Surrounding rock pre-treatment method for TBM passing through round-tunnel section with strong rockburst risk

A pretreatment and rockburst technology, applied in blasting, earth-moving drilling, mining equipment, etc., can solve problems such as high rockburst risk, achieve safe construction environment, relax rock mass, and reduce stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

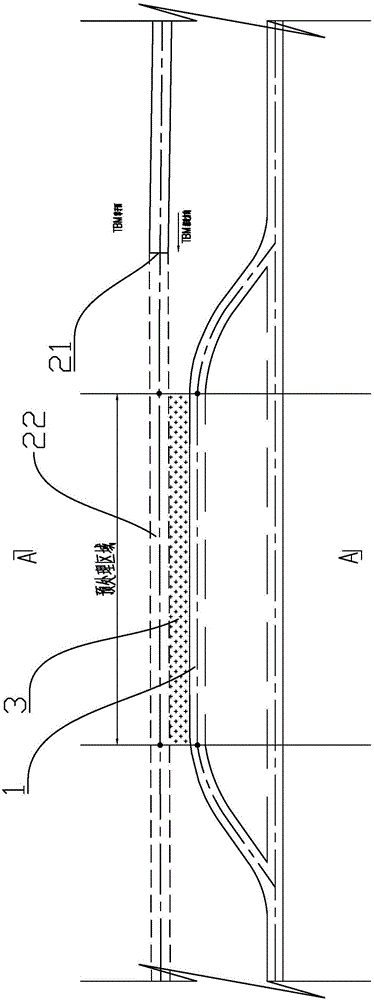

[0020] This embodiment is a surrounding rock pretreatment method for a TBM to bypass a tunnel section with a strong rockburst risk. like figure 1 , figure 2 As shown, when the clear distance between the bypass tunnel 1 and the planned tunnel 22 on the TBM excavation design line is small, and there is a strong risk of rockburst during the excavation of the existing tunnel 1 (bypass tunnel), it can be Adopt the method of present embodiment to carry out pretreatment to the surrounding rock of this tunnel section, concrete steps are as follows:

[0021] 1. Determine the pretreatment area. The area where the net distance between the tunnel 22 to be constructed and the adjacent existing tunnel 1 is less than 2 times the diameter (D) of the tunnel 22 to be constructed by the TBM in the direction of TBM excavation is the pretreatment area. The pretreatment area is divided into a construction section of 10m, and the construction is carried out in sections.

[0022] 2. When the TBM ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com