Integral sealing electric obstructing instrument

A technology of overall sealing and barriers, applied in roads, restricted traffic, roads, etc., can solve the problems of surrounding environmental pollution, complex structure, large road area occupied by construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

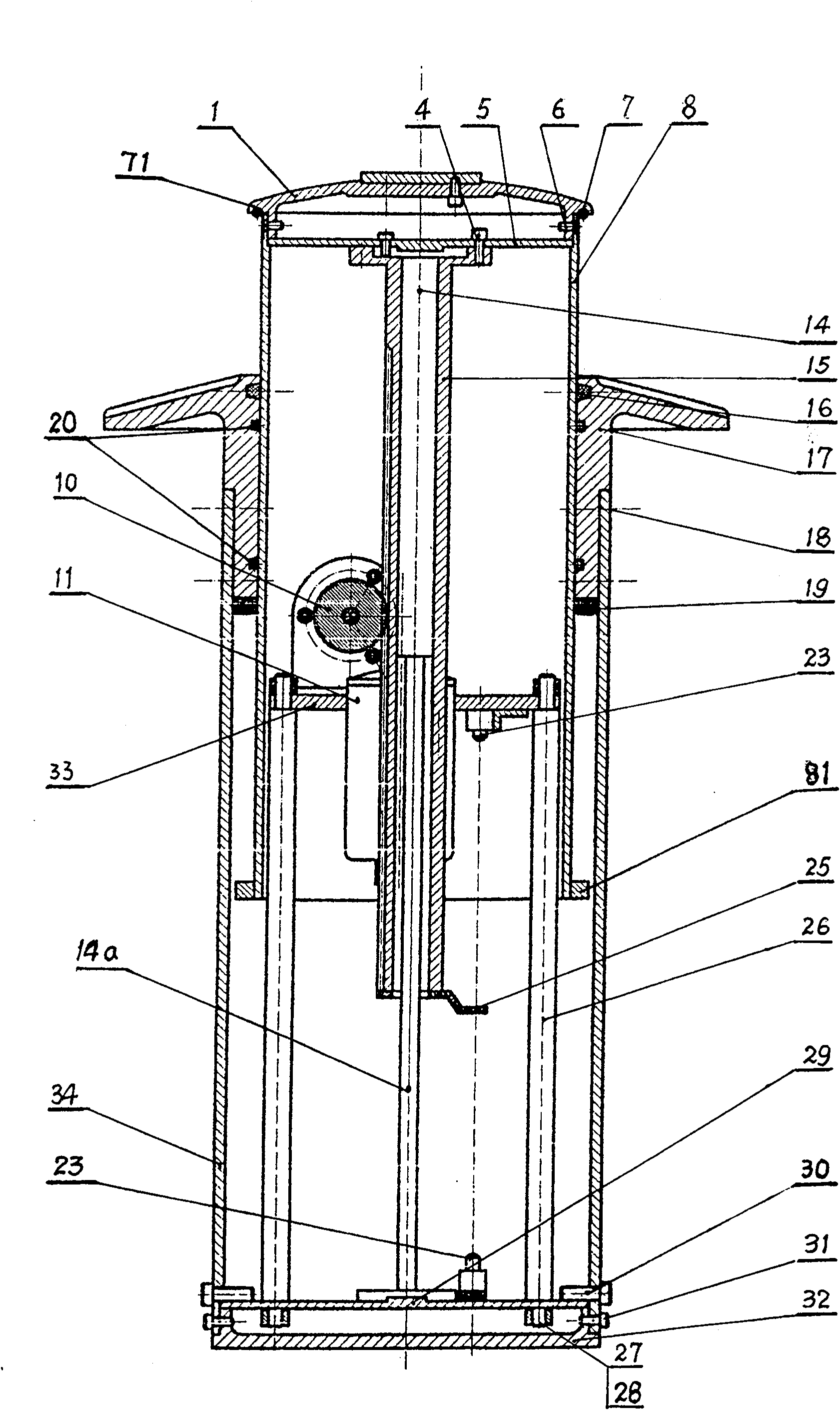

[0055] Such as figure 1 As shown, the integrally sealed electric barrier provided by the present invention includes a barrier seat, which includes a lower cover 34 made of polyethylene engineering plastics, and a flange is provided on the upper surface of a bottom cover 32, which is inserted into the lower cover. 34, on the side wall of the lower cover 34, hexagon socket screws 31 are set to fix the flanges of the lower cover 34 and the bottom cover 32 so that the bottom cover 32 is fixed on the lower cover 34, thus, the lower end of the lower cover 34 is sealed by the hexagon socket screws 31. A metal bottom cover 32 has been fixedly connected, and a lower plate 29 is fixed on the upper flange of the bottom cover 32. On the side wall above the lower plate 29, a number of hexagon socket screws 30 are evenly screwed in the circumferential direction, and one end of the screw rod of the screw is The lower cover 34 is inserted into the upper surface of the lower plate in a sealed...

Embodiment 2

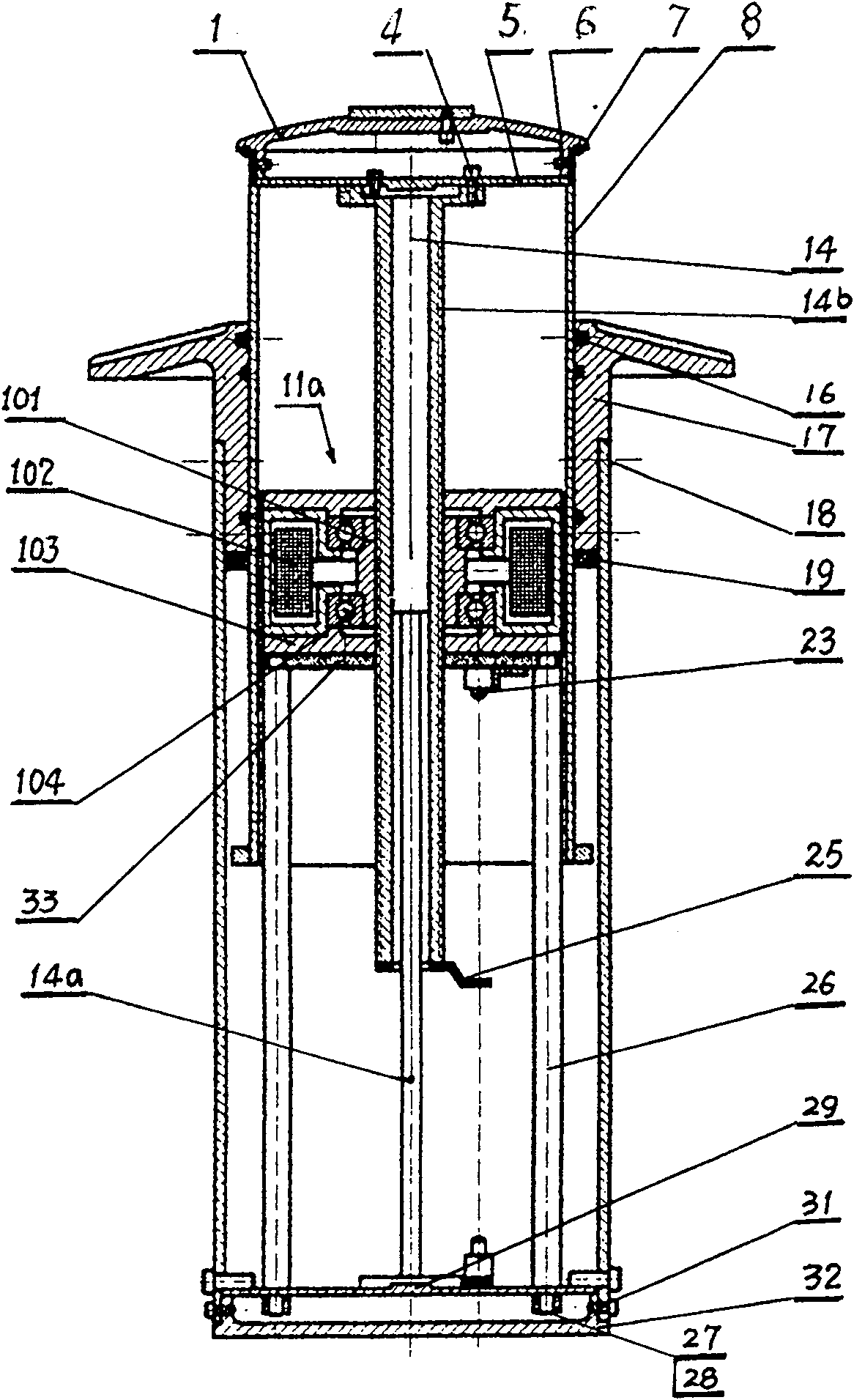

[0068] Such as figure 2 Shown is another structure of the integrally sealed electric barrier. The structure of the barrier seat, the barrier pile, and the gravity balancer is basically the same as that of Embodiment 1, the difference is that the balance cylinder in the gravity balancer is driven to move up and down relative to the piston, and then drives the barrier pile relative to the barrier. The transmission mechanism in the driving source for the rise and fall of the seat, the rack and pinion transmission mechanism is a screw transmission mechanism. Such as figure 2 As shown, threads are provided on the outer peripheral wall of the cylinder body of the balance cylinder 14 to form a threaded cylinder 14 b, or threads are directly processed on the outer wall of the balance cylinder 14 . Similarly, the upper end of the balance cylinder is fixed on the upper top plate 5 of the barrier pile, and the lower end of the piston rod 14a is fixed on the lower plate 29 on the barr...

Embodiment 3

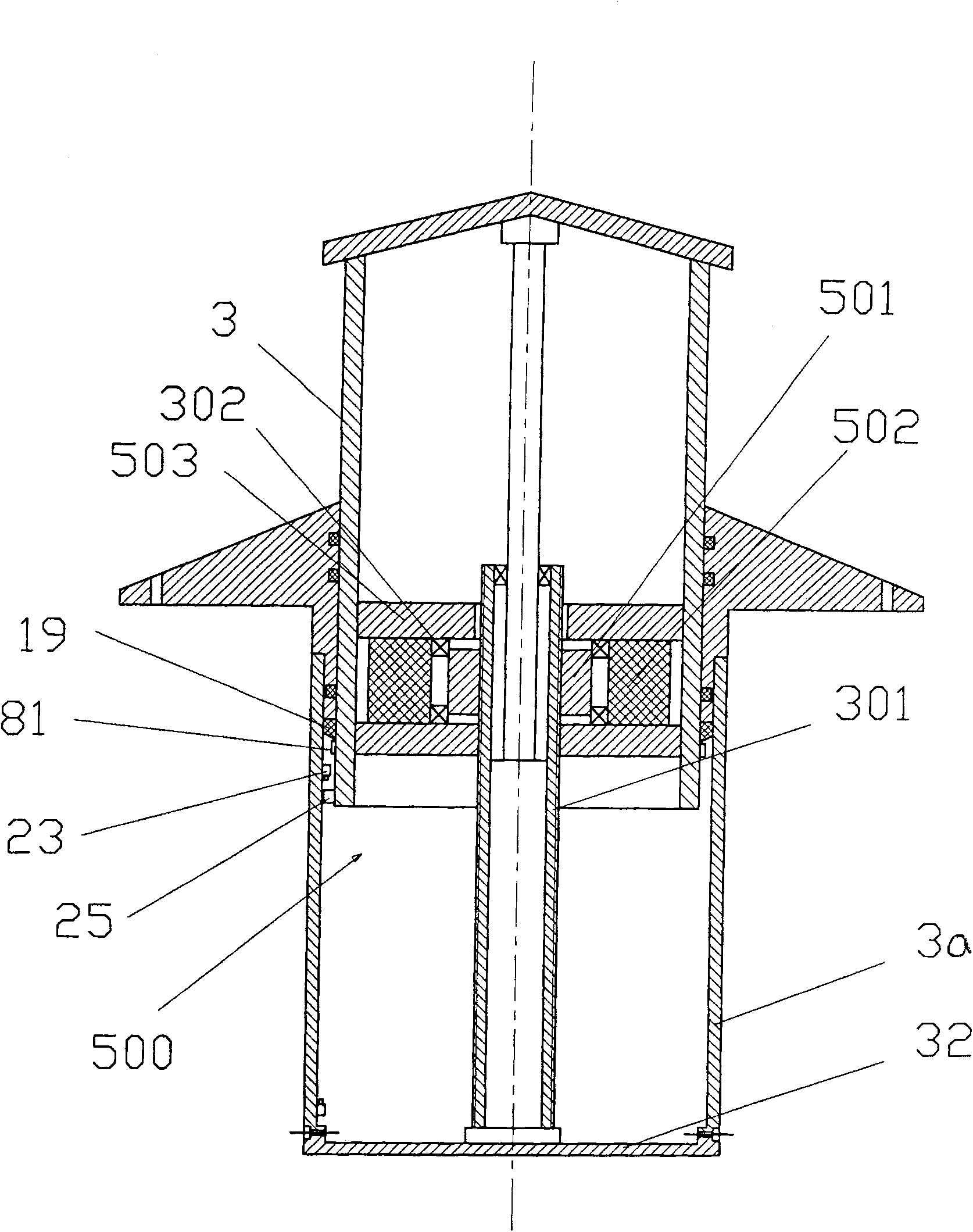

[0072] Such as Figure 2a As shown, in this embodiment, the transmission device is still a screw transmission mechanism, but its structure can be changed to: a cylinder 301 is tightly fitted on the outer peripheral wall of the cylinder body of the balance cylinder, and a cylinder 301 is arranged on the cylinder side wall. Screw threads are provided to form a threaded cylinder, and the end of the balance cylinder is fixed on the bottom cover 32 on the barrier seat, or is fixed on the lower plate fixed on the bottom cover (in the figure) as in the previous embodiment. not shown), the end of the piston rod is fixed on the closed upper bottom plate of the barrier pile, that is, the upper cover 1, or on the upper bottom plate, that is, the upper top plate (not shown) that is arranged below the upper cover 1 A screw hole is provided in the middle of the rotor 501 of the motor 500, and the rotor 501 of the motor is screwed on the threaded cylinder 301 of the balance cylinder; the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com