Two-stage series reactor for synthesis of natural gas hydrates

A series reactor, natural gas technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of hydrate ice blockage and difficulty in timely drainage of spray reactors.

Inactive Publication Date: 2010-09-15

HARBIN INST OF TECH

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The purpose of the present invention is to provide a two-stage series reactor for natural gas hydrate synthesis, to overcome the existing bubbling reactor which is easy to cause hydrate ice blockage on the orifice plate and the spray reactor which is difficult to discharge hydrate in time heat of reaction defect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

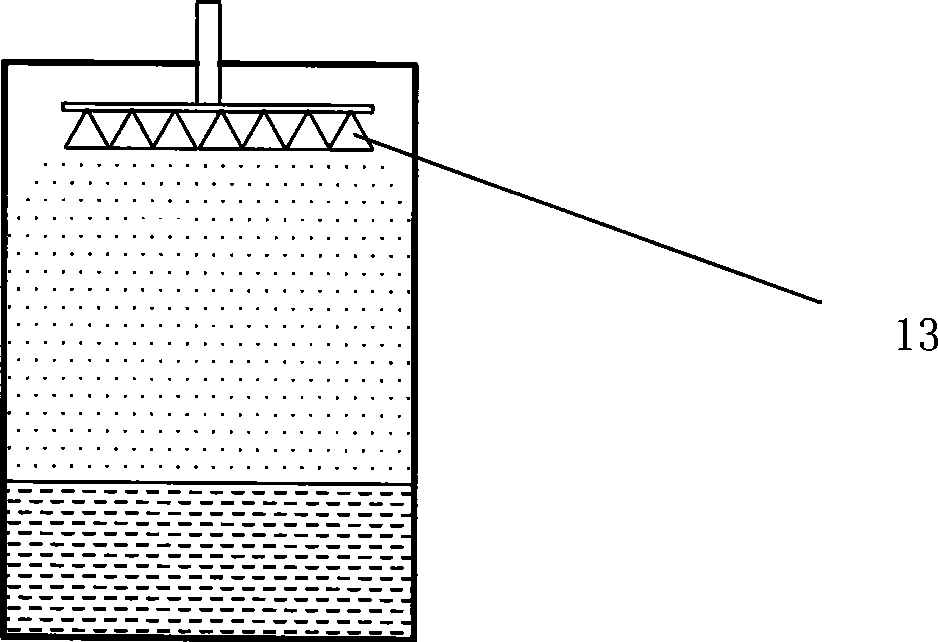

The invention relates to a double-stage and serial connection reactor synthesized by natural gas and hydrate relating to a synthesized reactor of natural gas and hydrate. The invention overcomes the defectiveness of the existing reactors of bubbling type that the hydrate is easily iced and blocked on the surface of an orifice plate and the defectiveness of the existing reactor of spraying type that the hydrate heat of reaction is difficult to be drained away. The double-stage and serial connection reactor consists of a No.1 reactor, a No.2 reactor, a water inlet pipe, a natural gas inlet pipeand a transfusion pipe. The No.1 reactor comprises a No. 1 autoclave body, a No. 1 spray device and an orifice plate device, with the No.1 spray device being arranged at the top of the inner chamber of the No.1 autoclave body and communicated with the water inlet pipe and the orifice plate being arranged at the bottom of the inner chamber of the No.1 autoclave body and communicated with the natural gas inlet pipe; the No.2 reactor comprises a No.2 autoclave body, a No.2 spray device and a stirring device, with the No.2 spray device being arranged at the top of the inner chamber of the No.2 autoclave body and communicated with the water inlet pipe and the stirring device being arranged at the bottom of the inner chamber of the No.2 autoclave body and the bottom of the No.2 autoclave body being communicated with the natural gas inlet pipe. The side wall of the No.1 autoclave body is communicated with that of the No.2 autoclave body.

Description

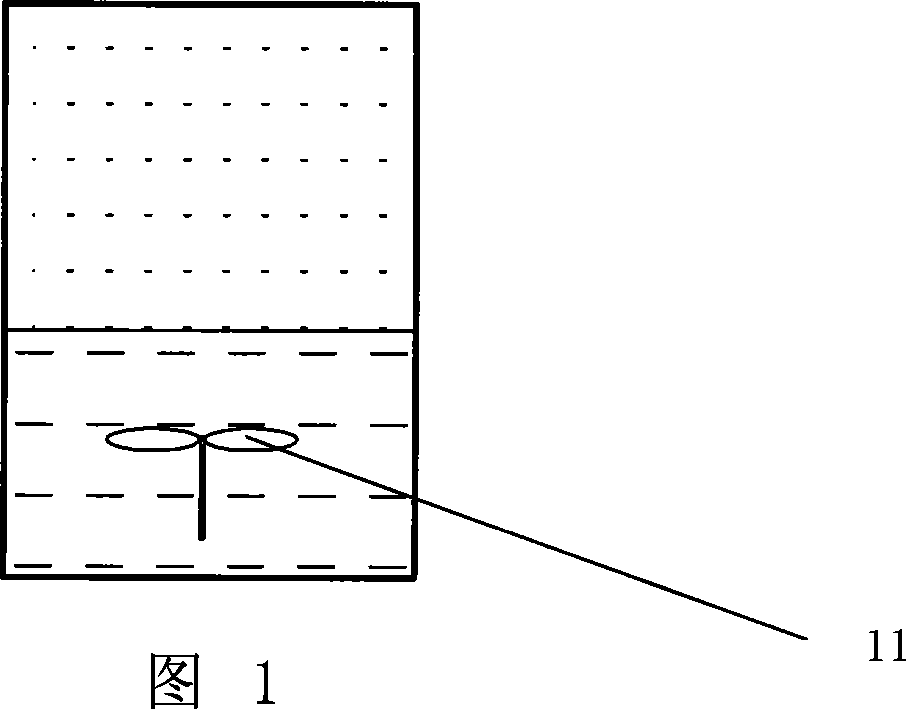

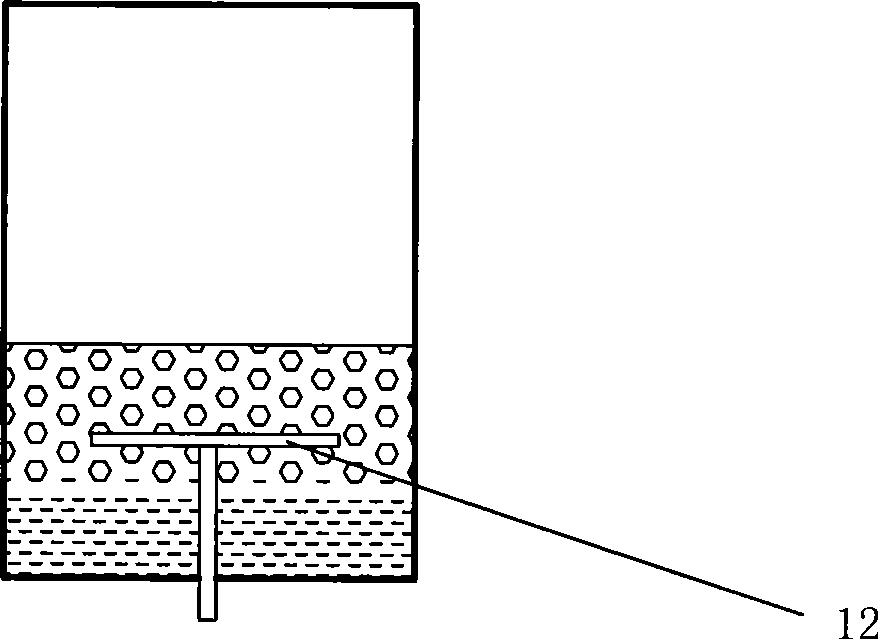

technical field [0001] The invention relates to a synthesis reactor of natural gas hydrate. Background technique [0002] The reactors used for hydrate synthesis in the world can be roughly divided into the following three types: [0003] ① Stirred reactor (see figure 1 ): When using, put water into the reactor first, and the gas enters through the bottom of the reactor. Under the action of the agitator, the gas and water are fully mixed to form natural gas hydrate. Using a shell-and-tube heat exchanger, the generated natural gas hydrate The latent heat released and the heat generated by rotating parts such as circulation pumps and stirrers in the reactor are carried away in time. However, this simple paddle-shaped stirring reactor has no obvious effect on increasing the gas-liquid interface contact area of hydrate synthesis, and is not suitable for industrial application. [0004] ② Bubble reactor (see figure 2 ): High-pressure gas is used to generate bubbles through...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10L3/10

Inventor 焦文玲宋汉成赵林波

Owner HARBIN INST OF TECH

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com