Micro-chamber self-lubricating knife tool and preparation method thereof

A cutting tool and micro-pool technology, applied in lubricating compositions, cutting tools for lathes, manufacturing tools, etc., can solve problems such as tool wear, cutting temperature rise, and extremely severe friction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

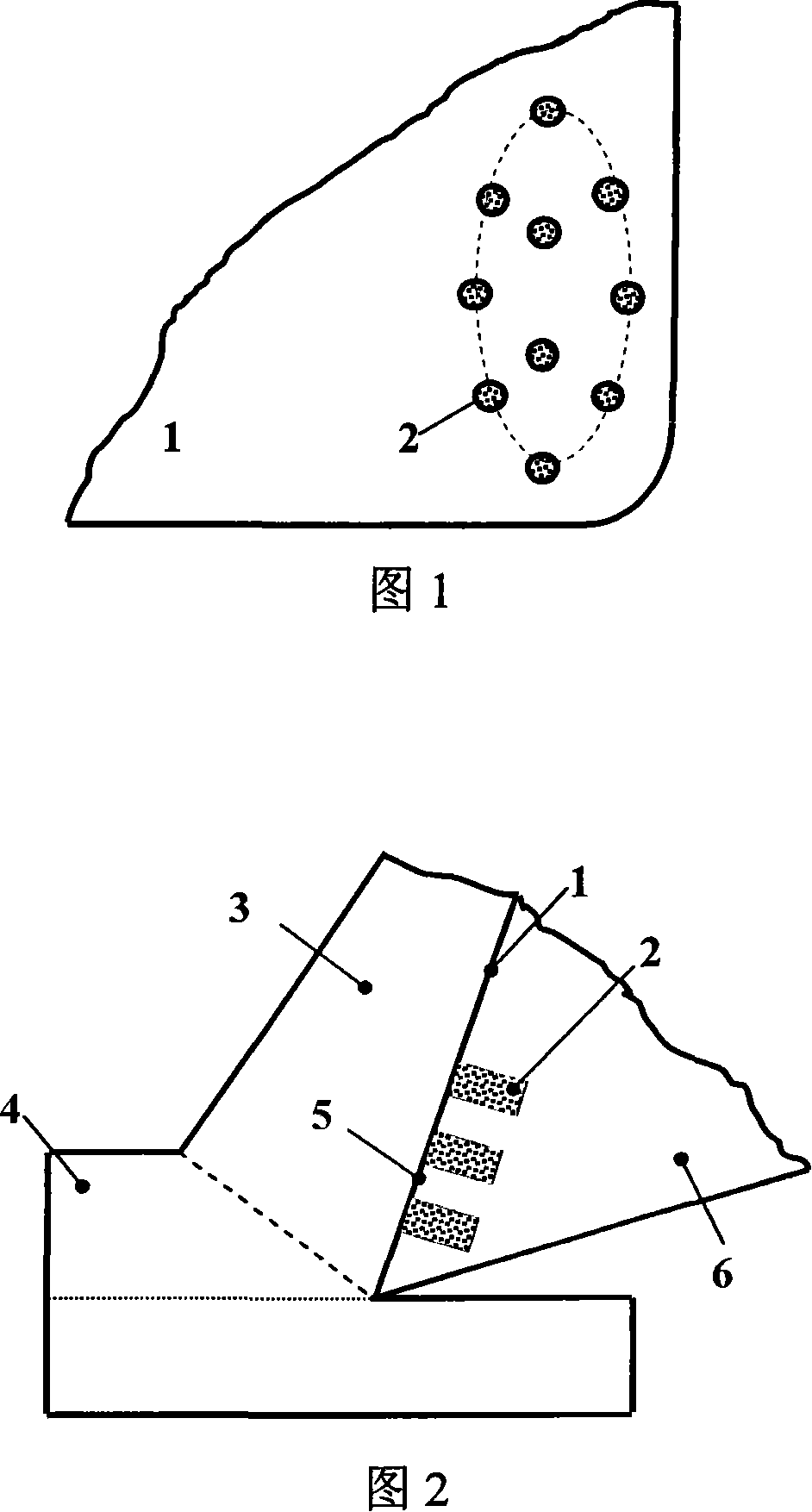

[0016] A micro-pool self-lubricating tool, the material of the tool 6 is high-speed steel, and the tool-chip contact area 5 of the rake face 1 of the tool has a plurality of microholes 2 for storing solid lubricant. Its preparation method is as follows:

[0017] 1. Use micro-EDM technology to process 18 micro-holes in the tool-chip contact area 5 of the rake face 1 of the high-speed steel tool. The diameter of each micro-hole is 120 μm, the depth of the micro-holes is 240 μm, and the hole spacing is 40 μm.

[0018] 2. Fill each micropore 2 with solid lubricant powder with a diameter of 2.0 μm, and the type of solid lubricant is TaS 2 .

[0019] 3. When the tool is used to dry-cut the workpiece 4, due to the high temperature of the cutting, the solid lubricant in the micropores in the tool-chip contact zone 5 softens and is dragged on the rake face of the tool, which will cause the tool-chip contact on the rake face of the tool. The zone forms a continuous solid lubricating l...

Embodiment 2

[0021] A kind of micro-pool self-lubricating cutter as described in Example 1, the difference is that the cutter material is cemented carbide, and its preparation method is as follows:

[0022] 1. Using micro-EDM technology to process 8 micro-holes in the tool-chip contact area on the rake face of the cemented carbide tool. The diameter of each micro-hole is 100 μm, the depth of the micro-holes is 200 μm, and the hole spacing is 60 μm.

[0023] 2. Fill each micropore with solid lubricant powder with a diameter of 1.5 μm, and the type of solid lubricant is WS 2 .

Embodiment 3

[0025] A kind of micro-pool self-lubricating cutter as described in Example 1, the difference is that the cutter material is ceramics, and its preparation method is as follows:

[0026] 1. Using laser processing technology to process 4 micro-holes in the tool-chip contact area on the rake face of the ceramic tool. The diameter of each micro-hole is 60 μm, the depth of the micro-holes is 120 μm, and the hole spacing is 80 μm.

[0027] 2. Fill each micropore with solid lubricant powder with a diameter of 1.0 μm, and the type of solid lubricant is MoS 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com