Method for inhibiting metallic corrosion

A kind of metal corrosion inhibition, metal technology, applied in the direction of metal material coating process, etc., can solve the problems such as environmental adverse effects, and achieve the effect of slowing down metal corrosion and changing corrosion reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

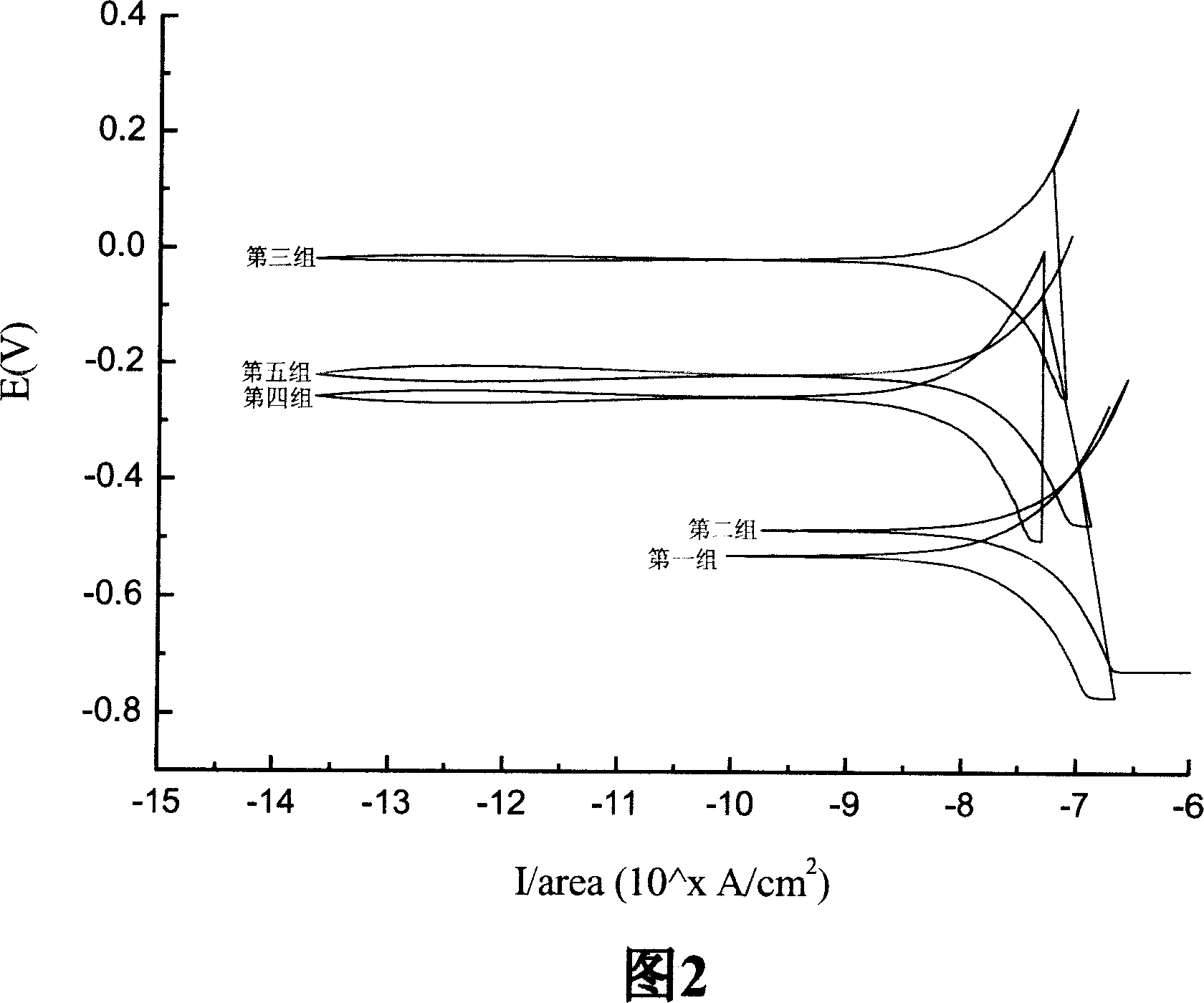

[0016] The metal corrosion suppression method disclosed in the present invention is applied to a metal-containing substrate, the surface of which is in contact with the reaction solution, and the method of contacting the surface of the metal-containing substrate with the reaction solution can be that the metal-containing substrate is soaked in the reaction solution, Or spray the reaction solution on the metal-containing substrate. As shown in Figure 1, it is the implementation flowchart of the preferred embodiment of the present invention, first mix ozone in reaction solution (step 110); Form metal oxide protective layer on the substrate surface (step 120) containing metal; Addition to the reaction solution (step 130). In the embodiment of the present invention, the step of adding ozone to the reaction solution may be dissolved in the reaction solution by adding a solution dissolved in ozone to the reaction solution, or directly adding ozone gas. The reaction solution include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com