Treatment recovery method for monocrystalline silicon cutting waste liquor

A recovery method, single crystal silicon technology, applied in energy wastewater treatment, heating water/sewage treatment, silicon, etc., can solve the problem of not being found, and achieve the effect of low cost, good effect and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

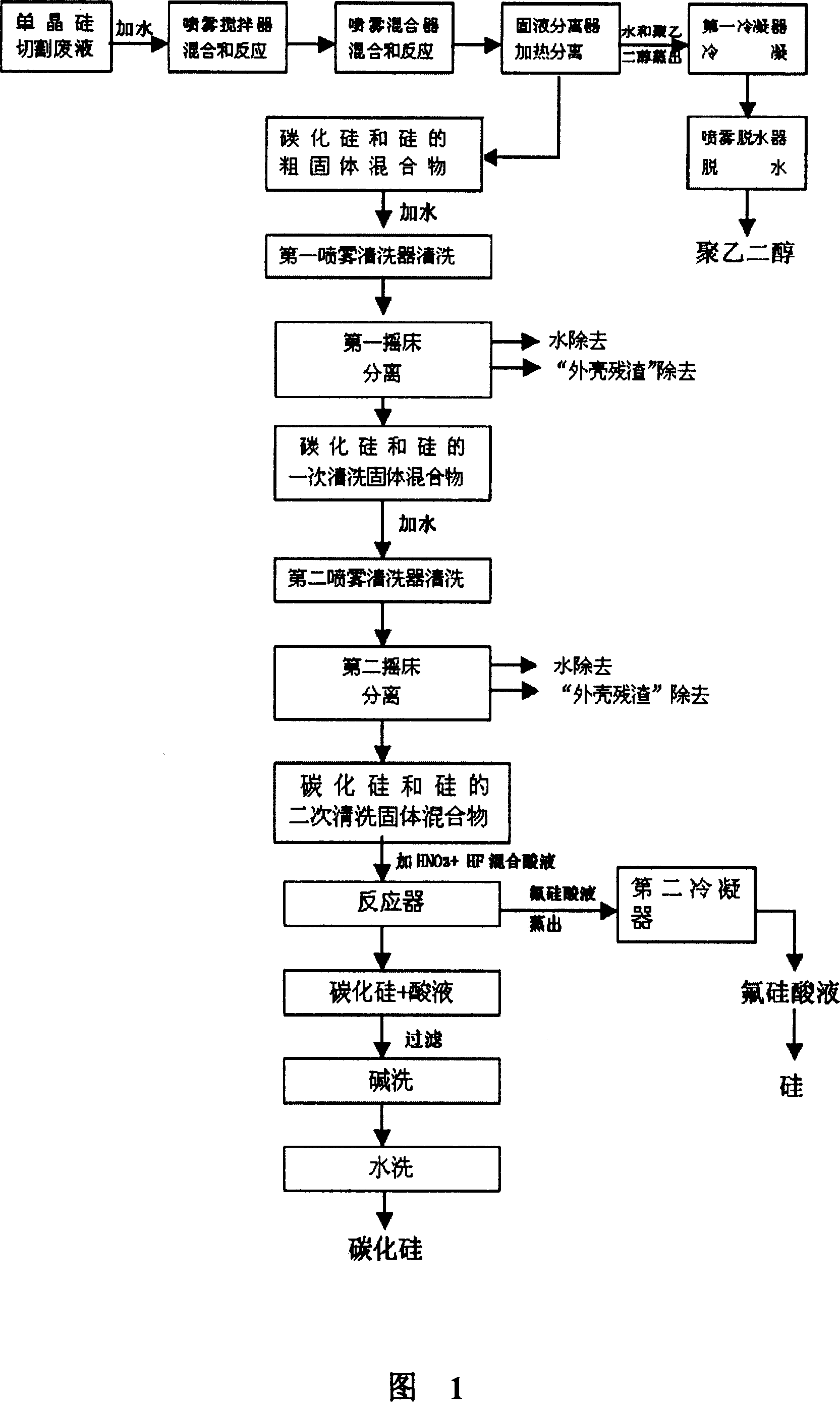

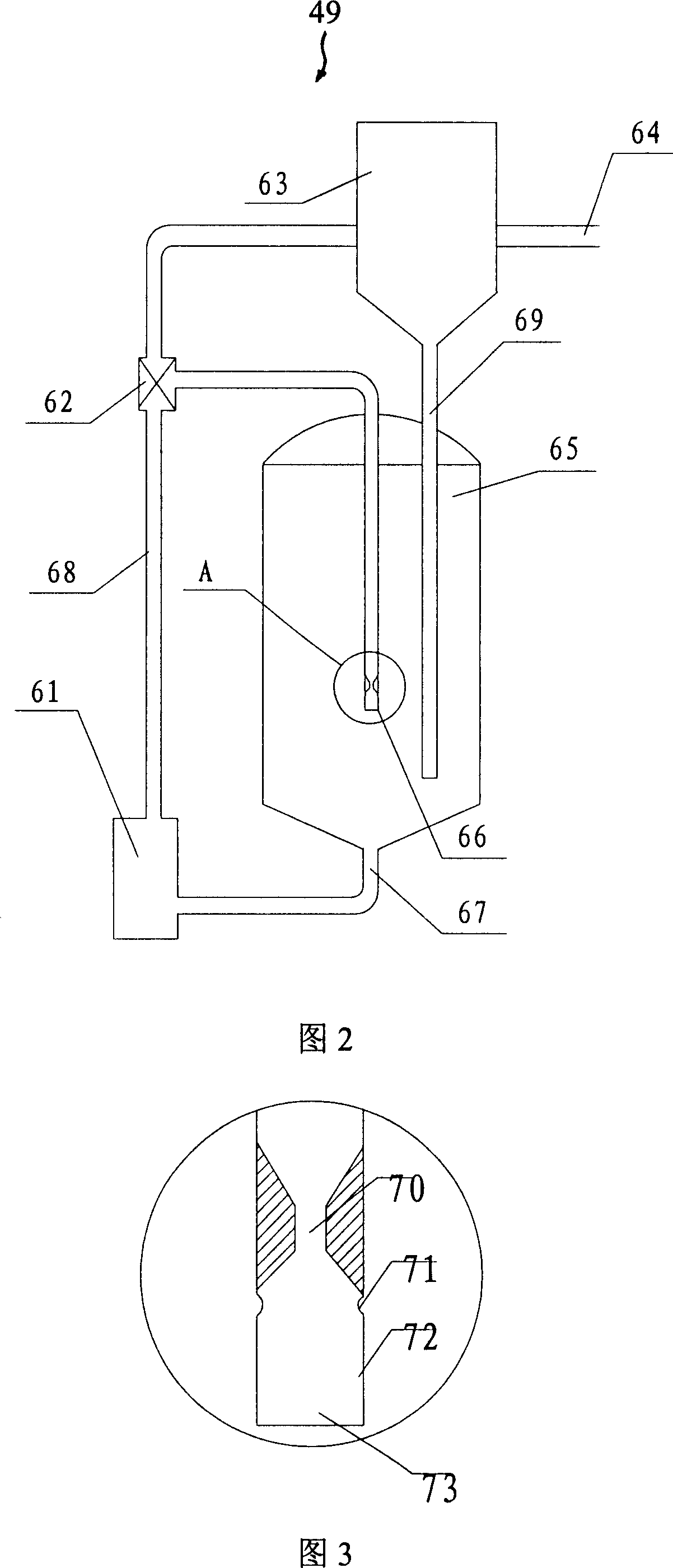

[0035] See Figures 1-6 of the accompanying drawings. 50 kg of monocrystalline silicon cutting waste liquid from which kerosene has been removed and 10 liters of dilute hydrochloric acid with a concentration of 0.01 mol enter the first mixing tank 65 of the spray mixer 49 through the first feeding tank 63 and its first feeding pipe 69 . The passage of the first three-way valve 62 and the first nozzle passage 66 is opened, and the passage with the first discharge pipe 64 is closed, and the first diaphragm pump 61 (pneumatic diaphragm pump model QBY-40, manufactured by Shanghai Changquan Pump Industry) is started. Co., Ltd.), the air pressure is 3kg / cm 2 , the mixture flows out from the first outlet 67 at the bottom of the first mixing kettle 65 through the first diaphragm pump 61, the first pipeline 68 and the first three-way valve 62, and the nozzle diameter entering the first spray channel 66 is a nozzle 70 of 3mm , the mixed material is quickly ejected from the first nozzle ...

Embodiment 2

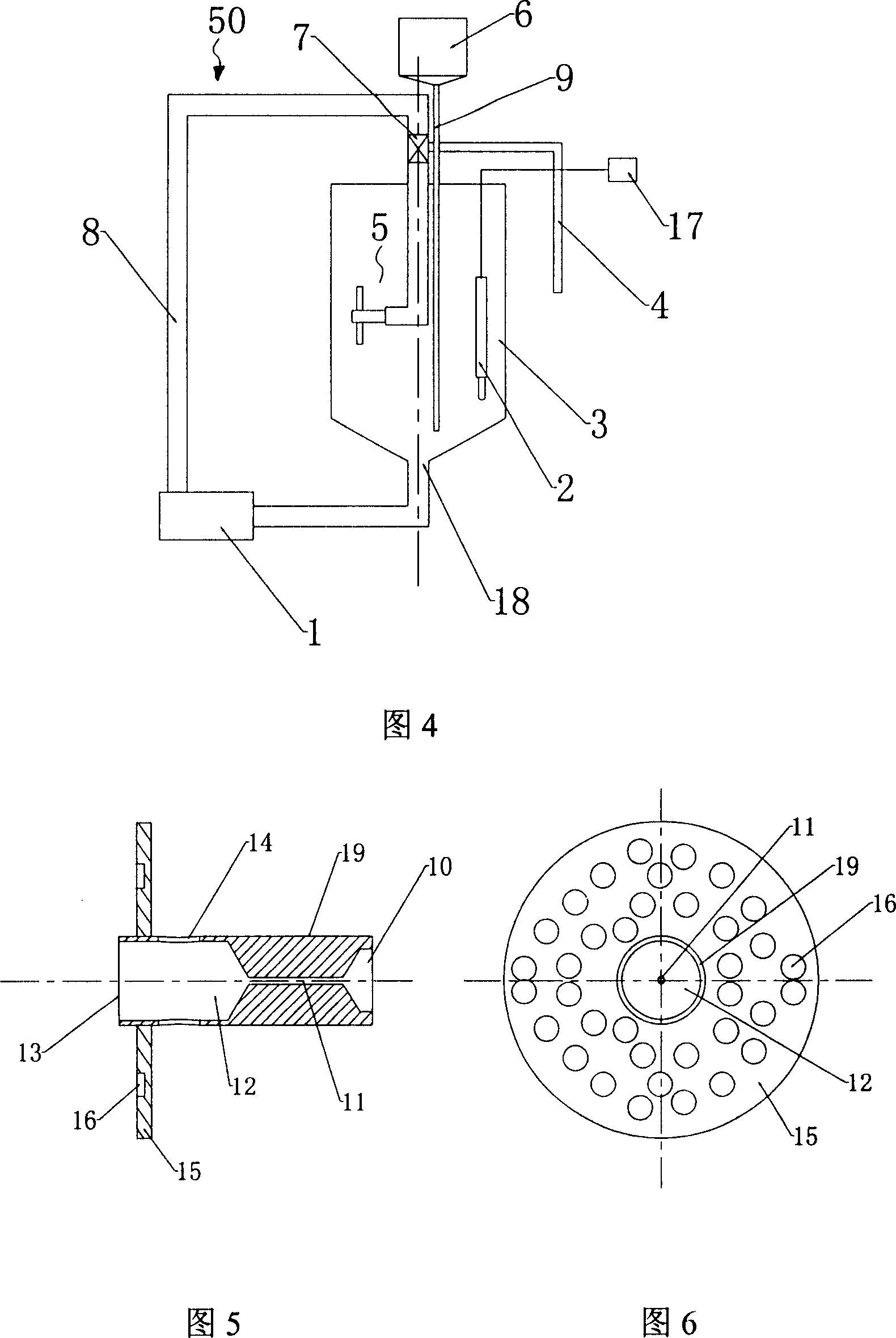

[0042] Add 50 kg of kerosene-free monocrystalline silicon cutting waste liquid and 15 liters of dilute hydrochloric acid with a concentration of 0.001 mol into the first mixing tank 65 of the spray agitator 49, and carry out repeated circulation of spray agitation and reaction for 20 minutes. The preliminary mixture obtained enters the spray mixer 50 for repeated cycle spray mixing and reaction for 20 minutes, the temperature rises to 50°C, the mixture enters the turbulent channel 11 in a turbulent state, the pump flow rate is 3 cubic meters per hour, and the diameter of the turbulent channel is 1.5mm , when the kinetic viscosity of the mixture is 40.6Pa·s, the Reynolds number is 9845. The secondary mixed material mixed by the spray mixer enters the solid-liquid separator 30, and the mixed material is heated by the electric heating plate of the two units whose temperature is maintained at 60 ° C. The water vapor and polyethylene glycol are steamed out together, and condensed to...

Embodiment 3

[0044] Add 50 kg of kerosene-removed monocrystalline silicon cutting waste liquid and 25 liters of dilute hydrochloric acid with a concentration of 0.0001 mol into the first mixing tank 65 of the spray mixer 49, and carry out repeated circulation of spray stirring and reaction for 30 minutes. The preliminary mixture obtained enters the spray mixer 50 for repeated cycle spray mixing and reaction for 10 minutes, the temperature rises to 40°C, the mixture enters the turbulent channel 11 in a turbulent state, the pump flow rate is 3 cubic meters per hour, and the diameter of the turbulent channel is 2.5mm , when the kinetic viscosity of the mixture is 28.4Pa·s, the Reynolds number is 3040. The secondary mixed material mixed by the spray mixer enters the solid-liquid separator 30, and the mixed material is heated by the electric heating plate of the two units whose temperature is maintained at 80 ° C. The water vapor and polyethylene glycol are steamed out together, and condensed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com