Diamond anvil for electrical quantity in-situ measurement and its production method

A diamond-to-anvil, in-situ measurement technology, applied in measurement devices, scientific instruments, material analysis by electromagnetic means, etc., can solve the problems of difficult temperature increase, large temperature gradient, temperature loss, etc., to prevent heat loss. , measurement accuracy guarantee, the effect of reducing the temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 Illustrates the overall structure of the present invention in conjunction with the accompanying drawings

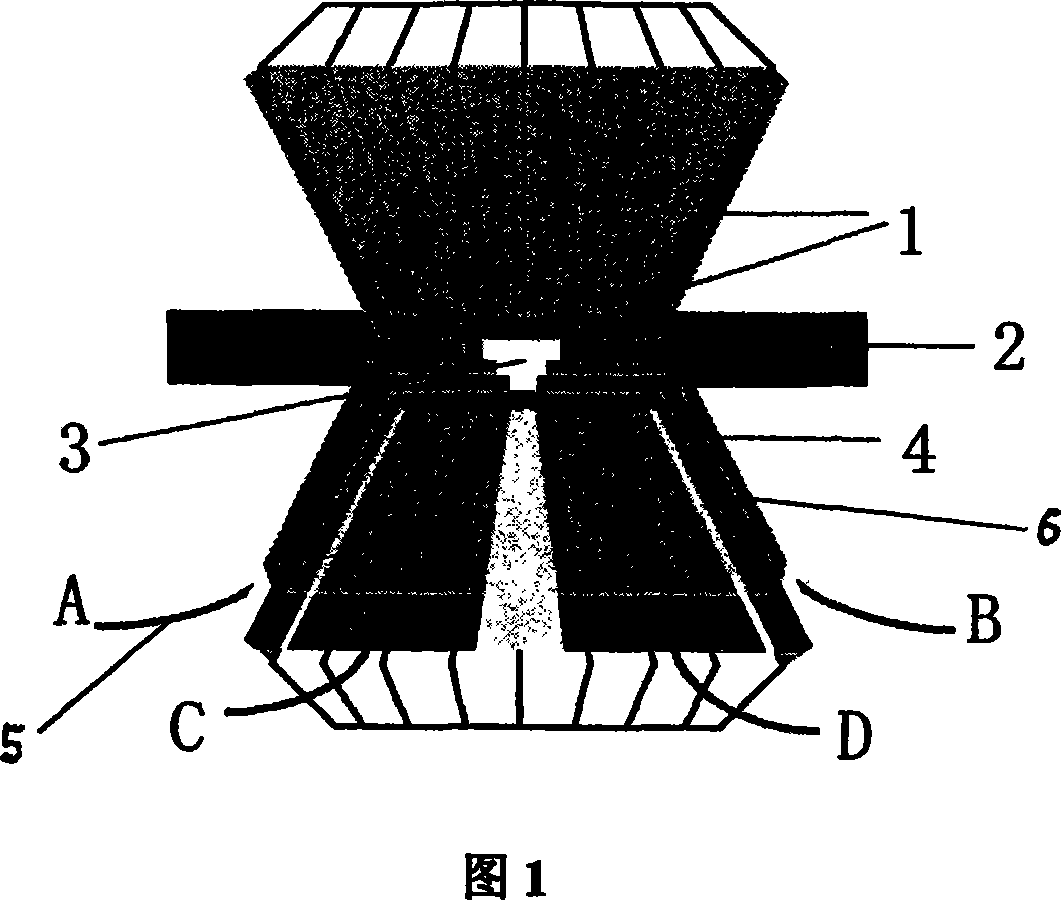

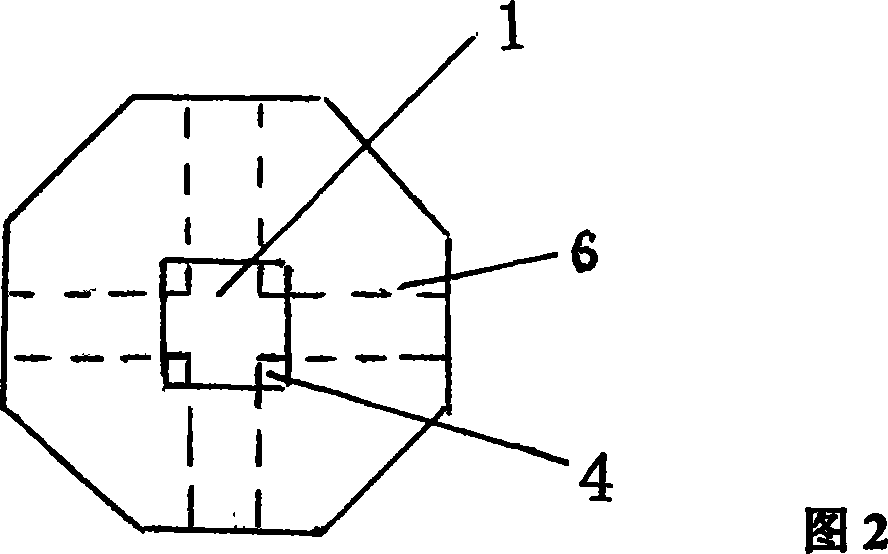

[0029] Refer to Fig. 1 and Fig. 2 for the overall structure of a diamond anvil of the present invention.

[0030] In Figure 1 and Figure 2, 1 is the alumina heat insulation layer, 2 is the sealing gasket, 3 is the sample chamber, 4 is the electrode, 5 is the electrode lead, there are four A, B, C, D, 6 is the protective layer, It is made of alumina material.

[0031] In FIG. 1 , two diamond anvil surfaces face each other to form a diamond counter-anvil. There is a sealing gasket 2 between the two diamond anvil surfaces, so that the space in the middle forms a sample cavity 3 . The upper diamond anvil is only deposited with an aluminum oxide heat insulating layer 1 on its anvil surface and side surfaces, the lower diamond anvil has four or two electrodes 4, and electrode leads 5 are welded at the ends of the electrodes 4 on the side of the diamond anvi...

Embodiment 2

[0035] Embodiment 2 The fabrication of the diamond pair anvil for in-situ measurement of electrical quantities of the present invention

[0036] Step 1: Soak two diamond anvils in a mixture of acetone and alcohol for 20 minutes to remove surface stains, and rinse with deionized water after taking them out.

[0037] Step 2: After drying, put the diamond anvil into the vacuum chamber, and use the magnetron sputtering method to deposit an aluminum oxide film on the surface of the two diamonds as a heat insulating material, that is, form an aluminum oxide heat insulating layer 1 . In order to increase the adhesion between the diamond and the film, the substrate is kept at 300 degrees Celsius during the sputtering process, and metal aluminum is used as the target material during the sputtering process, and oxygen and argon with a flow ratio of 30:2.4 are used as the working gas , the pressure in the vacuum chamber is always kept at 1Pa during the coating process.

[0038] The abov...

Embodiment 3

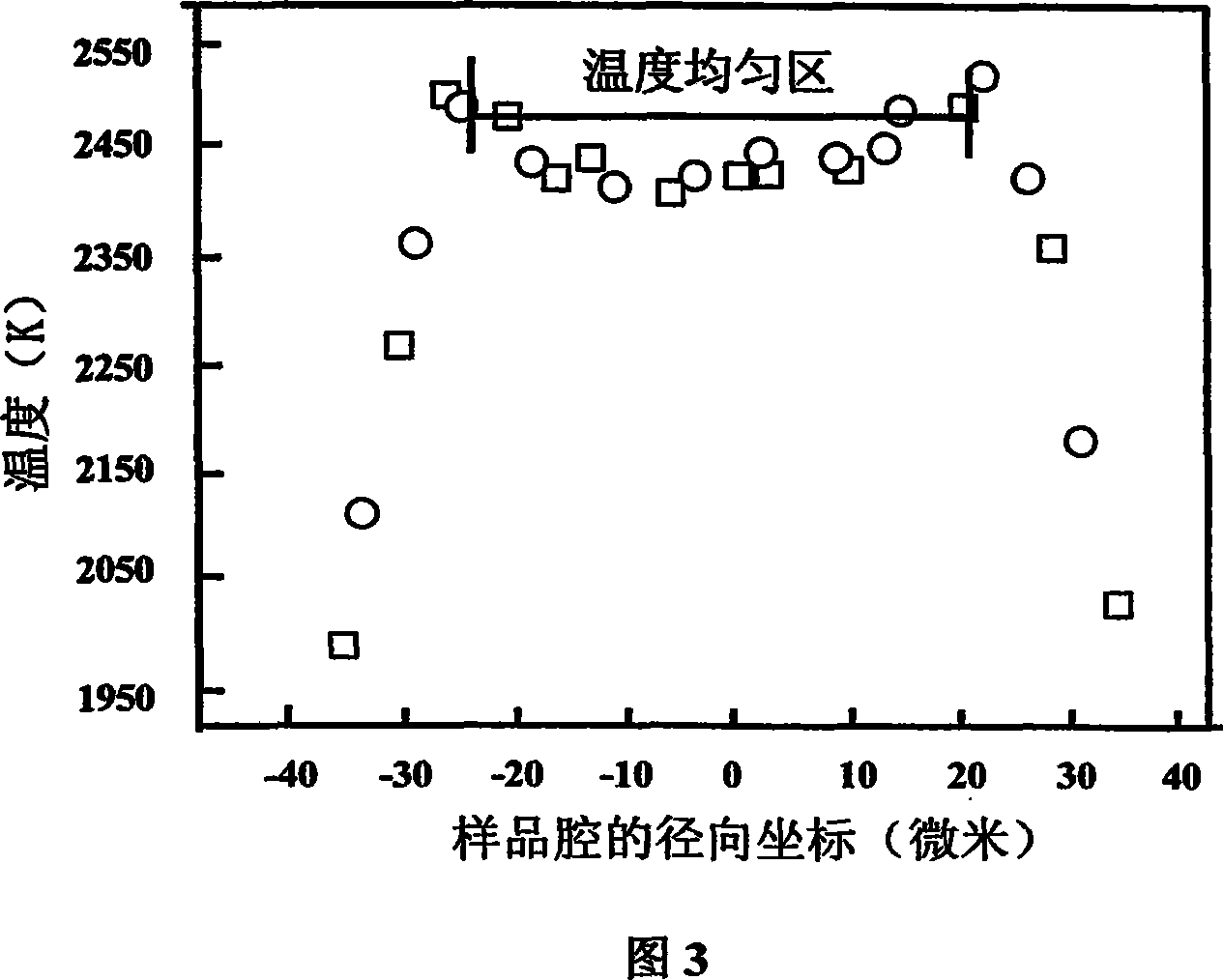

[0051] Example 3 An example of the thermal insulation effect of alumina—the difference between the presence and absence of the thermal insulation layer 1 of alumina.

[0052] The olivine sample was selected to test the thermal insulation performance of diamond on the anvil. The results obtained are shown in Figure 3 and Figure 4. Fig. 3 is the radial temperature distribution of the sample chamber measured without any heat insulating layer, and Fig. 4 is the radial temperature distribution of the sample chamber when a 3 micron alumina heat insulating layer 1 is introduced. The maximum temperature difference in the temperature uniform area (the area marked by the horizontal line in the figure) is greater than 120 degrees without the alumina heat insulation layer, and the maximum temperature difference is less than 50 degrees with the alumina heat insulation layer 1, and the range of uniform temperature is from without alumina heat insulation ~45 microns in layers, increasing to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com