Bamboo-wood mixed reconstituted timber and its processing method

A processing method and technology of recombined wood, applied to wood processing appliances, other household appliances, household components, etc., can solve the problems of low strength, poor forming texture, and difficult manufacturing, and achieve the effect of high strength and rich texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

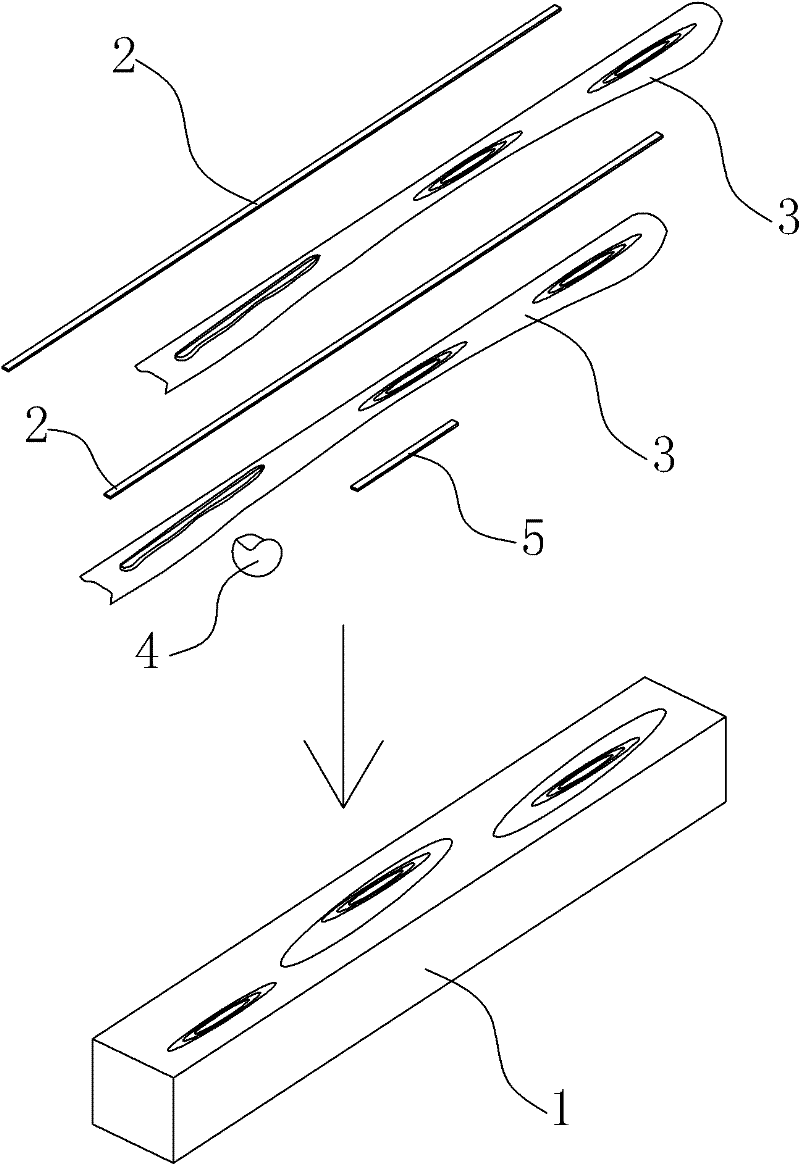

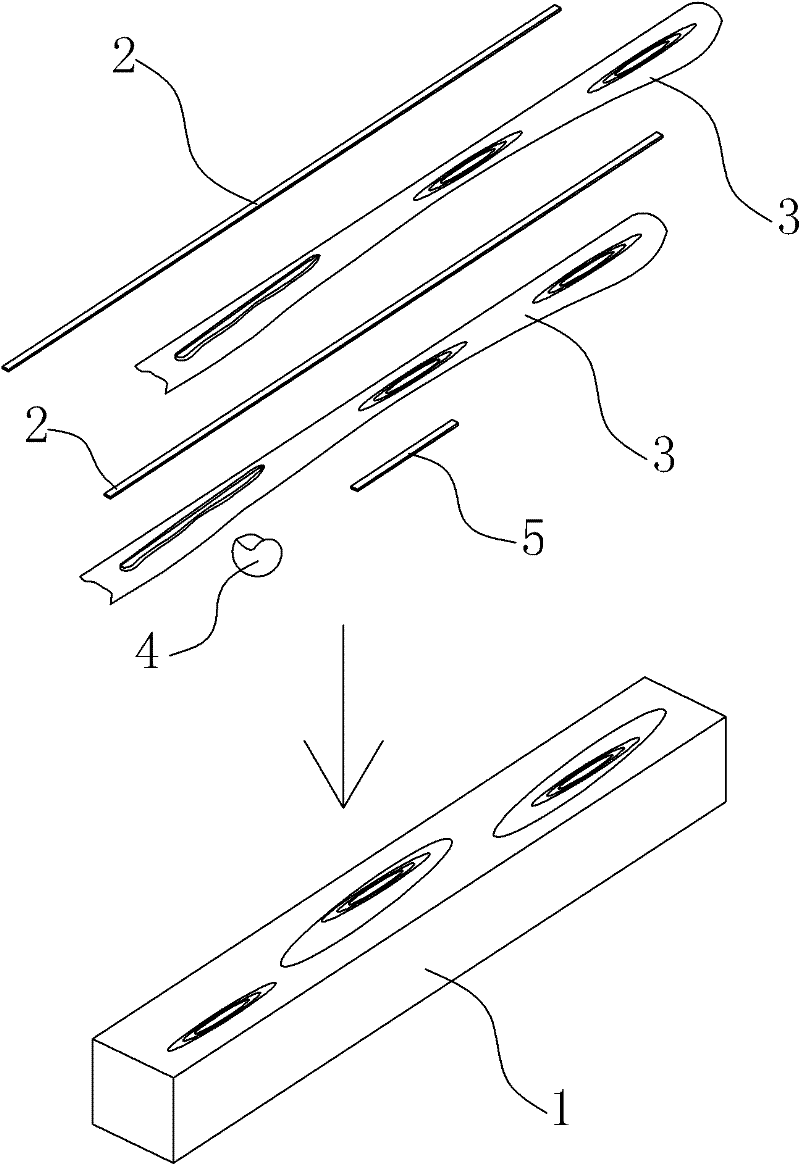

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] like figure 1 As shown, the bamboo-wood mixed recombined wood 1 includes bamboo 2 and wood 3, and the bamboo 2 and wood 3 are equal in length and in the same direction. Silk, the wood 3 is wood bundles and / or single wood chips, and the bamboo 2 and wood 3 are randomly filled with plant accessories such as walnut shells 4 and bamboo powder 5 .

[0025] Embodiment 1 of the processing method of bamboo and wood mixed heavy wood comprises the following steps carried out in sequence:

[0026] a. Bamboo 2 and wood 3 are heated and dried, and the moisture content is controlled at 10%. The bamboo is bamboo bundle monomer and / or conjoined bamboo filaments, and the wood is wood bundle and / or single wood chip;

[0027] b. Soak the dried bamboo and wood in the natural color or the water-soluble phenolic resin glue solution treated by toning for 6 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com