Method for preparing zirconium oxide/mullite crystal whisker multiple phase material

A mullite whisker and zirconia technology, which is applied in the field of preparing zirconia/mullite whisker composite materials, can solve the problems of polluted waste liquid and waste residue, high cost of raw materials, complicated process, etc., and reduce high-temperature airtightness Environmental requirements, reduced raw material costs, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

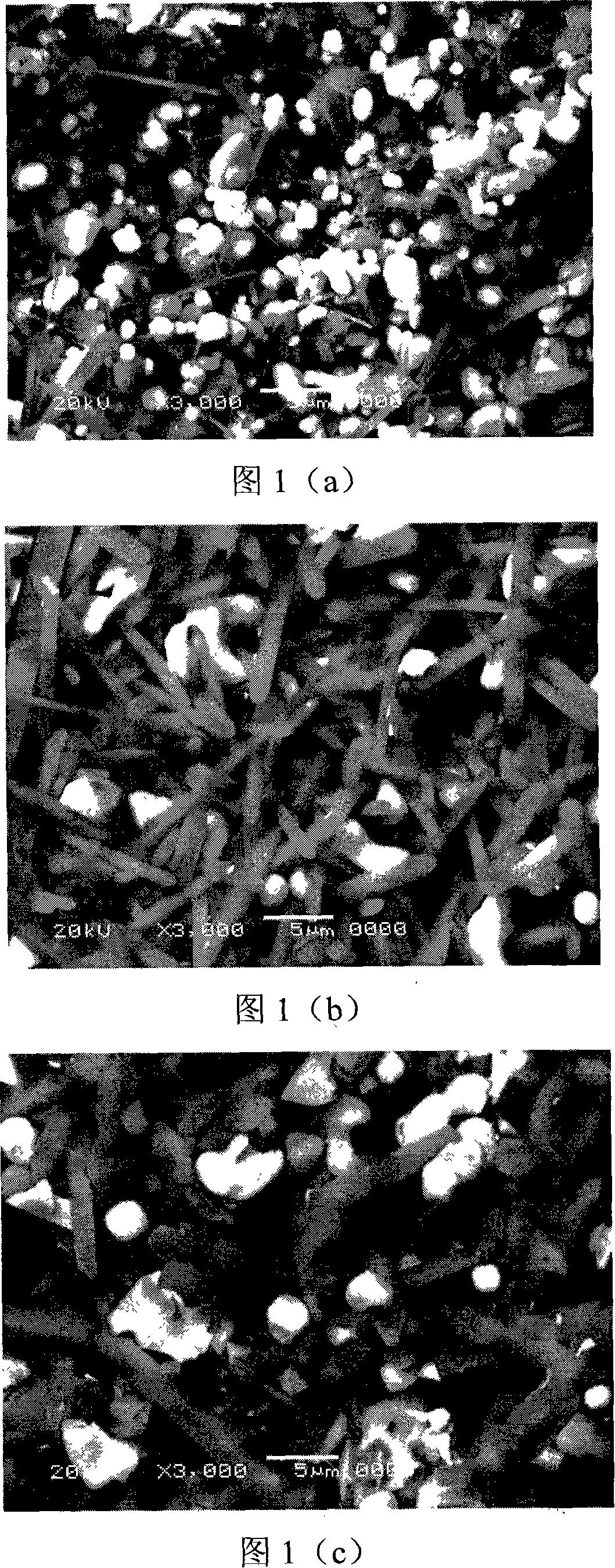

Image

Examples

Embodiment 1

[0019] Select the chemical composition as: Al 2 o 3 70wt%, SiO 2 12wt%, Fe 2 o 3 1.5wt%, TiO 2 4wt%, CaO 0.5wt%, MgO 0.2wt%, K 2 O+Na 2 The bauxite of O 1wt%, LOI (loss on ignition) 10.8wt%, and chemical composition is: ZrO 2 65wt%, SiO 2 33wt%, Fe 2 o 3 0.05wt%, Al 2 o 3 0.5wt%, TiO 2 0.2wt%, CaO 0.05wt%, MgO 0.05wt%, Na 2 O+K 2 O0.03wt%, zircon of 0.12wt% loss on ignition; the above-mentioned bauxite and zircon are crushed to a powder with an average particle size of 20 μm. Weigh 1000g of the above crushed bauxite and 471.01g of zircon, put the above raw materials into the ball mill tank of the planetary ball mill for co-grinding for 5 hours, the ball-to-material ratio is 60:1, and the speed is 1000 rpm. The above mixed powder after co-grinding is machine pressed into a block green body under a pressure of 30 MPa. Then put the above block green body in a box-type resistance furnace for heat treatment, the heating rate is 10°C / min, the heat treatment ...

Embodiment 2

[0021] Select the chemical composition as: Al 2 o 3 75wt%, SiO 2 8wt%, Fe 2 o 3 1wt%, TiO 2 3wt%, CaO 0.5wt%, MgO 0.2wt%, K 2 O+Na 2 The bauxite of O 1wt%, LOI (loss on ignition) 11.3wt%, and chemical composition is: ZrO 2 68wt%, SiO 2 30wt%, Fe 2 o 3 0.15wt%, Al 2 o 3 1wt%, TiO 2 0.4wt%, CaO 0.05wt%, MgO 0.05wt%, Na 2 O+K 2 O 0.03wt%, zircon with an ignition loss of 0.32wt%; the above-mentioned bauxite and zircon are crushed to a powder with an average particle size of 25 μm. Weigh 1000g of the crushed bauxite and 723.18g of zircon, and put the above raw materials into the ball mill tank of the planetary ball mill for co-milling for 10 hours, the ball-to-material ratio is 40:1, and the speed is 900 rpm. The above-mentioned mixed powder after co-grinding is machine-pressed into a block green body under a pressure of 40 MPa. Then, the above block green body was placed in a box-type resistance furnace for heat treatment, the heating rate was 10°C / min, th...

Embodiment 3

[0023] Select the chemical composition as: Al 2 o 3 80wt%, SiO 2 3wt%, Fe 2 o 3 1wt%, TiO 2 3wt%, CaO 0.5wt%, MgO 0.2wt%, K 2 O+Na 2 The bauxite of O 1wt%, LOI (loss on ignition) 11.3wt%, and chemical composition is: ZrO 2 67wt%, SiO 2 31wt%, Fe 2 o 3 0.1wt%, Al 2 o 3 1wt%, TiO 2 0.4wt%, CaO 0.05wt%, MgO 0.05wt%, Na 2 O+K 2 O 0.03wt%, zircon with an ignition loss of 0.37wt%; the above-mentioned bauxite and zircon are crushed to a powder with an average particle size of 30 μm. Weigh 1000 g of the crushed bauxite and 926.97 g of zircon, put the above raw materials into the ball mill tank of the planetary ball mill for co-grinding for 15 hours, the ball-to-material ratio is 30:1, and the speed is 700 rpm. The above-mentioned mixed powder after co-grinding is machine-pressed into a block green body under a pressure of 50 MPa. Then put the above block green body in a box-type resistance furnace for heat treatment, the heating rate is 15°C / min, the heat treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com