Technique for reclaiming vanadium and iron from high-vanadium high-iron steel slag

A new technology, steel slag technology, applied in the metallurgical field of vanadium extraction, can solve the problems of not being able to process in large quantities, limited thinking, difficult to control the production process, etc., to achieve comprehensive recycling and utilization is of great significance, realize comprehensive utilization, and reduce difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

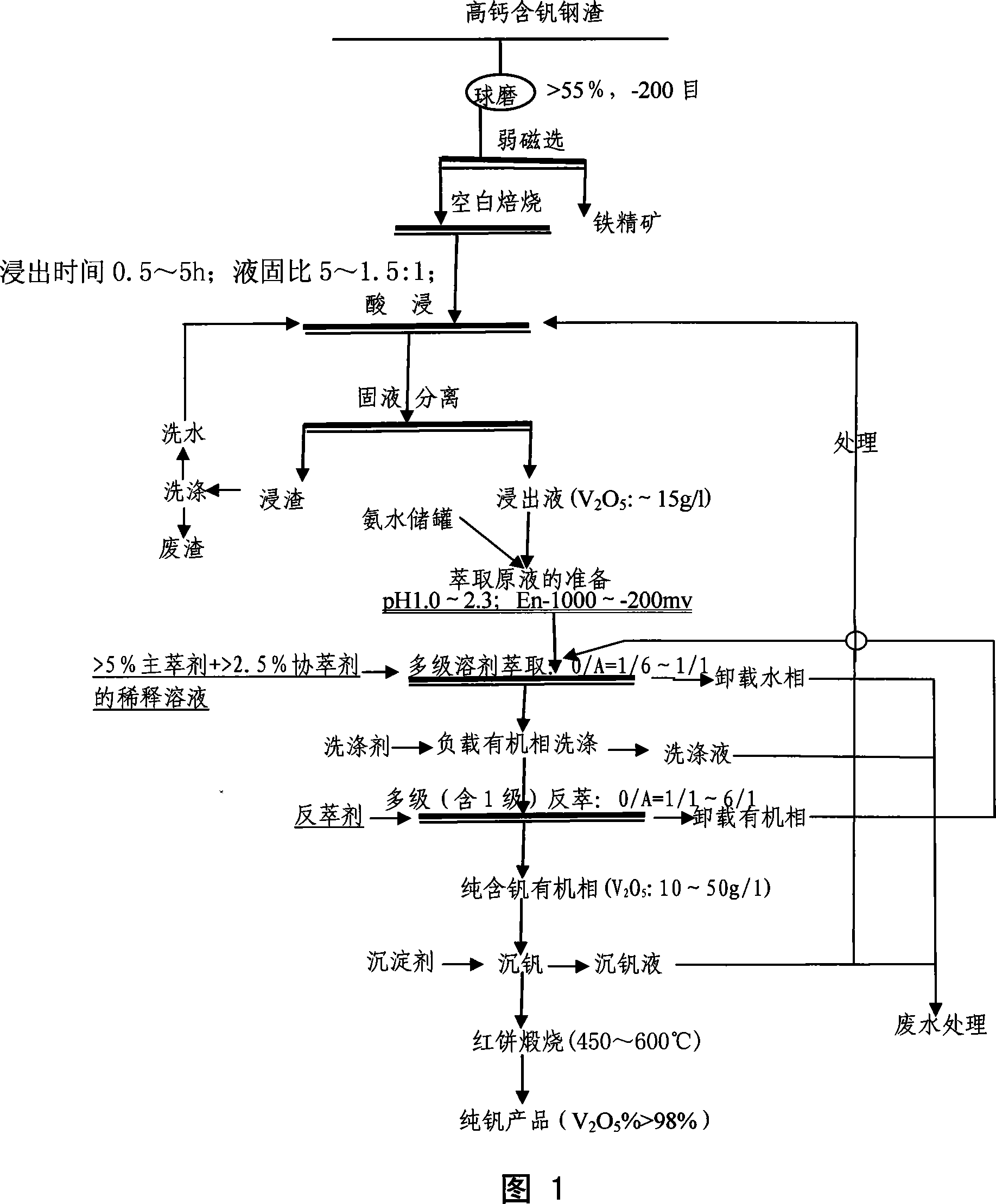

[0025] The object is massive steel slag from Sichuan Chuanwei Group. The steel slag is produced within a relatively short converter steelmaking time range. It is characterized by insufficient oxidation and relatively high vanadium content, which is obviously conducive to improving the economic benefits of vanadium extraction. Firstly, the steel slag raw material is crushed, and the dry ball mill equipment is used for grinding, and the fineness of the crushed product is 65% to -200 mesh;

[0026] Grinding products are subjected to dry weak magnetic separation, the magnetic field strength is 1800Oe, most of the vanadium enters the weak magnetic separation tailings, and the recovery rate reaches over 95%. At the same time, iron is enriched in the weak magnetic separation concentrate, and its yield is About 9%, the concentrate iron grade reaches 95%, which not only realizes the comprehensive recovery of iron, but also reduces the amount and concentration of iron in the acid leachin...

Embodiment 2

[0034] The target steel slag is produced within a relatively short converter steelmaking time range, and is characterized by insufficient oxidation and relatively high vanadium content. First, the steel slag raw material is crushed, and the dry ball mill equipment is used for grinding, and the fineness of the crushed product is 75% to -140 mesh.

[0035] Grinding products are subjected to low-temperature blank roasting, the roasting time is about 1.5h, and the temperature is 900°C.

[0036] The roasted clinker is subjected to dry weak magnetic separation, the magnetic field strength is 3900Oe, most of the vanadium enters the tailings of weak magnetic separation, and its recovery rate reaches 95%. At the same time, iron is enriched in the weak magnetic separation concentrate, and its yield is 8.6 %, the concentrate iron grade is about 94.3%, which not only realizes the comprehensive recovery of iron, but also reduces the amount and concentration of iron in the acid leaching sol...

Embodiment 3

[0043] First of all, crush a block of steel slag raw material in Sichuan, and use dry ball mill equipment for grinding, and the fineness of the crushed product is 80% to -140 mesh;

[0044] After grinding, the product is subjected to dry weak magnetic separation, the magnetic field strength is 2000Oe, most of the vanadium enters the tailings of weak magnetic separation, and the recovery rate reaches more than 95%. At the same time, iron is enriched in the weak magnetic separation concentrate, and its yield It is about 9%, and the iron grade of the concentrate reaches 95%, which not only realizes the comprehensive recovery of iron, but also reduces the amount and concentration of iron in the acid leaching solution.

[0045] Weak magnetic separation tailings are subjected to low-temperature blank roasting, the roasting time is about 2 hours, and the temperature is 800°C.

[0046] The clinker was roasted and then subjected to dry weak magnetic separation. It was found that the yi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com