Stone inclusion soil abrasive-proof anti-impact drill bit

An impact-resistant and drill bit technology, which is applied in the direction of drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of rocks that cannot be broken, easily worn or damaged, and low diamonds, and achieve the solution of drill bits' wear resistance and impact resistance. Abrasion and impact resistance properties, the effect of efficient cutting drilling operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

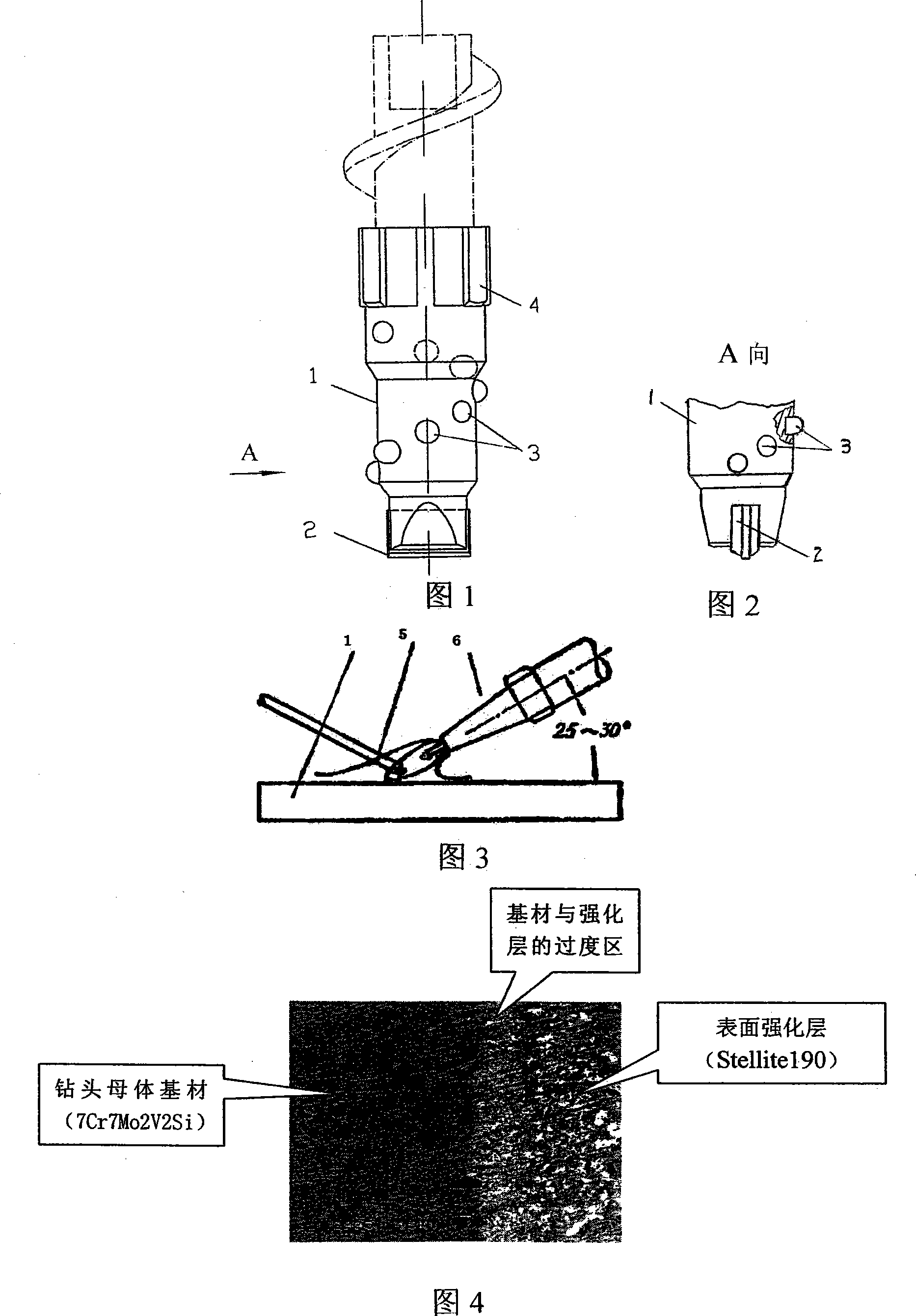

[0020] The preparation method of embodiment 1 rock soil drill bit

[0021] 1. Parent body surface strengthening treatment

[0022] (1) According to the requirements of the geometric dimensions of the drill bit, the 7Cr7Mo2V2Si steel bar of the corresponding diameter and length is cut to make the drill bit matrix, and the oxide layer on the surface is removed to expose the real metal surface.

[0023] (2) Preheat the parent body to 650°C (the surface is dark red) with an oxygen-acetylene flame (adjusted to a neutral flame), and then use a Stellite190 alloy electrode (commercially available) to tilt 30° on the surface of the parent body, and make the electrode end 3~6mm away from the surface of the base metal, melt the end of the electrode with an oxygen-acetylene flame (the angle between the welding tip and the surface of the base metal is about 25°~30°), and drop it on the surface of the heated base metal; according to this method Cladding is performed sequentially on the sur...

Embodiment 2

[0029] The impact wear test was carried out on the MPX-2000 testing machine. The test conditions are: dry friction and wear at room temperature (25°C), relative air humidity of RH60%, loads of 10N, 30N, 50N and 100N, sliding speeds of 2.68m / s, 3.99m / s and 8.00m / s, The total number of revolutions for each test is 1000 revolutions; the pair of friction parts is 120# white corundum test block. The test results show that the wear resistance of the drill base material made by the invention is 3-8 times that of the commonly used drill material 42CrMo alloy steel (tempering treatment, surface nitriding).

[0030] The drill bit produced by the present invention has been applied on a certain type of military rapid hole-forming drilling machine, and is used to complete the rapid drilling task in the rocky land zone (suburb of Xuzhou City, Jiangsu Province, Guanting Reservoir of Huailai County, Hebei Province, and Yangbajiao area of Tibet) . The application result shows that the wear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com