Method of lithium ion secondary battery anode active compound coating oxide layer

A positive electrode active material and secondary battery technology, applied in chemical instruments and methods, electrode manufacturing, chemical/physical/physicochemical processes, etc., can solve the problems of high energy consumption, large pollution, low energy consumption, etc., and achieve energy consumption Low, little pollution, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

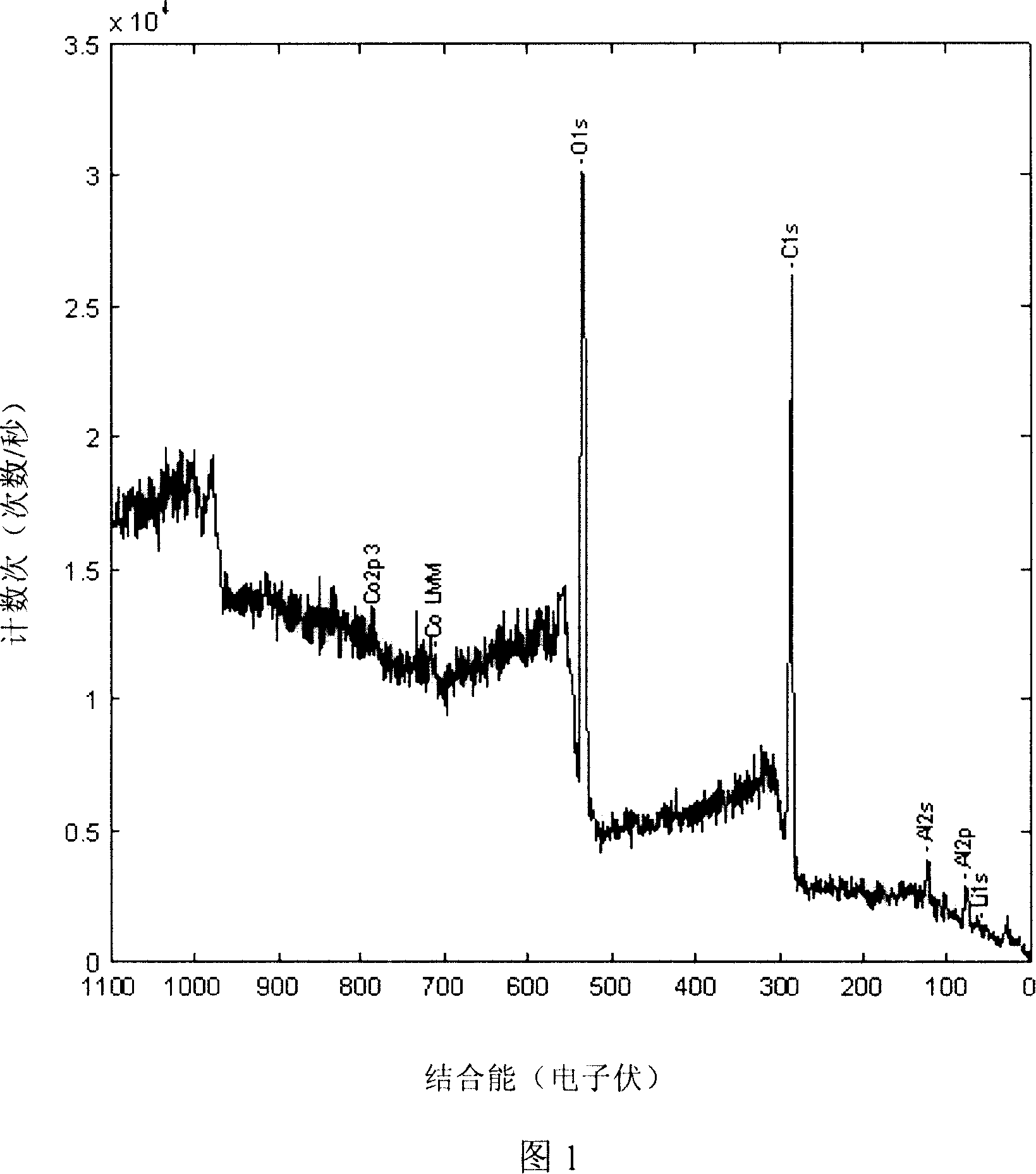

[0025] This example illustrates the method for coating the oxide layer with the positive electrode active material of the lithium ion secondary battery provided by the present invention.

[0026] Follow the steps below to coat the oxide layer on the positive electrode active material:

[0027](1) Use deionized water as a solvent to prepare a 0.05 mol / liter sodium metaaluminate solution, add 10% by weight of absolute ethanol as a dispersant to the obtained solution, and stir and mix evenly.

[0028] (2) The molar ratio of all aluminum elements in the sodium metaaluminate solution described in (1) and the lithium element in the lithium cobalt oxygen is that the ratio of 1: 100 weighs the lithium cobalt oxygen particle that diameter is 5.5-19 micron, stirs Added to the solution obtained in (1) under certain conditions to obtain a uniform suspension.

[0029] (3) in the suspension that 500 milliliters (2) obtains, pass into carbon dioxide gas, the flow rate of carbon dioxide gas ...

Embodiment 2

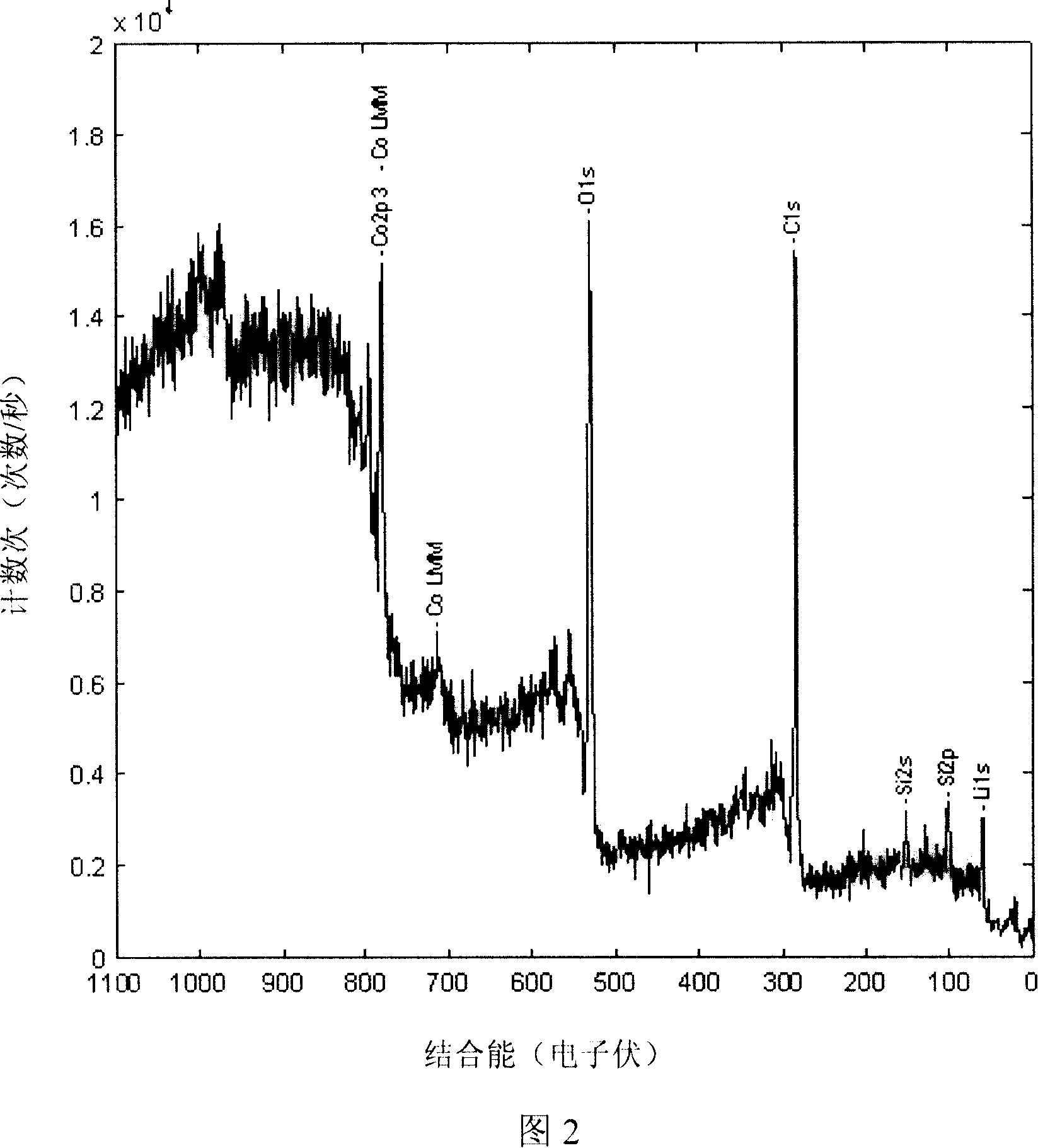

[0034] This example illustrates the method for coating the oxide layer with the positive electrode active material of the lithium ion secondary battery provided by the present invention.

[0035] Follow the steps below to coat the oxide layer on the positive electrode active material:

[0036] (1) Use deionized water as a solvent to prepare a 0.03 mol / liter sodium silicate solution, add 5% by weight propanol to the obtained solution as a dispersant, and stir and mix evenly.

[0037] (2) According to (1) described in the sodium silicate solution, the ratio of the molar ratio of all the silicon elements in the sodium silicate solution to the lithium element in the lithium cobalt oxygen is 2: 100. Weigh the lithium cobalt oxygen particles with a diameter of 6.5-18 microns. Add it to the solution obtained in (1) to obtain a uniform suspension.

[0038] (3) Add 0.1 mol / liter of acetic acid dropwise to the suspension obtained in 500 milliliters of (2), stir while adding dropwise, a...

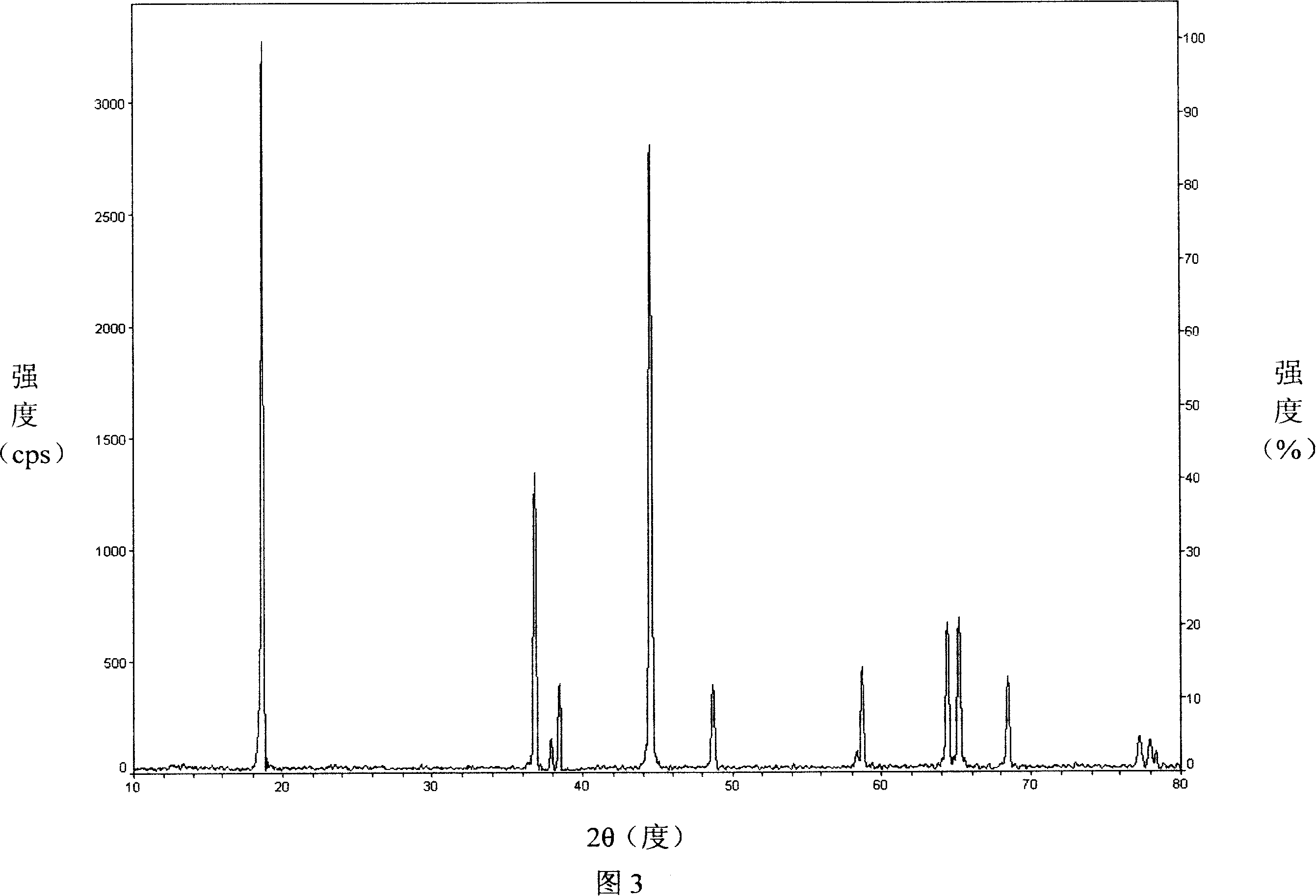

Embodiment 3-8

[0042] Examples 3-8 were prepared according to the method of Example 1, and the differences are shown in Table 1.

[0043] Table 1

[0044] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com