Thruster of brake

A technology of pushers and brakes, applied in the direction of brake actuators, etc., can solve the problems of increasing maintenance and repair workload, affecting service life, aging of seals, etc., to reduce maintenance and repair workload, prolong service life and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

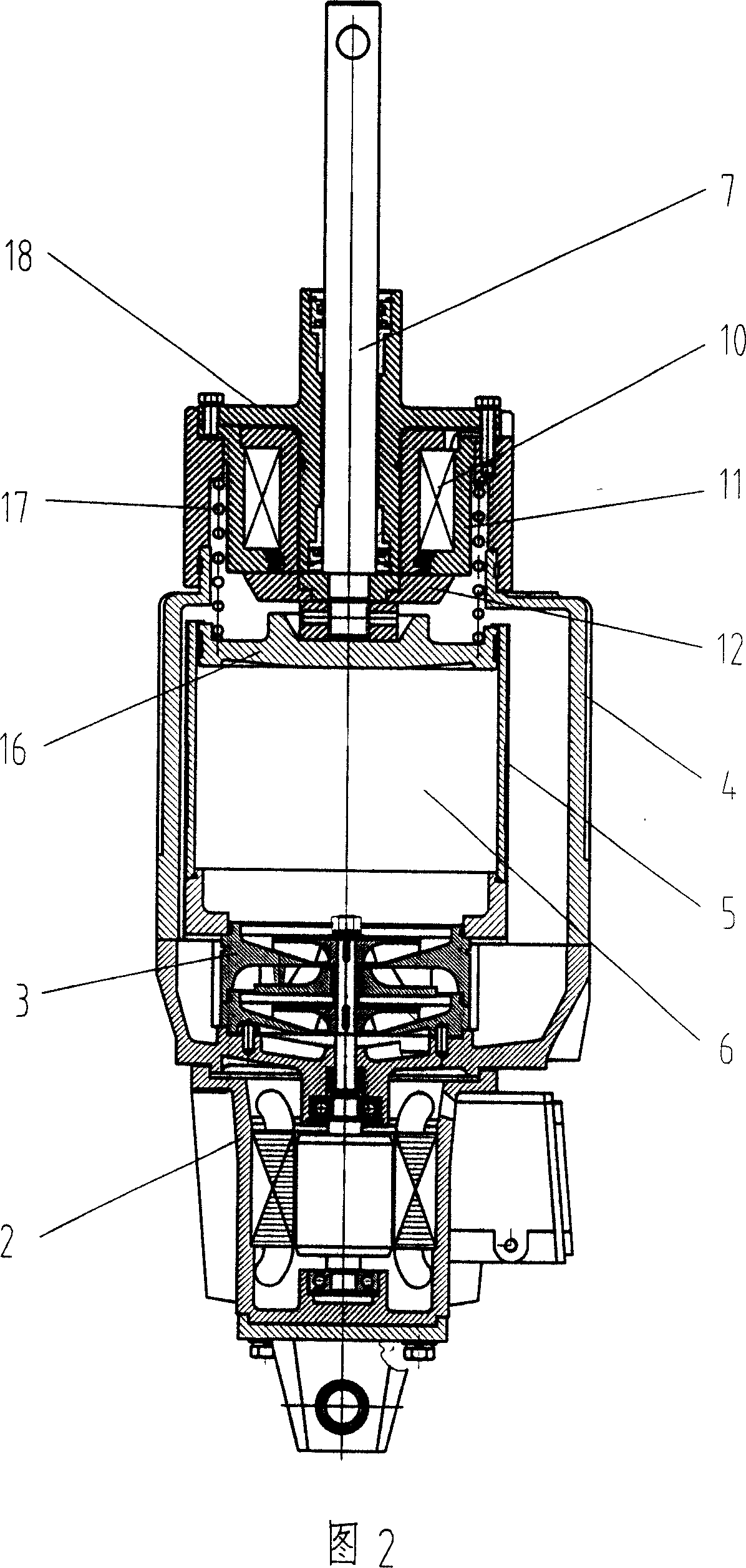

[0017] As shown in Fig. 1 and Fig. 2, the brake is provided with a driving device 2 and a liquid pump 3 driven by the driving device, a liquid storage tank 4 and a hydraulic cylinder 5, the inlet of the liquid pump 3 communicates with the liquid storage tank 4, and the liquid pump 3 The outlet of the hydraulic cylinder communicates with the driving liquid cavity 6 of the hydraulic cylinder 5. The piston rod of the hydraulic cylinder, that is, the push rod 7, is used to be hingedly connected with the driving member 9 of the braking part 8, and an electromagnetic device 10 is provided to keep the braking part 8 in a working state. .

[0018] The driving device 2 can be of different types. As shown in FIG. 2 , the driving device 2 adopts a motor, and the liquid pump 3 is a centrifugal pump. As shown in FIG. 3 , the driving device 2 adopts an electromagnet, and the liquid pump 3 is a plunger pump integrated with the electromagnet.

[0019] There are many configurations of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com