Method for synthesizing sphene

A synthesis method and technology of sphene are applied in the fields of high radioactive waste disposal, solidification treatment of artificial rock, and synthesis of sphene, which can solve the problems of expensive raw materials, secondary pollution, complicated process, etc., to simplify the solidification treatment process, The effect of reducing secondary pollution and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

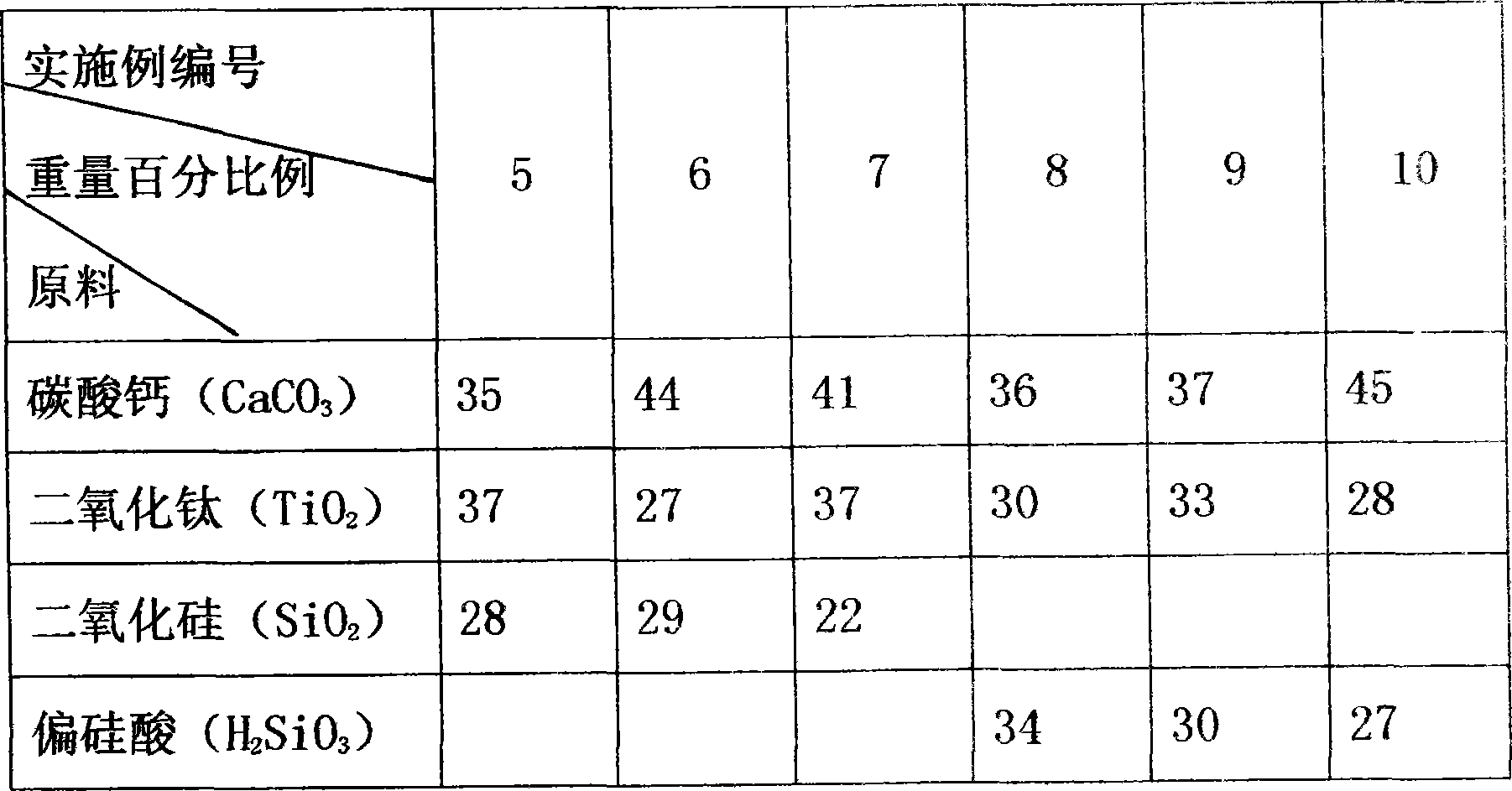

Embodiment 1

[0031] A synthetic method of titanite, comprising the following steps:

[0032] (1) Raw material and composition: take raw material calcium carbonate (CaCO 3 ), titanium dioxide (TiO 2 ) and silicon dioxide (SiO 2 ); The percentage by weight of raw materials is composed of: silicon dioxide (SiO 2 ) 25.02wt.%, calcium carbonate (CaCO 3 )41.7wt.%, titanium dioxide (TiO 2 ) 33.28wt.%.

[0033] (2) Ball milling and drying: the raw materials are batched according to the weight percentage, and then put into a ball mill (such as a planetary mill) for wet fine grinding for 240 minutes, so that the powder is fine enough and mixed uniformly; The material is dried at 70°C;

[0034] (3) Calcination: calcining the finely ground and dried material at 1320°C for 30 minutes to obtain high-purity titanite (CaTiSiO 5 ).

Embodiment 2

[0036] A kind of synthetic method of titanite, with metasilicate (H 2 SiO 3 ), calcium carbonate (CaCO 3 ), titanium dioxide (TiO 2 ) is the raw material, and the weight percentage of the raw material is composed of: metasilicate 30.27wt.%, CaCO 3 38.78wt.%, TiO 230.95 wt.%. Weigh the above-mentioned substances according to the weight percentage of the raw materials, and finely grind them in a ball mill (such as a planetary mill) for 210 minutes to obtain powders with fine particle size and uniform composition. The finely ground powder was dried at 50°C, calcined at 1280°C and kept for 30 minutes to obtain high-purity titanite (CaTiSiO 5 ).

Embodiment 3

[0038] A kind of synthetic method of titanite, with calcium carbonate (CaCO 3 ), titanium dioxide (TiO 2 ) and silicon dioxide (SiO 2 ) is a raw material; the weight percent example of raw material consists of: silicon dioxide 25.52wt.% (weight percent), CaCO 3 40.7wt.%, TiO 2 33.78 wt.%. Weigh the above-mentioned substances according to the weight percentage of raw materials, and finely grind them in a ball mill (such as a planetary mill) for 240 minutes to obtain powders with fine particle size and uniform composition. The finely ground powder was dried at 70°C, calcined at 1290°C and held for 60 minutes to obtain high-purity titanite (CaTiSiO 5 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com