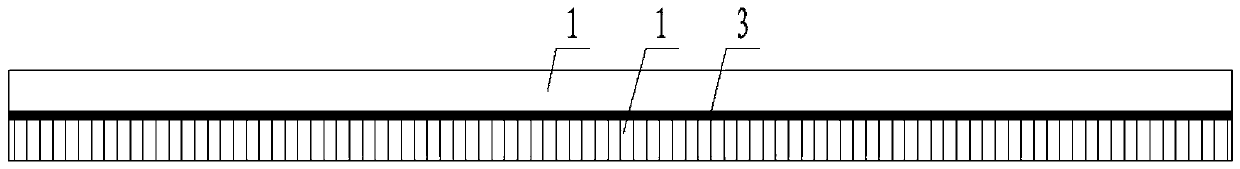

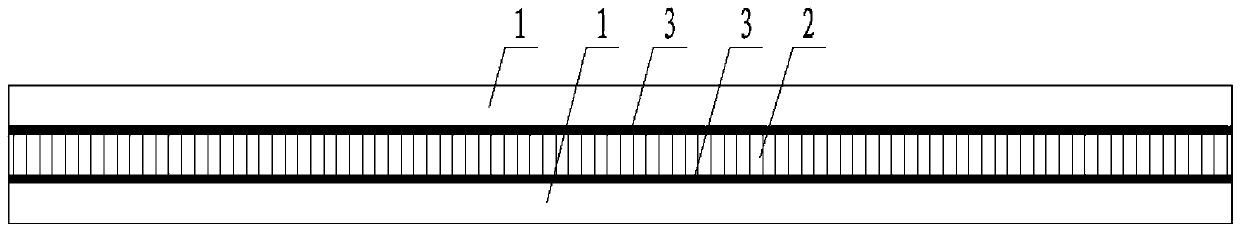

[0046] Such as figure 1 As shown, the present invention discloses a green bamboo composite board, including a single-sided structure and a double-sided structure. A green bamboo board 1 and the joinery wood board 2 therebetween are bonded by glue 3, the outer surface of the green bamboo board 1 is a bamboo green surface, and the inner surface is a bamboo yellow surface.

[0047] Further, the bamboo green surface of the stay-green bamboo board maintains a thin layer of natural bamboo green texture.

[0048] A processing technology of green bamboo-wood composite board, the processing steps are:

[0049] A, choose the high-quality moso bamboo that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com