Multifunction underwell hydraulic oil producing device

An oil production device and multi-functional technology, which is applied in the field of multi-functional downhole hydraulic oil production devices, can solve the problems of large power consumption, increased floor space, and inconvenient management, and achieve easy operation and management, small floor space, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

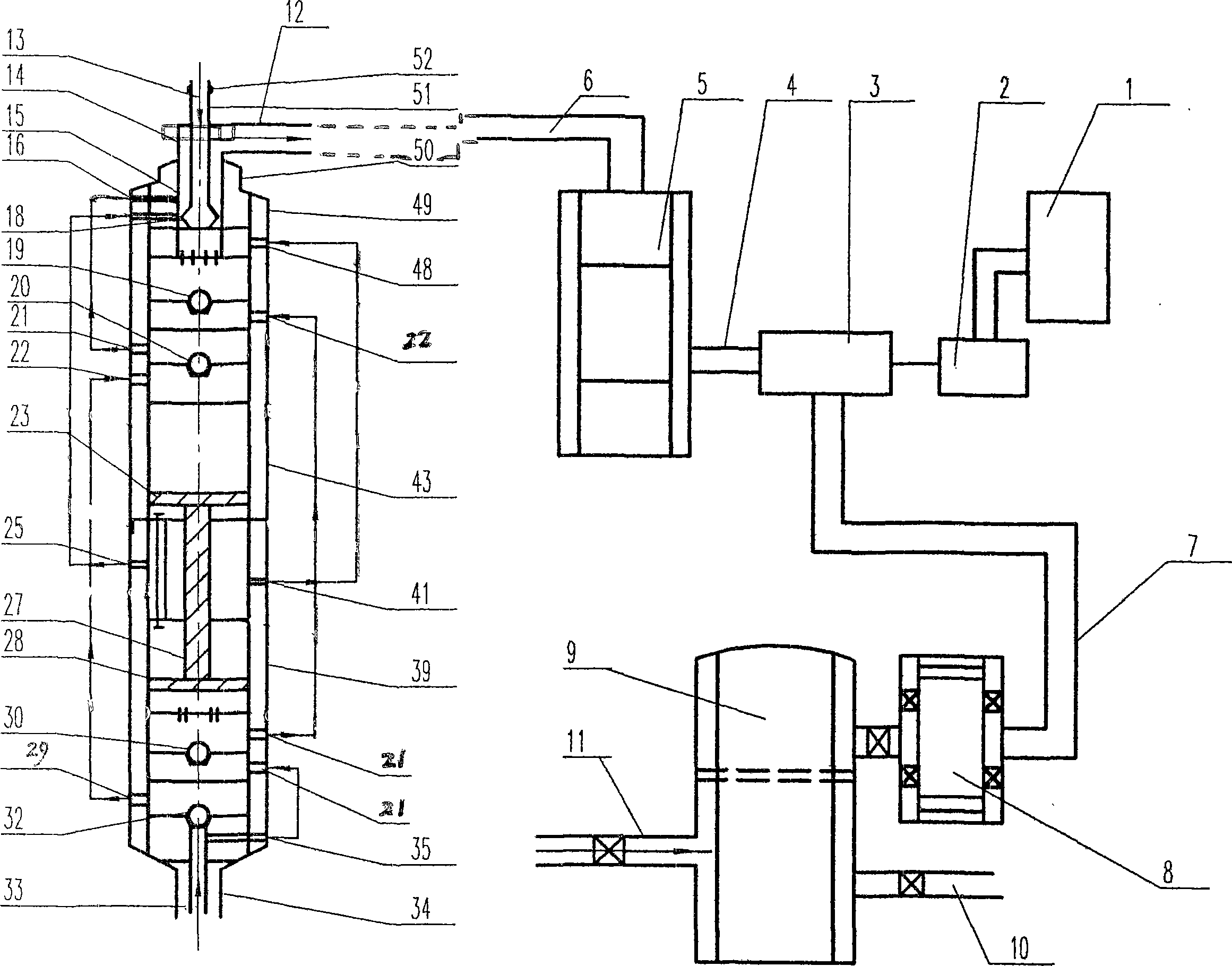

[0020] The voltage regulating cabinet 1 is a rectangular iron cabinet with an electronic circuit power supply motor 2, which is connected to the motor 2 through wires, and the high-pressure pump 3 is the power source. The upper piston 23 and the lower piston 28 in the hydraulic pump move, and the liquid flows through the high-pressure pipeline 4; the pump inlet pipeline 7 is respectively connected with the high-temperature heating furnace 5, the filtering device 8, and the crude oil filter 9, and the high-temperature heating furnace 5 is a wellhead The water jacket heating furnace is connected to the high-pressure pipeline 4 through the pipeline connected by the inner coil, which can send the high-temperature liquid in the pipeline into the well. The crude oil filter 9 is cylindrical in shape and has a metal filter inside to filter Due to the sand particles carried in the crude oil, the high-pressure pipeline 4 is connected to the wellhead 14 through the surface high-pressure p...

Embodiment 2

[0022] The downhole hydraulic oil extraction pump 49 mainly includes an upper pump barrel 43, a lower pump barrel 39, an upper piston 23, a lower piston 28, a piston pull rod 27, an upper valve ball 19, a lower valve ball 20, an upper oil inlet valve ball 30, a lower inlet valve ball Oil valve ball 32, oil inlet channel 33 (the channel acts as the inlet of crude oil in the well), and high-pressure power fluid nozzle nozzle 18, crude oil pump outlet 21 on the upper and lower pump barrel walls, crude oil pump inlet 22, and liquid inlet reversing A valve 25, a crude oil suction port 29, a power fluid inlet 48, and a power fluid discharge port 41 are formed. The nozzle 18 of the high-pressure power fluid nozzle is a conical cylindrical nozzle with 4 circular holes of the same diameter, through which the high-pressure liquid flow is injected into the downhole hydraulic pump to force the piston to move up and down.

Embodiment 3

[0024] When the present invention works, the fluid medium is sucked into the pump by the surface high-pressure pump 3 and after being pressurized and heated, it is sent into the downhole hydraulic oil production pump 49 in the well through the hollow sucker rod 51 in the wellhead 14.

[0025] The downhole hydraulic oil extraction pump is composed of a two-way hydraulic cylinder pump barrel, an upper pump barrel 43 and a lower pump barrel 39. When working, the hydraulic pressure is used to push the upper piston 23 and the lower piston 28 in the hydraulic cylinder to move up and down, and the This creates a vacuum pressure in the cylinder, so that the piston of the pump body performs continuous and alternate work of suction and discharge respectively, and completes the suction and discharge actions under the action of the liquid inlet reversing valve 25. When it is raised to the ground, at this time, part of the well fluid is input into the pump station, and the other part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com