Environment-friendly type on-press-coating ink-jet CTP offset master, pigment ink and preparation method thereof

A pigment ink and pigment technology, applied in the field of environment-friendly bare plate inkjet CTP offset printing plate, can solve the problems of unfavorable environmental protection, polluting the environment, affecting the quality of plate making, etc., and achieve the effect of reducing printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

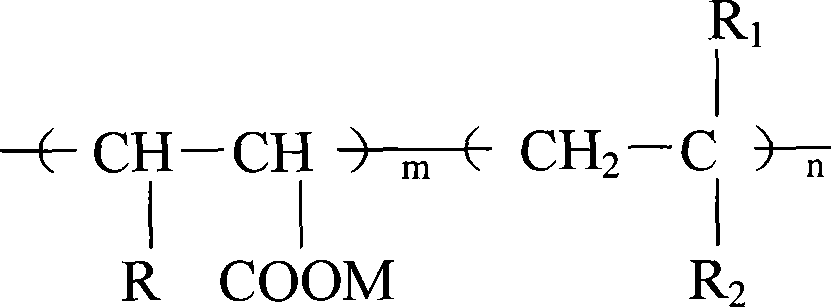

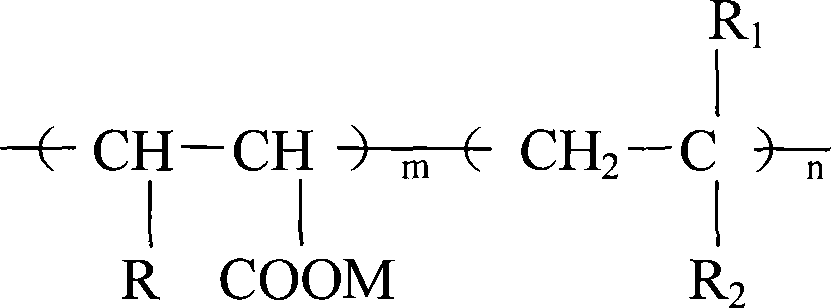

Method used

Image

Examples

Embodiment 1

[0050] 12 grams of 50% acrylic acid-butyl acrylate copolymer emulsion (M=15000±200) with a molar ratio of acrylic acid: butyl acrylate = 1: 1.2, in which 4g of pigment black, 2g of OP-10 1% aqueous solution, 16g of ethyl Diol, 10g polyethylene glycol, 2g hexamethylol melamine resin, 30g deionized water, stir with a mixer at 500 rpm for 30 minutes, then stir at a high speed with an emulsifier at 2000 rpm for 30 minutes, sand Grinding in a mill for 80 minutes, finally adjusting the pH value to 9, and filtering through a 0.5-1 μm microporous membrane to obtain black pigment ink. The physical properties of this ink at 20°C are as follows:

[0051] Surface tension 35mN / m,

[0052] Viscosity 3.5cp,

[0053] Particle size d=100nm,

[0054] Conductivity 1000US,

[0055] pH=9.0.

Embodiment 2

[0057] Add 8g of 50% styrene-ethyl acrylate copolymer emulsion M=(10000±150), molar ratio: styrene: ethyl acrylate=1.5:1, then add 7g of pigment black, 1g of OP-7 1% aqueous solution, 20g Ethylene glycol, 15g n-butanol, 2g hexamethylol melamine resin, 24g deionized water, stir for 30 minutes with a stirrer at 500 rev / min, then stir at a high speed for 60 minutes with an emulsifier at 10000 rev / min, sand Mill for 120 minutes, finally adjust the pH value to 8, filter with a 0.5-1μm microporous membrane to obtain black pigment ink, and the physical properties of this ink at 20°C are as follows:

[0058] Surface tension 40mN / m,

[0059] Viscosity 4.0cp,

[0060] Particle size d=130nm,

[0061] Conductivity 1200US,

[0062] pH = 8.0.

Embodiment 3

[0064] With 17g 50% maleic anhydride-methyl methacrylate copolymer (M=10000 ± 150), molar ratio: maleic anhydride: methyl methacrylate=1: 1, then add 8g pigment black, 2g OP-10 10% aqueous solution, 10g ethylene glycol, 15g polyethylene glycol, 1g hexamethylolmelamine resin, 32g deionized water, stir for 30 minutes with a stirrer at 500 rpm, and then use 10000 rpm The separate emulsifier is stirred at high speed for 60 minutes, and the sand mill is crushed for 90 minutes. Finally, the pH value is adjusted to 9, and the black pigment ink is obtained by filtering with a microporous membrane of 0.5-1 μm. The physical properties of this ink at 20 ° C are as follows:

[0065] Surface tension 35mN / m,

[0066] Viscosity 3.5cp,

[0067] Particle size d=105nm,

[0068] Conductivity 900US,

[0069] pH=9.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com