Method for fabricating pixel structure

A technology of a pixel structure and a manufacturing method, which is applied in the fields of semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of high cost of large-size photomasks, the manufacturing cost of pixel structure 90 cannot be reduced, and the cost of photomasks is expensive. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

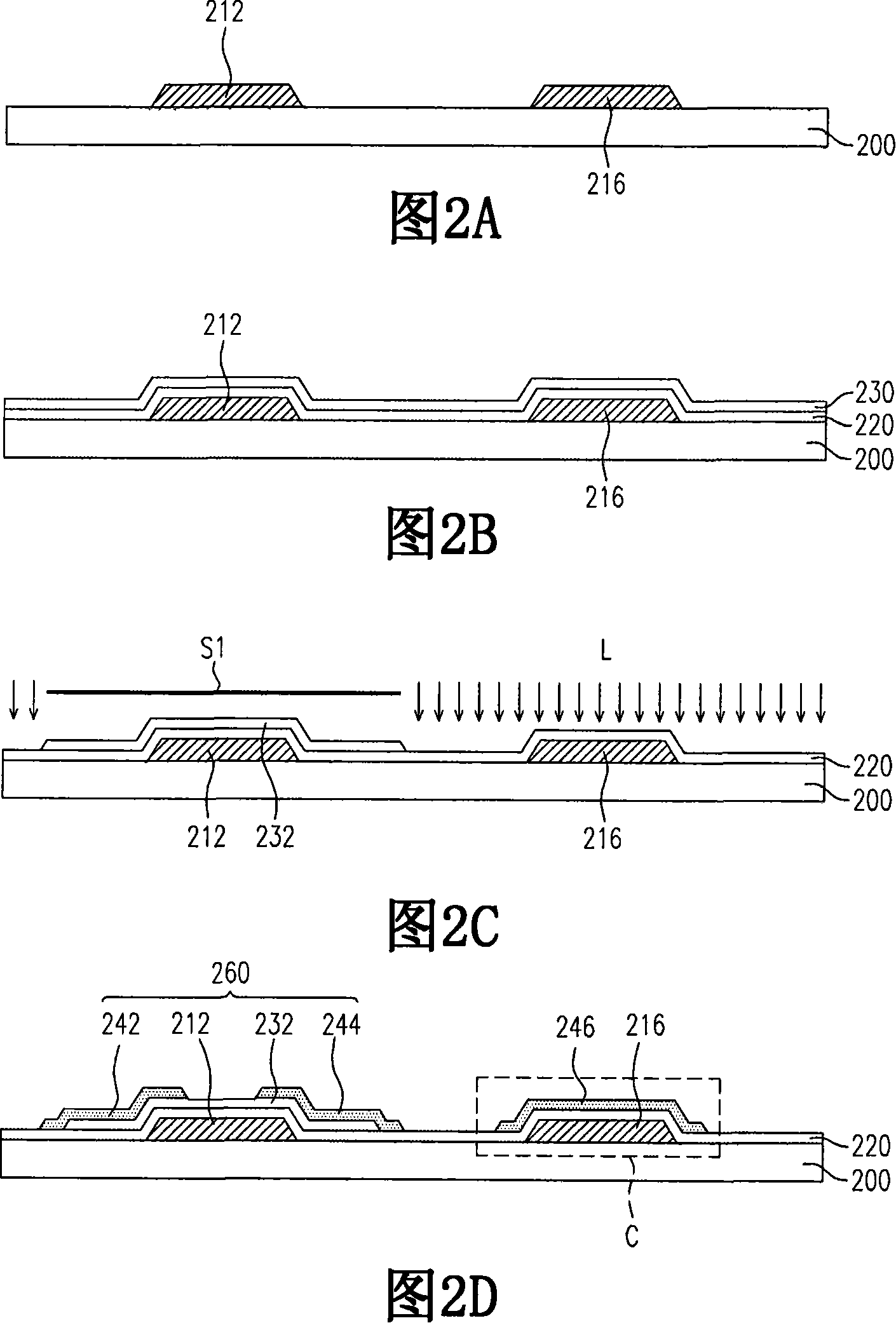

[0056] 2A to 2G are schematic diagrams of a manufacturing method of a pixel structure of the present invention. Referring to FIG. 2A , firstly, a substrate 200 is provided, and the material of the substrate 200 is hard or soft materials such as glass and plastic. Next, a gate 212 is formed on the substrate 200 . In this embodiment, it also includes forming the lower capacitor electrode 216 while forming the gate 212 .

[0057] Next, referring to FIG. 2B , a gate dielectric layer 220 is formed on the substrate 200 to cover the gate electrode 212 and the lower capacitor electrode 216, wherein the gate dielectric layer 220 is, for example, formed by chemical vapor deposition (CVD) or other suitable film deposition techniques, and the material of the gate dielectric layer 220 is, for example, a dielectric material such as silicon oxide, silicon nitride, or silicon oxynitride. Next, a semiconductor layer 230 is formed on the gate dielectric layer 220 . In this embodiment, the ma...

no. 2 example

[0067] 6A to 6H are schematic diagrams of a manufacturing method of the pixel structure in the second embodiment of the present invention. Since the steps in FIG. 6A-FIG. 6E are similar to those in FIG. 2A-FIG. 2E of the first embodiment, their descriptions are omitted here.

[0068] Referring to FIG. 6F , after the patterned protection layer 272 is formed, the patterned protection layer 272 is baked so that the patterned protection layer 272 has a mushroom-shaped top surface M. Referring to FIG. The patterned passivation layer 272 after baking exhibits a pattern in which the top surface of the patterned passivation layer 272 is slightly larger than the bottom surface thereof, so that the top surface of the patterned passivation layer 272 substantially presents the above-mentioned mushroom-shaped top surface M. It is worth mentioning that in practice, manufacturing process errors such as temperature, heating speed, and heating time of the baking process must be considered. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com