Low-rosin and cleaning-free welding accessory without halogen for lead-free welding grease

A lead-free solder paste, rosin type technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of solder joint corrosion, excessive post-soldering residues, etc., and achieve good soldering performance, Eliminate cleaning process, no irritating odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

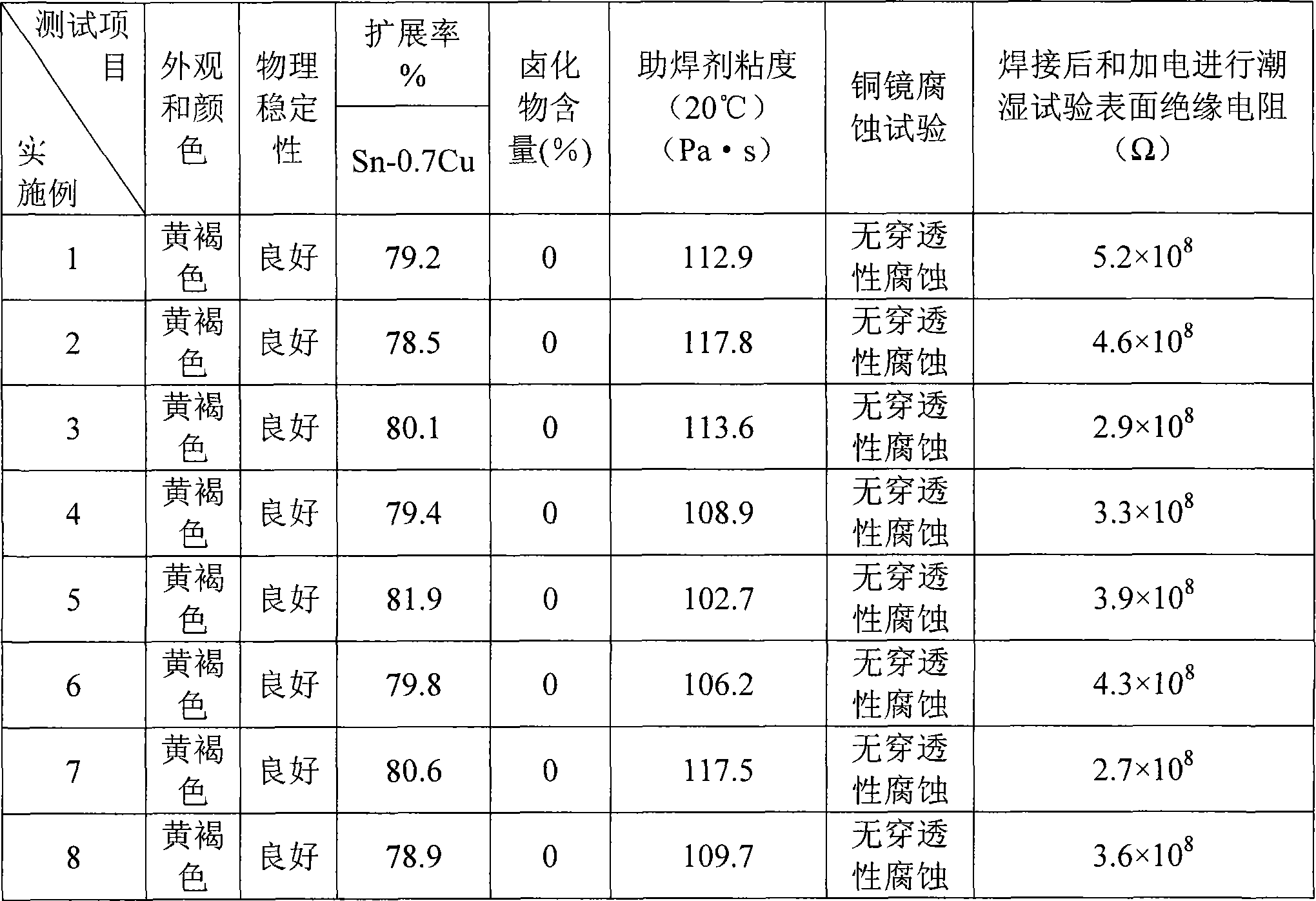

Examples

Embodiment 1

[0024] polymerized rosin 28

[0025] Succinic acid 13

[0026] Polyethylene glycol 2000 3

[0027] Diethylene glycol diethyl ether 26

[0028] Diethylene glycol 12

[0029] Hydrogenated castor oil 3

[0030] Paraffin 2

[0031] Triethanolamine 8

[0032] Polyacrylic resin 3

[0033] Octylphenol ethoxylate 2

[0034] Specific preparation method: The specific preparation method is a conventional method. First add a high boiling point solvent into a reaction kettle with a stirrer, weigh an appropriate amount of activator and add it to the reaction kettle, heat to control an appropriate temperature, stir to dissolve it completely, and add a polymer After the rosin is completely dissolved, add stabilizers, paste agents, thixotropic agents, surfactants, and then add corrosion inhibitors, stir until the solution is clear and transparent, let stand, and cool with water, that is, rosin-type halogen-free for lead-free solder paste No-clean flux. Then mix flux and lead-free sold...

Embodiment 2

[0036] polymerized rosin 20

[0037] Disproportionated Rosin 5

[0038] Adipic acid 15

[0039] Glutaric acid 5

[0040] Octylphenol ethoxylate 2

[0041] Polyethylene glycol 2000 5

[0042] Diethylene glycol monoethyl ether 22

[0043] Ethylene glycol 15

[0044] Hydrogenated castor oil 4

[0045] Triethylamine 1

[0046] Acrylic 1

[0047] Paraffin 5

[0048] Preparation method is identical with example 1.

Embodiment 3

[0050] Hydrated Rosin 10

[0051] Disproportionated Rosin 10

[0052] amino acid 16

[0053] Nonylphenol ethoxylates 6

[0054] Polyethylene glycol 4000 4

[0055] Diethylene glycol monocaprylyl ether 20

[0056] Ethylene glycol 23

[0057] Hydrogenated castor oil 0.5

[0058] Benzotriazole 4

[0059] Polyacrylic resin 6

[0060] Paraffin 0.5

[0061] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com