Producer of high-flux continuous homogeneous emulsion drop

A preparation device, high-throughput technology, applied in chemical instruments and methods, dissolving, mixers, etc., can solve problems such as large power, continuous production difficulties, particle size distribution effects, etc. The effect of material activity and low speed requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

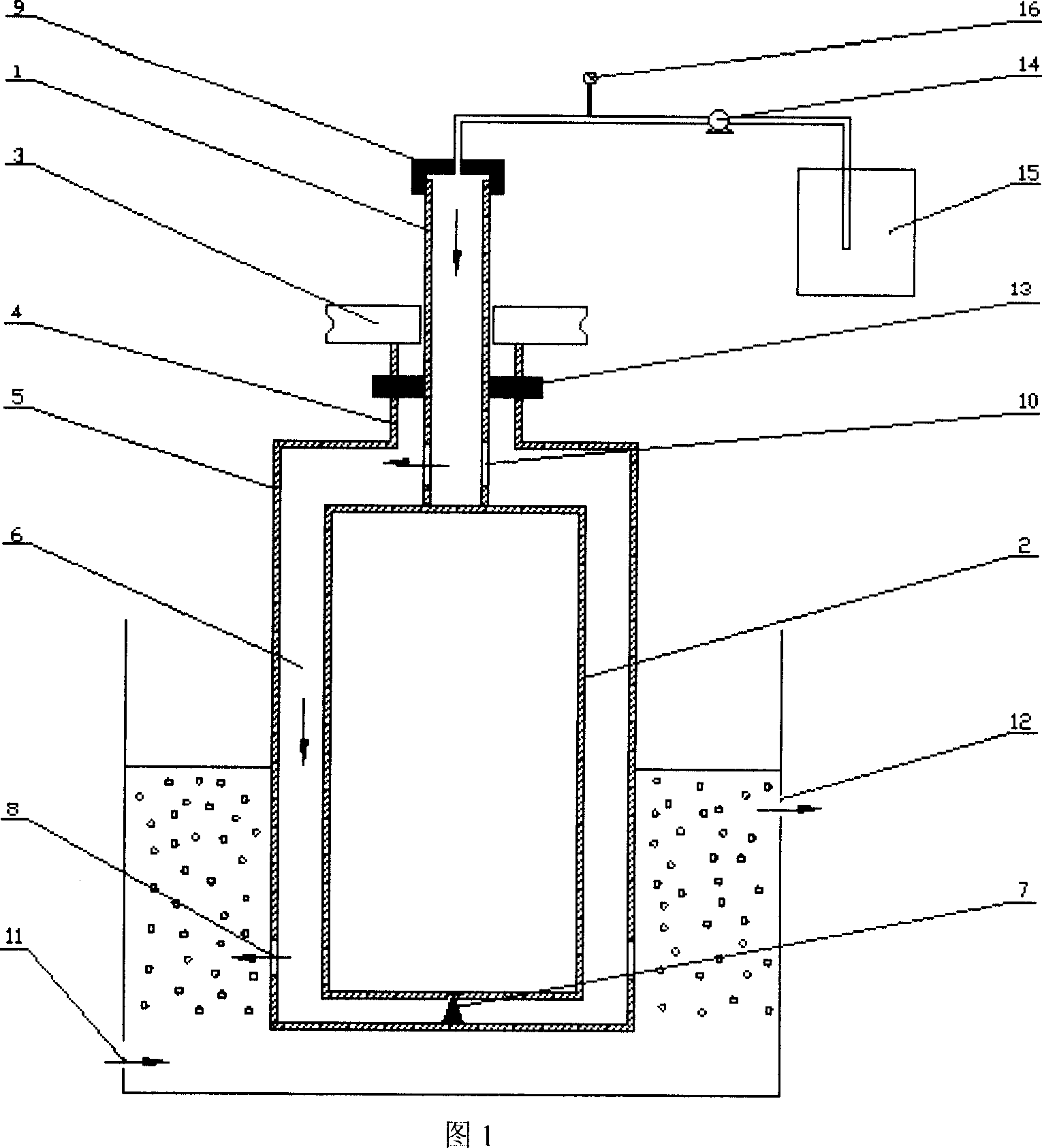

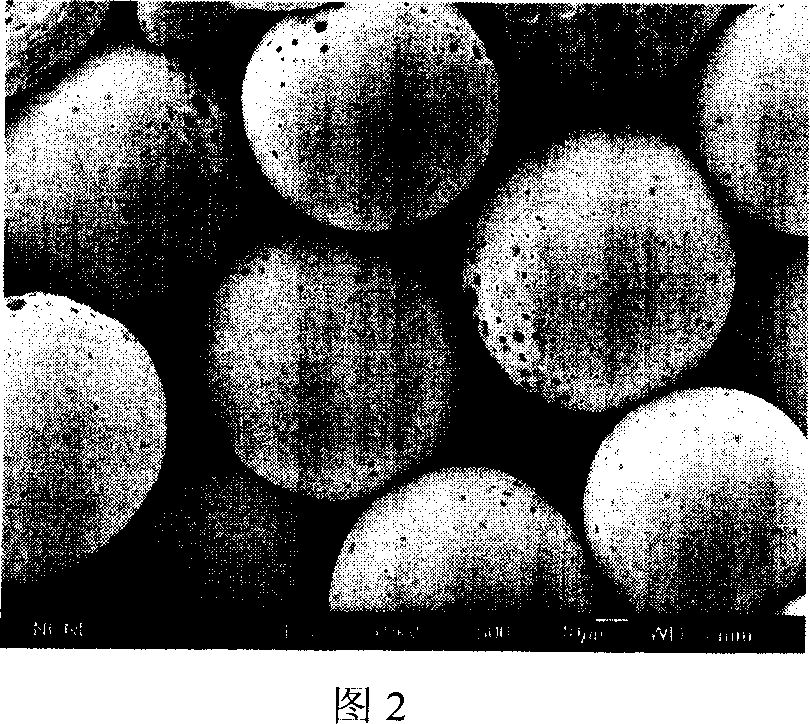

[0025] Embodiment 1. High-throughput continuous uniform emulsion droplet preparation device prepares polylactic acid microspheres with uniform particle size (rotating speed 400rpm)

[0026] Pour 800mL of dichloromethane solution (oil phase) dissolved with 5g of polylactic acid (molecular weight: 100,000) into a 1000mL dispersed phase storage tank, and pump it into the device continuously, controlling the pressure at 1.2bar. 3200mL of 1.0wt% polyvinyl alcohol (PVA) deionized aqueous solution (water phase) was poured into the container continuously through the feed port (11). The oil / water emulsion was prepared by using the high-throughput continuous uniform emulsion droplet preparation device shown in Figure 1 (the aperture of the outlet is 1mm). The rotation speed of the belt runner is 400rpm, and the prepared emulsion is continuously output from the outlet (12). Then, the above obtained emulsion was stirred with a magnetic mechanical stirrer at 150 rpm for 5 hours to ensure ...

Embodiment 2

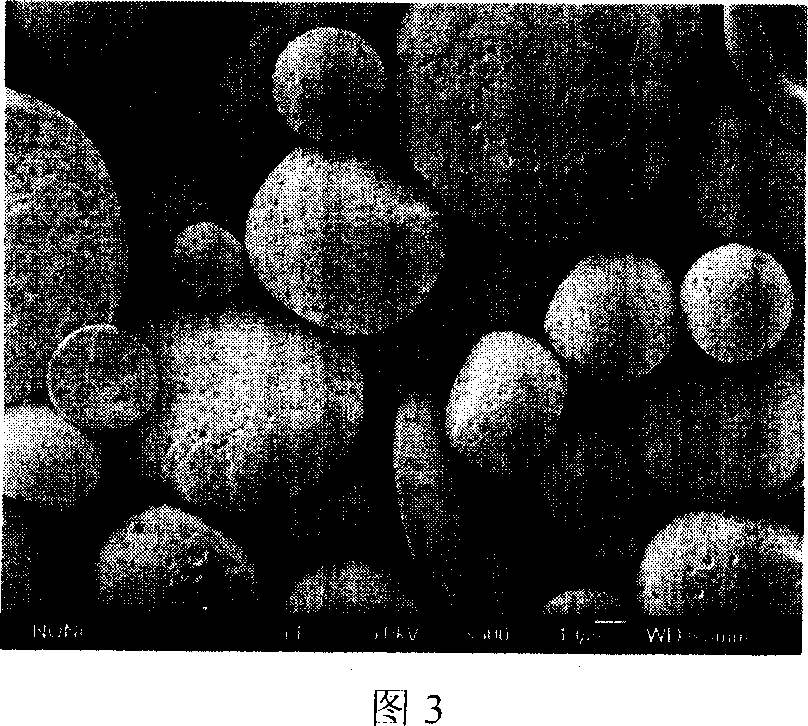

[0030] Embodiment 2. High-throughput continuous uniform emulsion droplet preparation device prepares polylactic acid microspheres with uniform particle size (rotating speed 300rpm)

[0031] Pour 800mL of dichloromethane solution (oil phase) dissolved with 5g of polylactic acid (molecular weight: 100,000) into a 1000mL dispersed phase storage tank, and pump it into the device continuously, controlling the pressure at 1.2bar. 3200mL of 1.0wt% polyvinyl alcohol (PVA) deionized aqueous solution (water phase) was poured into the container continuously through the feed port (11). The oil / water emulsion was prepared by using the high-throughput continuous uniform emulsion droplet preparation device shown in Figure 1 (the aperture of the outlet is 1 mm). The rotation speed of the belt runner is 300rpm, and the prepared emulsion is continuously output from the outlet (12). Then, the above obtained emulsion was stirred with a magnetic mechanical stirrer at 150 rpm for 5 hours to ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com