Durable high performance composite conductive fibre and manufacturing method

A composite conductive, high-performance technology, applied in conductive/antistatic filament manufacturing, fiber processing, textiles and papermaking, etc., can solve problems such as low conductivity, large amount of conductive fibers, and inability to meet high-level purification requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

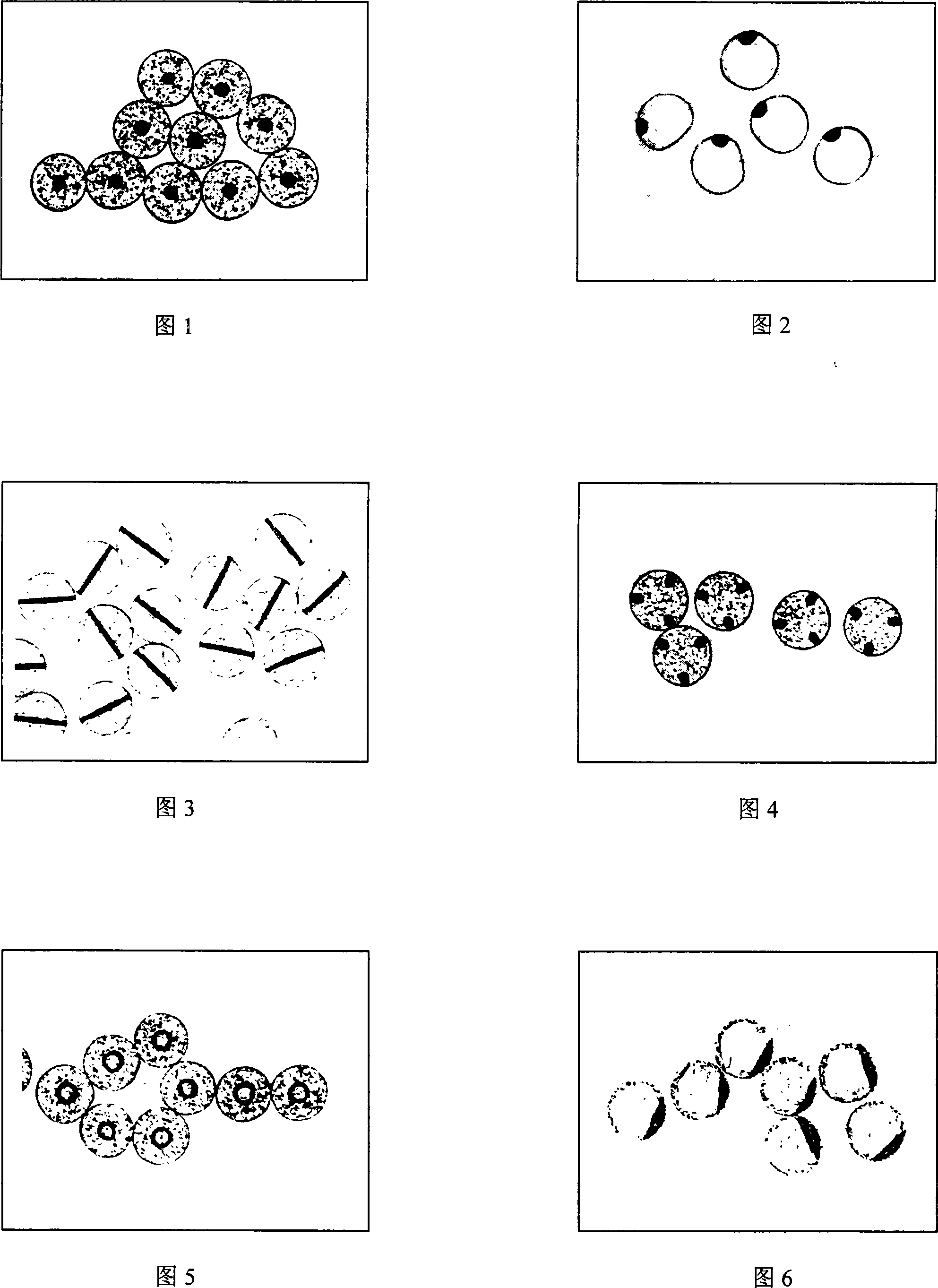

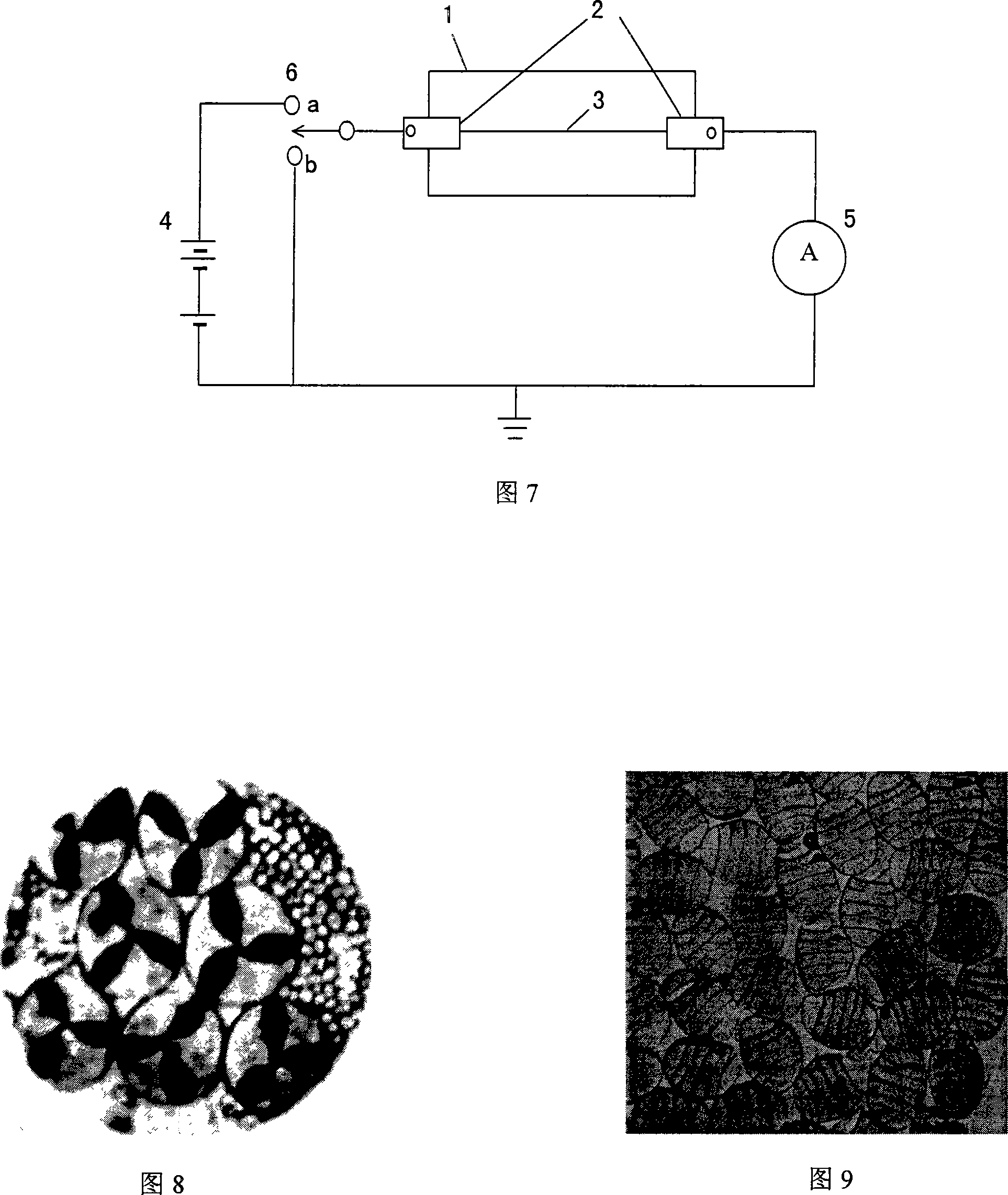

[0034] Add 20 parts of high-conductivity carbon black with a particle size of 1 μ and 20 parts of polyethylene vinyl acetate into a high-speed mixer, perform high-speed mixing at a temperature of 105° C., cool down after 30 minutes and pulverize into granules. Add the granular blend and 60 parts of polyester powder into a high-speed mixer, heat mix at 150°C for 15 minutes, and then cold mix for 15 minutes to discharge the material into the hopper of the twin-screw extruder, heat at 280°C Down extrusion granulation into conductive layer particles, after drying as A component. Dried polyester chips are used as component B.

[0035] A component and B component are melted and extruded in their respective screw extruders, enter their respective metering pumps, and are metered according to the composite ratio of A / B=30 / 70, and then enter into the three-lobed composite spinning of A component In the assembly, in the composite spinning assembly, components A and B are sprayed out fro...

Embodiment 2

[0038] The distribution ratio and composite ratio of A and B components and the spinning conditions are the same as in Example 1, except that the winding speed is 1500m / min, and the double-zone stretching machine is used at 85°C / 180°C, stretched by 3.0 times, and the stretching speed is 600m Stretching and winding under / min, the cross-section of the composite conductive fiber manufactured is the same as example 1, the linear density of the conductive fiber is 23.7dtex / 2F, the breaking strength is 3.3CN / dtex, the elongation at break is 36%, and the resistivity is 7.3× 10 4 Ω / cm.

Embodiment 3

[0040] The distribution ratio and composite ratio of A and B groups and the spinning conditions are the same as in Example 1, but the as-spun yarn spun by one-step spinning and drawing process is oiled on the oil tanker and then enters GR1 and GR2 hot rollers for hot drawing, GR1 The temperature was set at 88°C, the temperature of GR2 was set at 123°C, and the speed of the winder was 4050m / min. The cross-section of the composite conductive fiber is the same as example 1, the linear density of the conductive fiber is 22.6dtex / 2F, the breaking strength is 3.1CN / dtex, the elongation at break is 46%, and the resistivity is 5.7×10 4 Ω / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com