Layered thin film structure, layered thin film forming method, film forming system and storage medium

A technology of laminated structure and film, applied in the direction of coating, thin material processing, transportation and packaging, can solve the problems of inability to increase the height, difficult to meet the requirements of step coverage, insufficient adhesion, etc., to achieve high adhesion, restraint Film peeling, improved step coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, an embodiment of the multilayer structure of the thin film, its forming method, film forming apparatus, and storage medium of the present invention will be described with reference to the drawings.

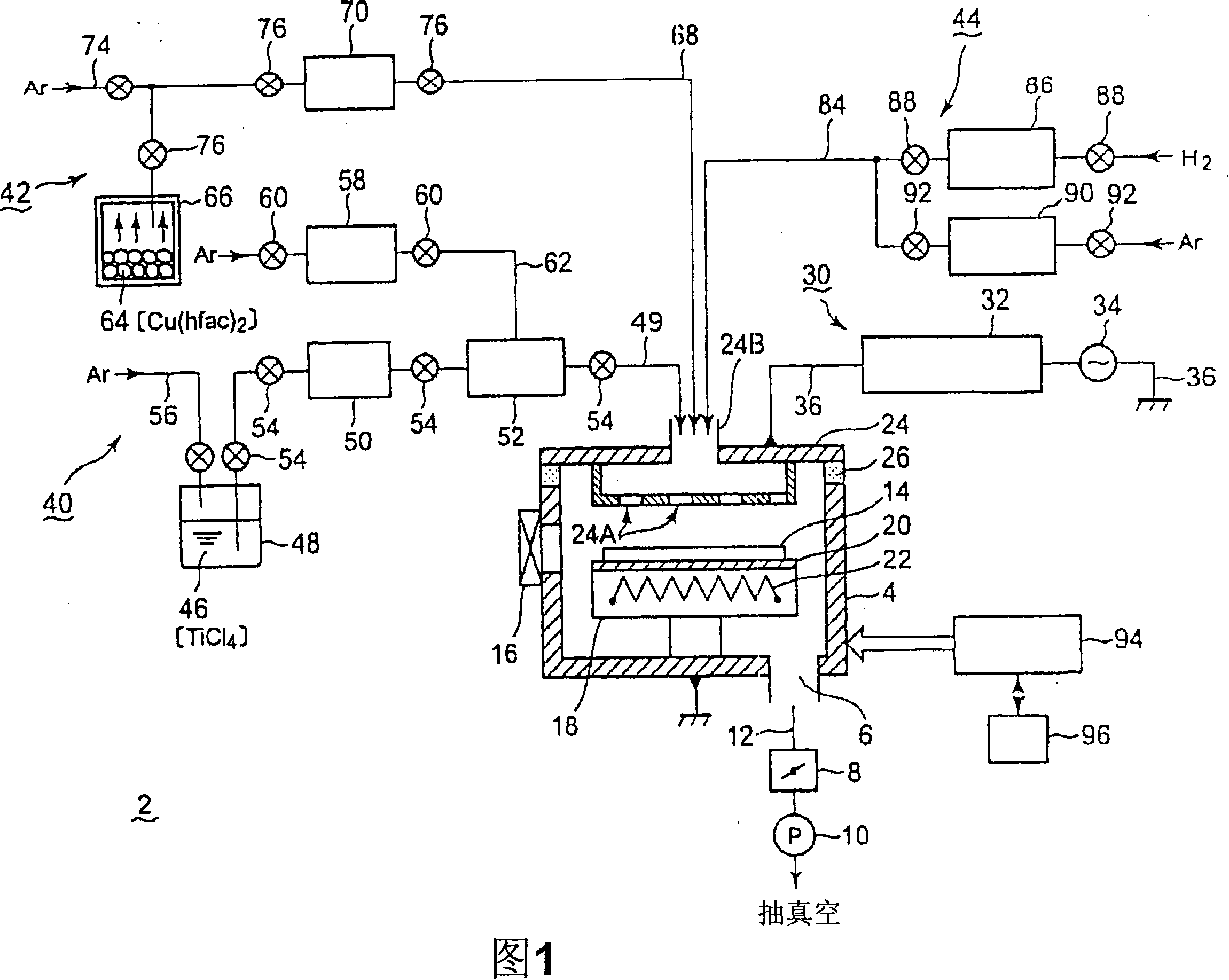

[0035] FIG. 1 is a schematic configuration diagram showing an example of a film forming apparatus of the present invention.

[0036]First, the film forming apparatus 2 of the present invention will be described. The film forming apparatus 2 has a cylindrical processing container 4 formed of, for example, aluminum or the like. The processing container 4 is grounded, and an exhaust port 6 is formed at the bottom thereof. A vacuum exhaust system 12 provided with a pressure control valve 8 and a vacuum pump 10 in the middle is connected to the exhaust port 6, and can vacuum the inside of the processing container 4 and set it to an arbitrary pressure.

[0037] In addition, a gate valve 16 is provided on the side wall of the processing container 4 to open and close ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com