Vitamin and mineral nutrient complementing granule or tablet for children and teen-agers, and preparation method thereof

A nutritional supplement and vitamin technology, applied in food preparation, food science, pill delivery, etc., can solve problems such as children's boredom and affecting product effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

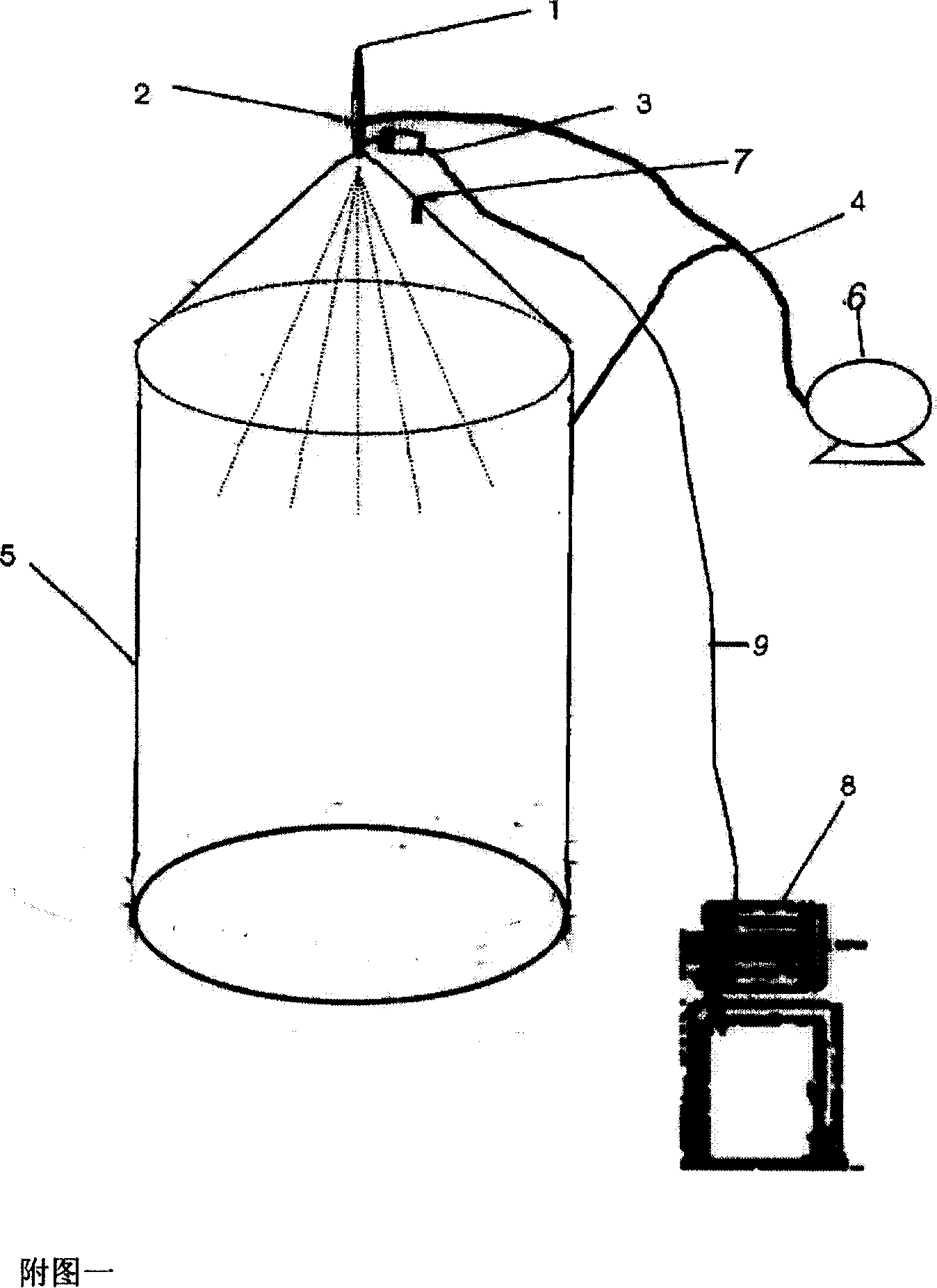

Image

Examples

Embodiment 1

[0023] Example 1: Preparation of lactose adjuvant granules containing neutral carbon dioxide gas

[0024] 1. Put 3kg of lactose and 2kg of sucrose into the autoclave, and add 1 liter of water at the same time;

[0025] 2. Slowly increase the temperature of the reactor to about 120°C to slowly dissolve the lactose into a liquid state, and keep the temperature to evaporate the water so that the final water content is 2%;

[0026] 3. Introduce neutral carbon dioxide gas at 50 atmospheres, and stir the lactose syrup at a speed of 400 revolutions per minute;

[0027] 4. Stop stirring after 7 minutes, reduce the pressure of the autoclave to 25 atmospheres, and pour 15°C cold water into the wall of the autoclave to cool the lactose syrup;

[0028] 5. After the lactose is cooled and agglomerated into small pieces of various sizes, pour out the lactose, use a medium-speed mill to grind the small pieces of lactose into granules, and collect the lactose that can pass through a 20-mesh s...

Embodiment 2

[0029] Embodiment 2: Preparation of lactose, sucrose and starch mixed auxiliary material granules containing neutral carbon dioxide gas

[0030] 1. Put 3kg of lactose, 1kg of sucrose and 1kg of cornstarch into the autoclave, and add 1.5 liters of water at the same time;

[0031] 2. Slowly increase the temperature of the reactor to about 120°C to slowly dissolve the solid powder into a liquid state, and keep the temperature to evaporate the water so that the final water content is 3%;

[0032] 3. Introduce neutral carbon dioxide gas at 50 atmospheres, and stir the lactose syrup at a speed of 400 revolutions per minute;

[0033] 4. Stop stirring after 7 minutes, reduce the pressure of the autoclave to 25 atmospheres, and pour 15°C cold water into the wall of the autoclave to cool the lactose syrup;

[0034]5. After the syrup is cooled and agglomerated into small pieces of various sizes, pour it out, use a medium-speed mill to grind the small pieces into particles, and collect p...

Embodiment 3

[0035] Example 3: Preparation of lactose, sucrose, gelatin and starch mixed excipient granules containing neutral carbon dioxide gas, adding gelatin is to increase the compression resistance of the obtained granules and maintain the integrity of the granules during the tableting process

[0036] 1. Put 2kg lactose, 1kg sucrose, 1kg gelatin and 1kg cornstarch into the autoclave, and add 3 liters of water at the same time;

[0037] 2. Slowly increase the temperature of the reactor to about 120°C to slowly dissolve the solid powder into a liquid state, and keep the temperature to evaporate the water so that the final water content is 3%;

[0038] 3. Introduce neutral carbon dioxide gas at 50 atmospheres, and stir the lactose syrup at a speed of 400 revolutions per minute;

[0039] 4. Stop stirring after 8 minutes, reduce the pressure of the autoclave to 25 atmospheres, and pour 15°C cold water into the wall of the autoclave to cool the lactose syrup;

[0040] 5. After the syrup ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com