Catalyst for asymmetric synthesis, ligand used therefor and method for producing optically active compound by asymmetric synthetic reaction using the same

An optically active and compound technology, applied in asymmetric synthesis, catalytic reaction, organic chemical methods, etc., can solve the problems of poor selectivity and low yield of optically active aryl compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

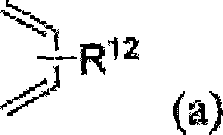

[0251] Synthesis of compounds 1-7

[0252] The synthetic schemes of compounds 1-7 are as described above.

[0253] Synthesis of compound 2

[0254] Into a 500ml round bottom flask was added NaH (60%, dispersed in mineral oil) (250mmol). The flask was filled with argon, then the compound was washed 2-3 times with THF. THF (100ml) was added and (R,R)-1,1'-binaphthol (50mmol) dissolved in THF (125ml) was added. After the mixture was stirred at 0°C for 1 hour, a solution of chloromethyl ether (125ml) in THF (30ml) was added dropwise. The mixture was then stirred at room temperature for 3 hours. Methanol and water were added, and the mixture was extracted 3 times with diethyl ether. The organic layer was washed with saturated aqueous sodium carbonate and saturated brine, and then dried over anhydrous sodium sulfate. After evaporation of the solvent, the residue was recrystallized from dichloromethane / pentane (92% yield).

[0255] Synthesis of compound 3

[0256] In a 2...

Embodiment 1

[0266] The synthetic method of compound 8, 9

[0267] Ammonium chloride (0.01 g) and compound 7 (1 mmol) were added to a 30 ml flask. The mixture was dissolved in toluene (10 ml), and hexamethylphosphoric triamide was added, followed by heating under reflux for 12 hours.

[0268] After cooling the mixture to room temperature, the solvent was distilled off. The residue was recrystallized from dichloromethane / pentane (75% yield, R=Me).

[0269] Structural formula and spectral data of R=Me (Compound 8)

[0270] Linked-pbosphoramidaite from(R)-BINOL C 46 h 38 N 2 o 5 P 2 Mol.Wt.: 761

[0271]

[0272] 1 H-NMR (CD 2 Cl 2 )δ=2.23-2.39(m, 12H), 4.82(d, J=13.3Hz, 2H), 5.02(d, J=13.3Hz, 2H), 7.07-7.39(m, 14H), 7.76-7.86(m , 6H), 8.15(s, 2H) 31 P-NMR (CD 2 Cl 2 )δ=150.8ppm MS (FAB), m / z (%): 43 (33), 266 (28), 282 (50), 329 (100), 373 (29), 388 (24), 716 (28) , 761 (M+H, 19) HRMS (FAB) calcd for C46H39N2O5P2 761.2334, found 761.2334

[0273] Structural formula and sp...

Embodiment 2

[0277] The synthetic method of compound 10

[0278] Add toluene (3ml), PCl 3 (2mmol), NEt 3 (4 mmol), the mixture was cooled to -60°C, a toluene solution of compound 7 was added dropwise, and the mixture was stirred for 2 hours. The mixture was warmed to room temperature, and the resulting salts were filtered off. The filtrate was cooled to -40°C, n-butyl lithium (2 mmol), diisopropylamine (3 mmol) were added, the mixture was warmed to room temperature and then stirred for 16 hours. After distilling off the solvent, the residue was recrystallized from dichloromethane / pentane to give compound 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com