High-cleanliness environmentally-friendly metal surface oil dirt cleaning agent and preparation method thereof

A kind of oil stain cleaning agent and metal surface technology, applied in the field of cleaning agent, can solve the problems of low cleaning efficiency, large environmental pollution, single function, etc., and achieve the effect of small human irritation, wide application range and strong decontamination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

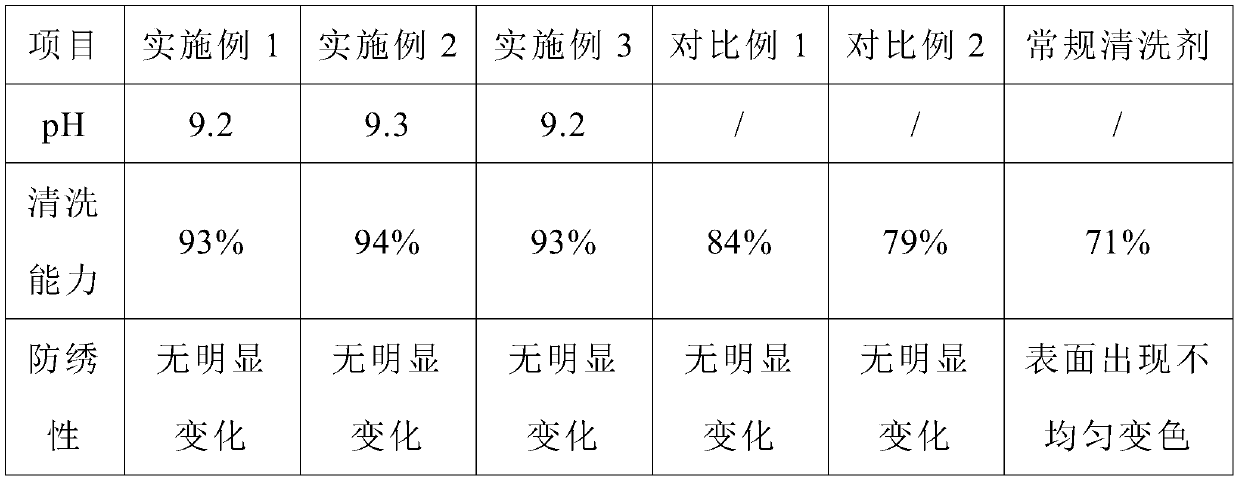

Examples

Embodiment 1

[0046] S1: Prepare materials;

[0047] S2: Preparation of Surfactant A:

[0048] Take cardanol, epichlorohydrin and tetrabutylammonium bromide, mix and stir for 10 minutes, slowly raise the temperature to 95°C, continue the reaction for 3 hours, and distill under reduced pressure to obtain material A;

[0049] Take material A, dissolve dimethylamine, stir for 5 minutes, add sodium hydroxide, raise the temperature to 60°C, stir and react for 7 hours, wash until neutral, and distill off water under reduced pressure to obtain material B;

[0050] Take material B, dissolve it in isopropanol, add 3-chloro-2-hydroxypropanesulfonate sodium, stir for 10 minutes, slowly raise the temperature to 85°C, adjust the pH to 8, react at constant temperature for 20 hours, wash, and suction filter to obtain surfactant A ;

[0051] S3: Preparation of auxiliary agent A:

[0052] Take dimethylformamide, add xanthan gum, stir for 12 hours under nitrogen atmosphere, the stirring temperature is 25°...

Embodiment 2

[0062] S1: Prepare materials;

[0063] S2: Preparation of Surfactant A:

[0064] Take cardanol, epichlorohydrin and tetrabutylammonium bromide, mix and stir for 15 minutes, slowly raise the temperature to 97°C, continue the reaction for 3.5 hours, and distill under reduced pressure to obtain material A;

[0065] Take material A, dissolve dimethylamine, stir for 8 minutes, add sodium hydroxide, raise the temperature to 62°C, stir for 7.5 hours, wash until neutral, and distill off water under reduced pressure to obtain material B;

[0066] Take material B, dissolve it in isopropanol, add 3-chloro-2-hydroxypropanesulfonate sodium, stir for 12 minutes, slowly raise the temperature to 87°C, adjust the pH to 8.5, react at constant temperature for 22 hours, wash, and suction filter to obtain surfactant A ;

[0067] S3: Preparation of auxiliary agent A:

[0068] Take dimethylformamide, add xanthan gum, stir for 13 hours under nitrogen atmosphere, the stirring temperature is 27°C, t...

Embodiment 3

[0078] S1: Prepare materials;

[0079] S2: Preparation of Surfactant A:

[0080] Take cardanol, epichlorohydrin and tetrabutylammonium bromide, mix and stir for 20 minutes, slowly raise the temperature to 98°C, continue the reaction for 4 hours, and distill under reduced pressure to obtain material A;

[0081] Take material A, dissolve dimethylamine, stir for 10 minutes, add sodium hydroxide, raise the temperature to 65°C, stir for 8 hours, wash until neutral, and distill off water under reduced pressure to obtain material B;

[0082] Take material B, dissolve it in isopropanol, add 3-chloro-2-hydroxypropanesulfonate sodium, stir for 15 minutes, slowly raise the temperature to 88°C, adjust the pH to 9, react at constant temperature for 24 hours, wash, and suction filter to obtain surfactant A ;

[0083] S3: Preparation of auxiliary agent A:

[0084] Take dimethylformamide, add xanthan gum, stir for 14h under nitrogen atmosphere, the stirring temperature is 28°C, then add 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com