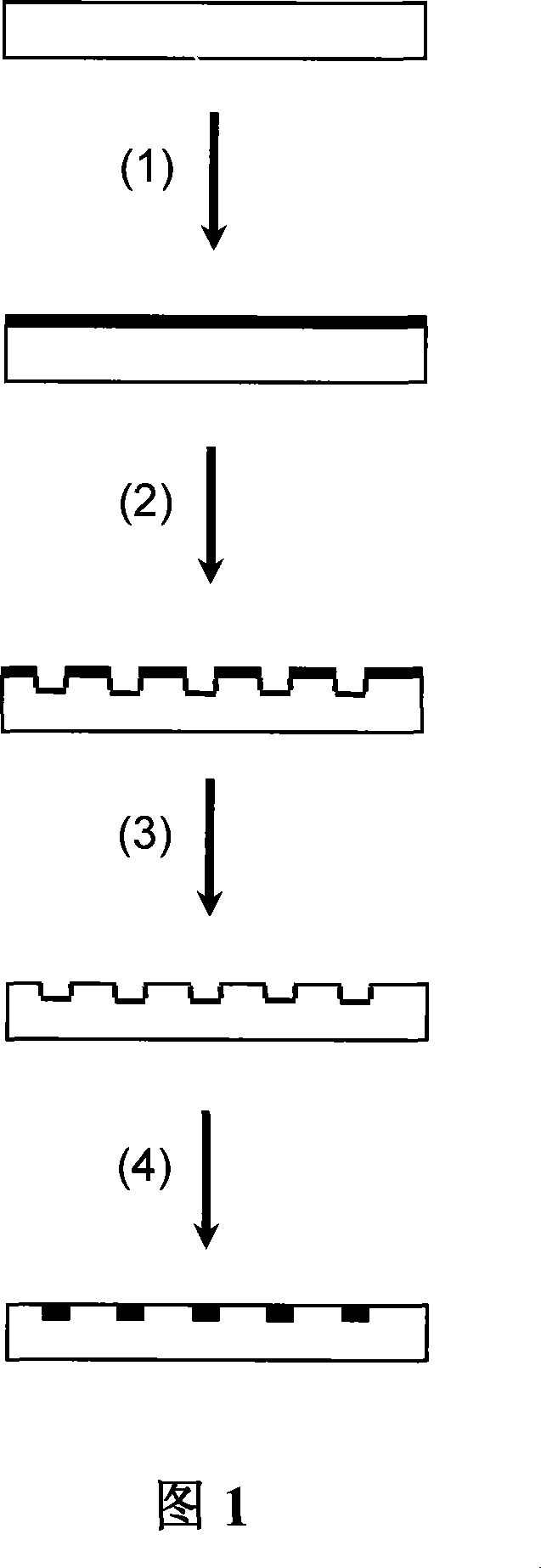

Method for realizing selectivity metallization on glass surface by femto-second laser

A femtosecond laser, glass surface technology, applied in the field of glass metallization and femtosecond laser micromachining, can solve problems to be improved, achieve good selectivity and adhesion, high processing accuracy, good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The concentration of the silver nitrate solution used for immersion is 0.5mol / l, and the immersion time is 10min; when the femtosecond laser directly writes patterns on the silver nitrate film, its wavelength is 800nm, the pulse width is 40fs, and the peak power density is 2.4×10 15 W / cm 2 , the scanning speed is 60μm / s; the solvent used to remove the unirradiated silver nitrate film is acetone→alcohol→distilled water in sequence, and the cleaning time of each solvent is 3min, and ultrasonic wave is used as an auxiliary means; the composition of the electroless copper plating solution is copper sulfate (CuSO 4 ·5H 2 O) 5g / l, sodium ethylenediaminetetraacetate (EDTA 2Na) 14g / l, formaldehyde (HCHO) 5g / l, 2-2'bipyridine 0.02g / l, polyethylene glycol (PEG4000) 0.05g / l l. The pH value is 12.5 (adjusted by 1% NaOH solution); the plating time is 45 minutes, and the plating temperature is 40°C. Experiments show that the Cu thin film is conductive (to achieve selective metalli...

Embodiment 2

[0042] The concentration of the fresh silver nitrate solution used for immersion is 1mol / l, and the immersion time is 10min; when the femtosecond laser directly writes patterns on the silver nitrate film, the wavelength is 800nm, the pulse width is 40fs, and the peak power density is 4.0×10 15 W / cm 2 , the scanning speed is 60μm / s; the solvent used to remove the unirradiated silver nitrate film is acetone→alcohol→distilled water in sequence, and the cleaning time of each solvent is 3min, and ultrasonic wave is used as an auxiliary means; the composition of the electroless copper plating solution is copper sulfate (CuSO 4 ·5H 2O) 7.5g / l, sodium ethylenediaminetetraacetate (EDTA 2Na) 14g / l, formaldehyde (HCHO) 7.5g / l, 2-2'bipyridine 0.03g / l, polyethylene glycol (PEG4000) 0.05 g / l. The pH value is 12.5 (adjusted by 1% NaOH solution); the plating time is 30 minutes, and the plating temperature is 40°C. Experiments show that the Cu thin film conducts electricity (to achieve sele...

Embodiment 3

[0044] The concentration of the silver nitrate solution used for immersion is 1mol / l, and the immersion time is 20min; when the femtosecond laser directly writes patterns on the silver nitrate film, the wavelength is 800nm, the pulse width is 40fs, and the peak power density is 6.4×10 15 W / cm 2 , scanning speed 60μm / s; the solvent used to remove the unirradiated silver nitrate film is acetone→alcohol→distilled water in turn, and the cleaning time of each solvent is 5min, and ultrasonic wave is used as an auxiliary means; the composition of the electroless copper plating solution is: copper sulfate (CuSO 4 ·5H 2 O) 5g / l, sodium ethylenediaminetetraacetate (EDTA 2Na) 14g / l, formaldehyde (HCHO) 5g / l, 2-2'bipyridine 0.03g / l, polyethylene glycol (PEG4000) 0.05g / l l. The pH value is 12.5 (adjusted by 1% NaOH solution); the plating time is 15 minutes, and the plating temperature is 50°C. Experiments show that the Cu thin film is conductive (to achieve selective metallization of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com