Processing technique for oil-contaminated water and equipment thereof

A technology for treating equipment and oily sewage, applied in water/sewage treatment, flotation water/sewage treatment, neutralized water/sewage treatment, etc. The effect of water pollution, low operating cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

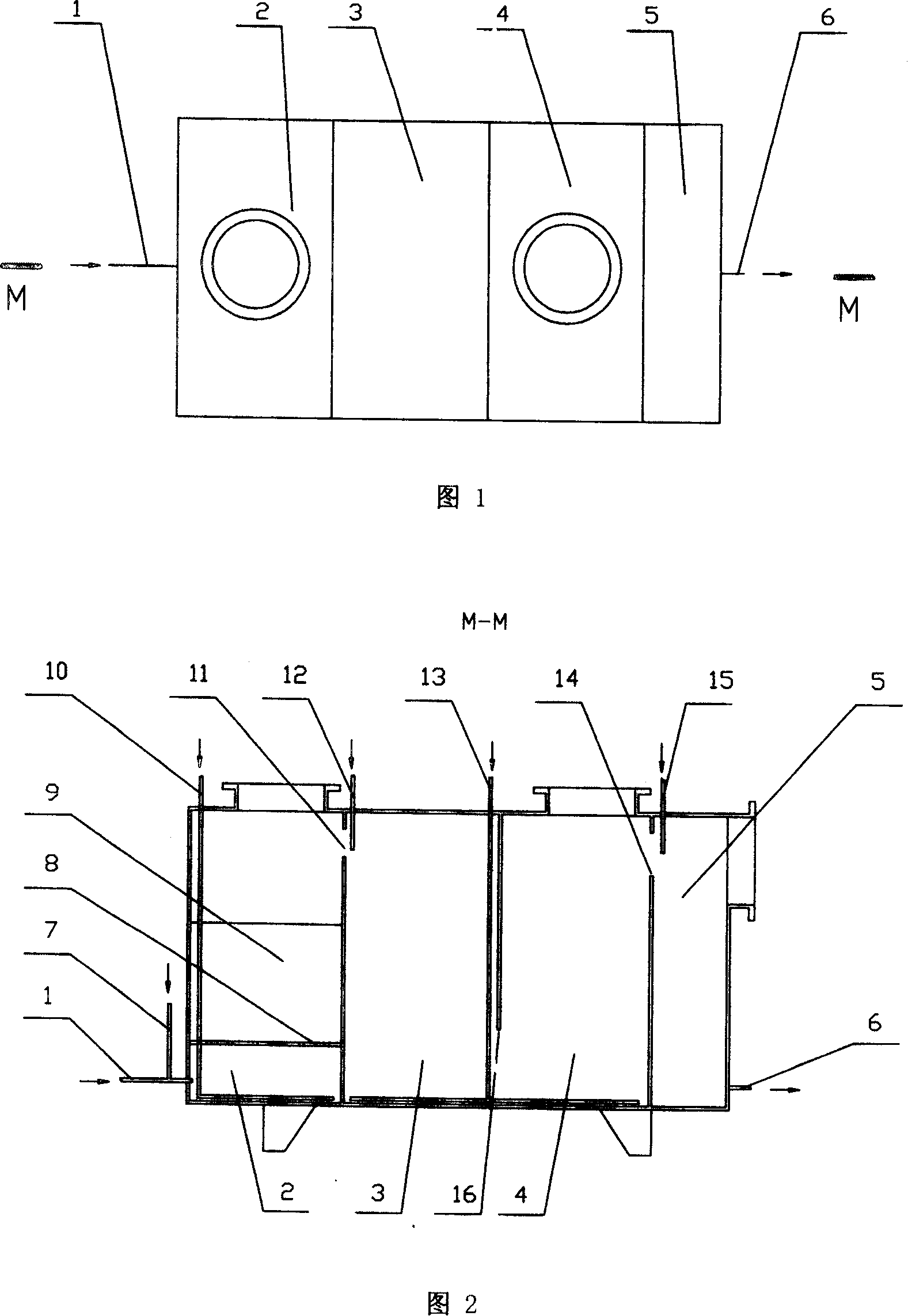

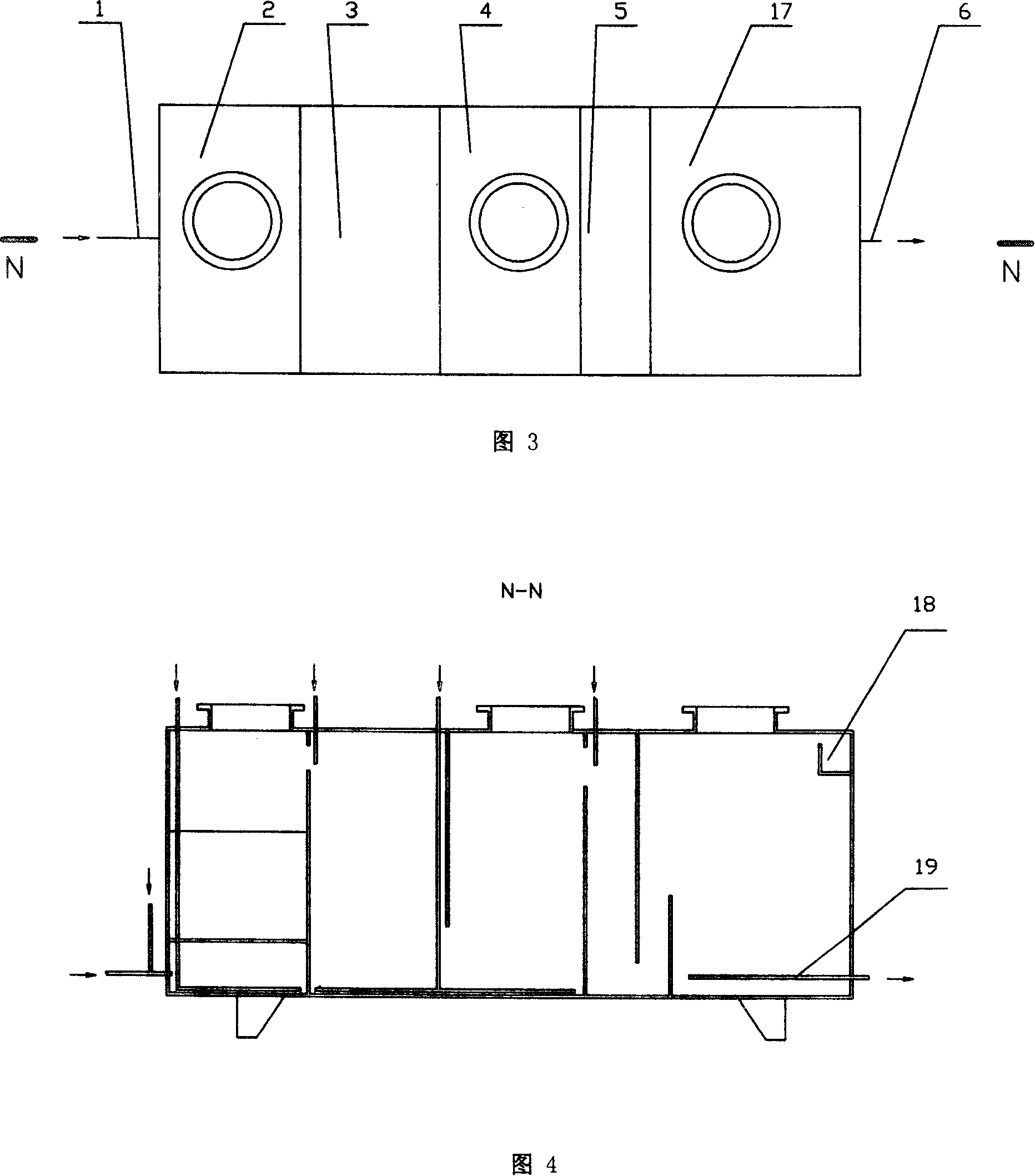

Image

Examples

Embodiment 1

[0034] It includes the following steps:

[0035] 1), carry out micro-electrolysis reaction to sewage, inject sulfuric acid into the sewage in the container, when the pH value of sewage reaches 4.0, stop injecting sulfuric acid, keep the reaction time of sewage in the container to be 45 minutes;

[0036] 2), carry out Fenton reaction to the sewage in the previous step, inject composite oxidant into the sewage in the container, the composite oxidant is hydrogen peroxide and potassium dichromate, the mass ratio of the two is 1000: 1, and the volume ratio of composite oxidant to sewage is 0.5 %, the reaction time is 210 minutes;

[0037] 3), then input the effluent from the previous step into the precipitator, inject sodium hydroxide solution into the precipitator, when the pH value of the water in the precipitator is adjusted to 7.5, stop injecting the sodium hydroxide solution, and settle for 2 hours;

[0038] 4) The water output from the settler is input into the clean water t...

Embodiment 2

[0040] It includes the following steps:

[0041] 1), carry out micro-electrolysis reaction to sewage, inject hydrochloric acid into the sewage in the container, when the pH value of sewage reaches 5.5, stop injecting hydrochloric acid, keep the reaction time of sewage in the container to be 50 minutes;

[0042] 2), carry out Fenton reaction to the sewage in the previous step, inject the composite oxidant into the sewage in the container, the composite oxidant is hydrogen peroxide and potassium dichromate, the mass ratio of the two is 1500: 1, and the volume ratio of the composite oxidant to sewage is 0.4 %, the reaction time is 165 minutes;

[0043] 3), then input the effluent from the previous step into the precipitator, inject calcium hydroxide solution into the precipitator, adjust the pH value of the water in the precipitator to 8, stop injecting the calcium hydroxide solution, and settle for 2 hours;

[0044] 4) The water output from the settler is input into the clean w...

Embodiment 3

[0046] It includes the following steps:

[0047] 1) Perform micro-electrolysis reaction on the sewage, inject sulfuric acid into the sewage in the container, stop injecting sulfuric acid when the pH value of the sewage reaches 4.0~7.0, and keep the reaction time of the sewage in the container for 55 minutes;

[0048] 2), carry out Fenton reaction to the sewage in the previous step, inject composite oxidant into the sewage in the container, composite oxidant is hydrogen peroxide and potassium dichromate, the mass ratio of the two is 2000: 1, composite oxidant and sewage volume ratio are 0.3 %, the reaction time is 120 minutes;

[0049] 3), then input the effluent from the previous step into the precipitator, inject calcium hydroxide solution into the precipitator, when the pH value of the water in the precipitator is adjusted to 8.5, stop injecting the calcium hydroxide solution, and settle for 2 hours;

[0050] 4) The water output from the settler is input into the clean water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com