Process of casting cylinder head of diesel engine

A cylinder head and diesel engine technology, which is applied to casting molding equipment, casting molds, casting mold components, etc., can solve the problems of low inner cavity smoothness and loose tissue, and achieve the effect of simple and practical operation, reducing shrinkage porosity and ensuring smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

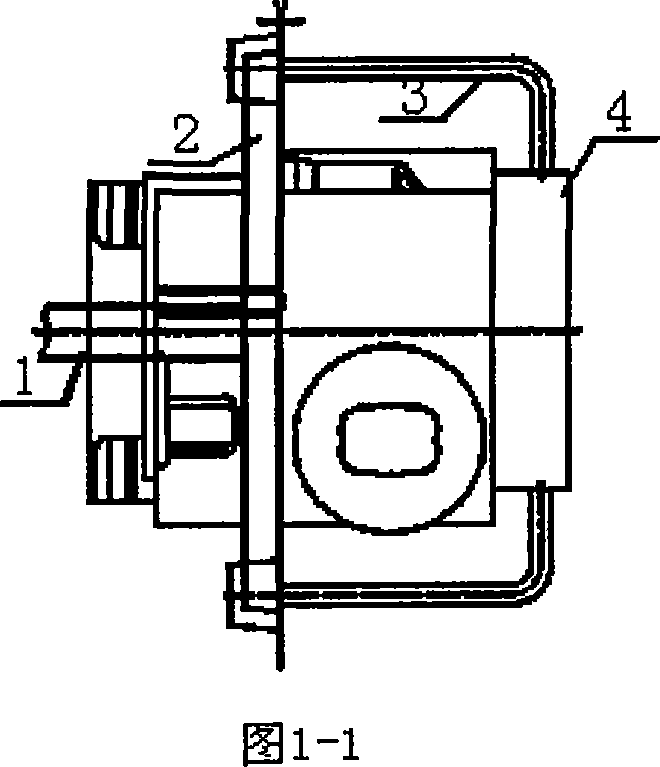

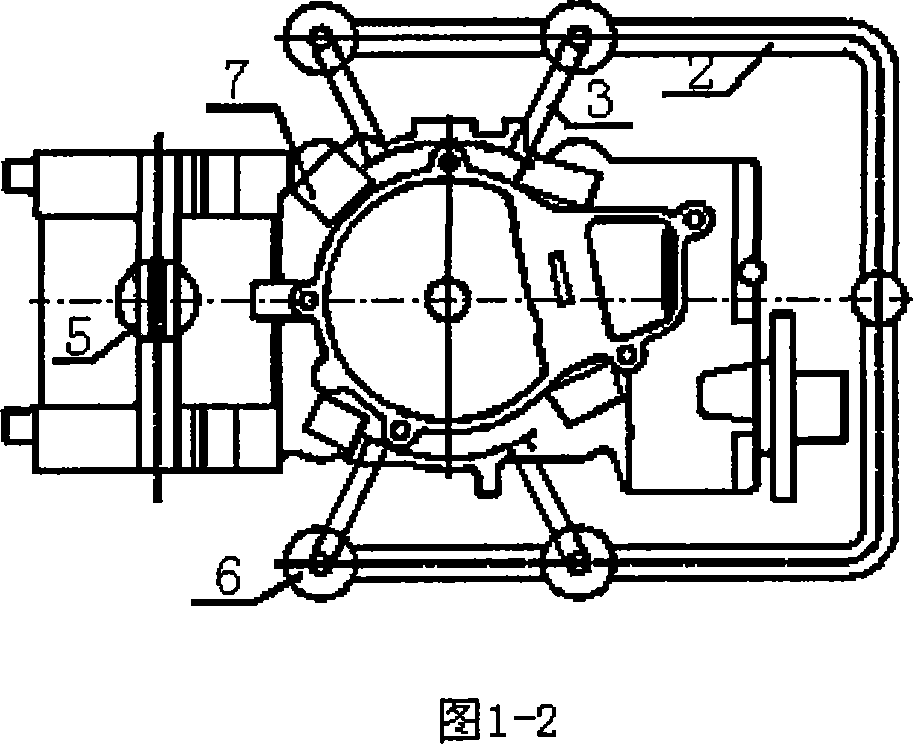

[0020] As shown in Figure 1, a two-box molding and bottom pouring gating system is adopted.

[0021] Its technological process is:

[0022] (1) Manufacture the mold according to the casting process drawing.

[0023] (2) Modeling and core making. Due to the use of resin sand for production, attention should be paid to the air outlet of the mud core, the compactness of the sand core and the accuracy of the position of the cold iron during the molding and core making process, and the curing speed of the core sand should be moderate.

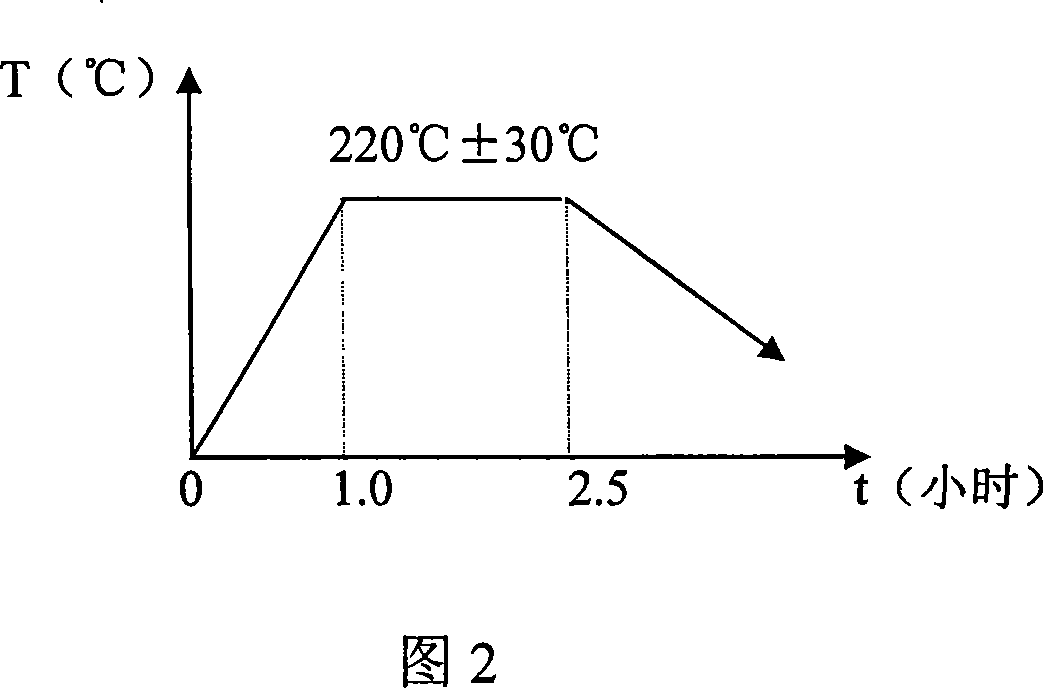

[0024] (3) Drying of molds and sand cores. In order to ensure that the mold and sand core are thoroughly baked, dried, and not cracked, the heating and cooling speeds must be strictly controlled. For details, see Figure 2, the resin sand drying process specification.

[0025] (a) Heating stage: In order to prevent the mold and sand core from cracking, the heating rate is controlled below 250°C / hour;

[0026] (b) Heat preservation stage: In orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com