Waste gas heat reclaiming device and stenter setting machine possessing same

A technology of waste gas heat recovery and tenter setting machine, which is applied in indirect heat exchangers, fabric elongation, heat exchanger types, etc. Faster, less hazard, and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

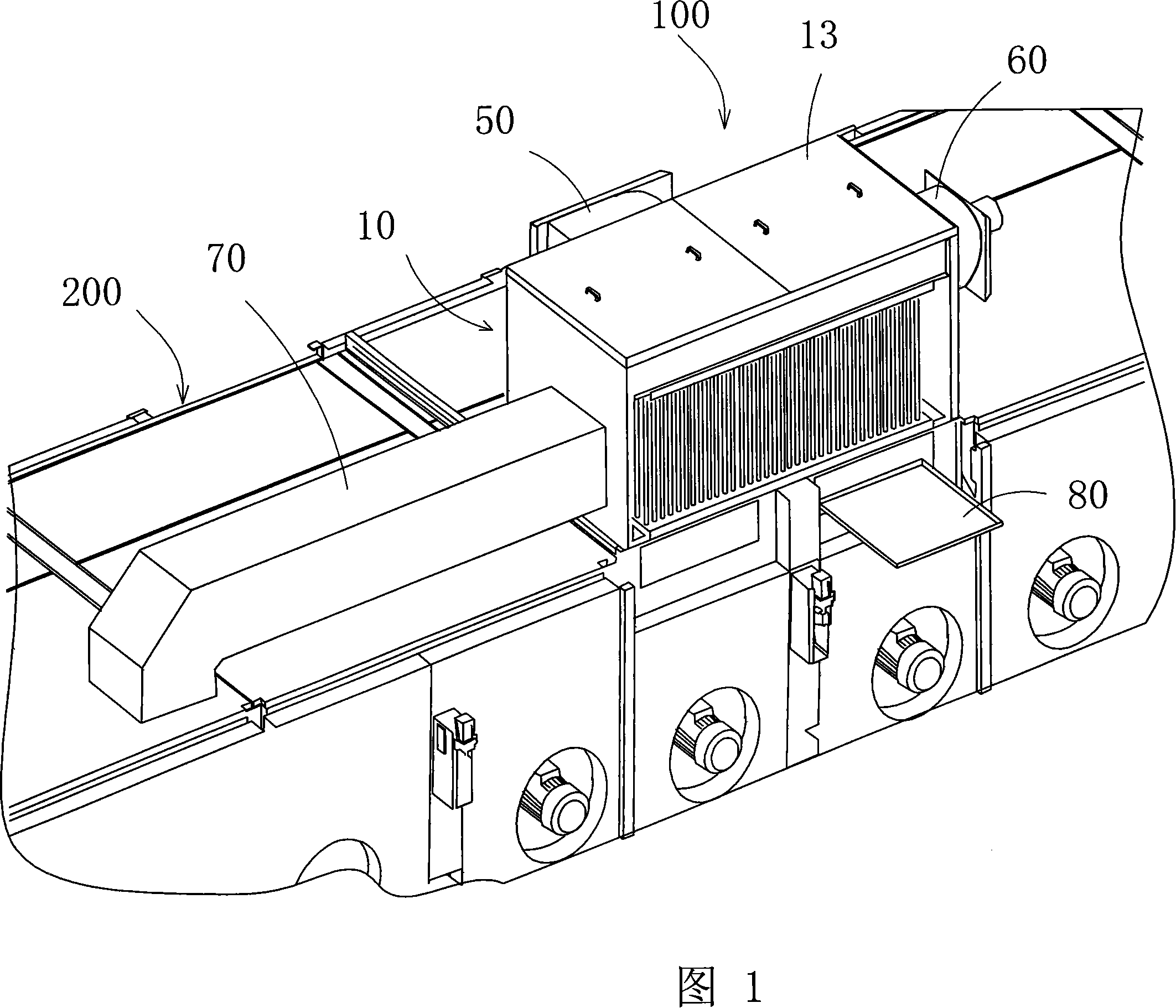

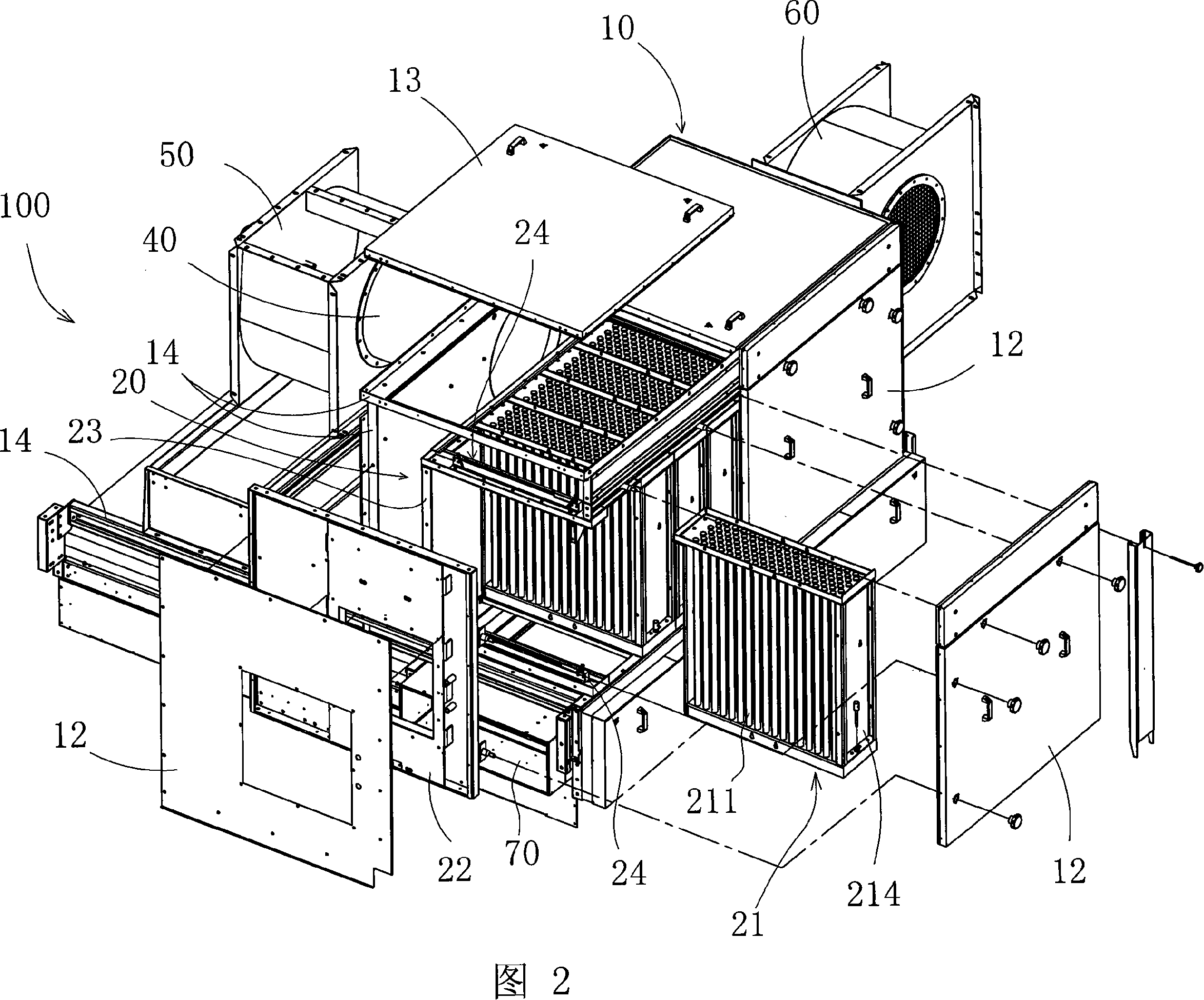

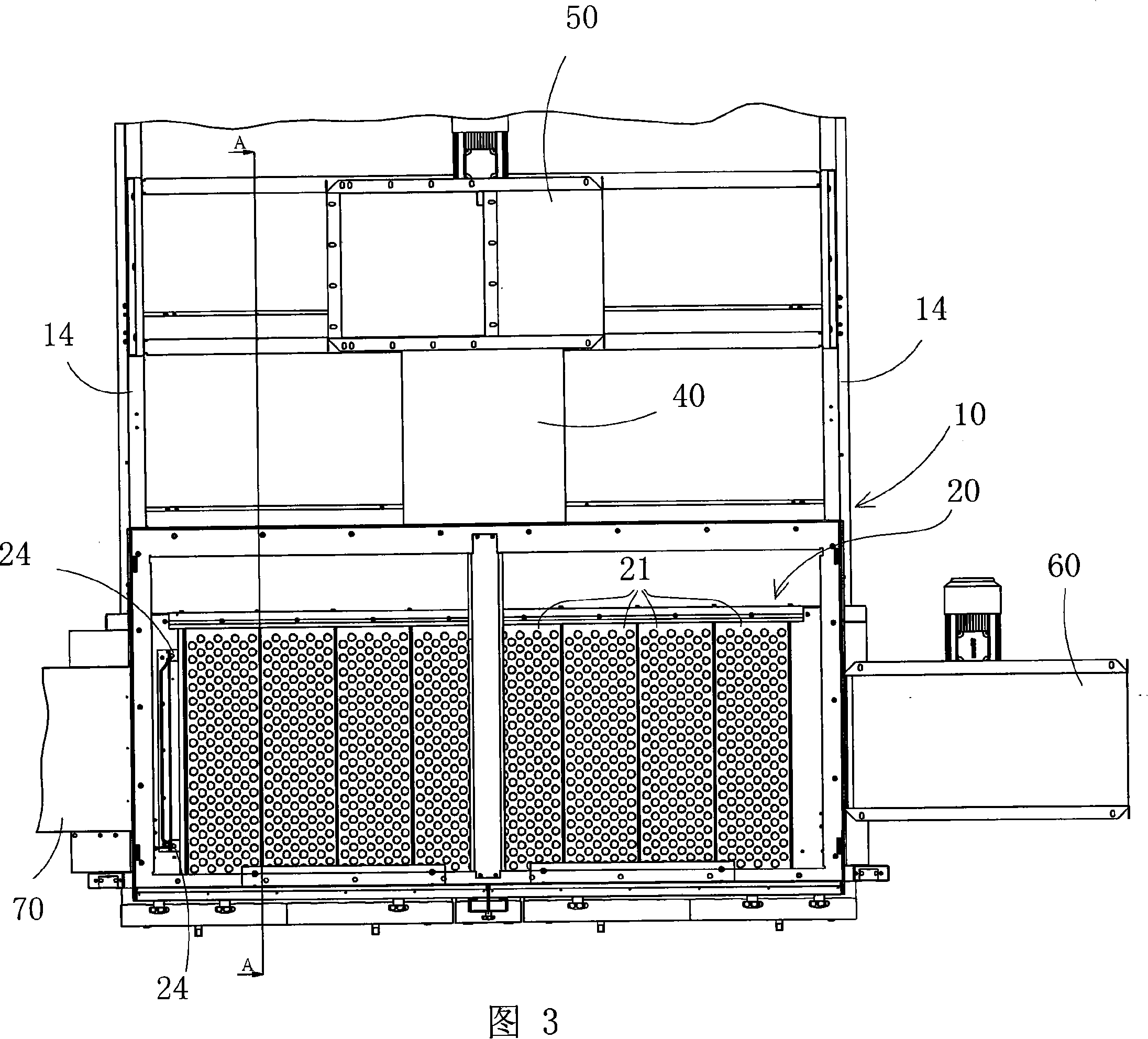

[0028] Referring to Figs. 1 to 4, Fig. 1 is a three-dimensional schematic view of the waste gas heat recovery device of the present invention installed on the top of the oven of the stenter setting machine. In order to facilitate the viewing of the internal heat exchange tube 211, the Front cover plate 12. The waste gas heat recovery device of the present invention has a heat recovery box 10, the heat recovery box 10 is sealed and connected to the box bracket 14 by the surrounding outer sealing plate 12 and the openable upper cover 13, and passes through the box bracket 14 It is formed by sealingly connected to the top of the oven. The rear of the box is connected with an exhaust pipe 40, and the exhaust pipe is connected with an exhaust fan 50. It is through this exhaust fan that the final waste gas is discharged to the outside. The left side of the body is connected with a fresh air blower 60, which sends fresh air into the heat recovery box for heat exchange and obtains hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com