Biodegradable slow released medicated rack for myocardial blood transport reconstruction and its preparation process

A biodegradable and biodegradable technology, applied in the field of biodegradable drug slow-release stents and preparations, can solve problems such as short half-life, blood pressure drop, and difficulty in promoting angiogenesis, so as to prevent thrombosis and prevent myocardial autogenesis closed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

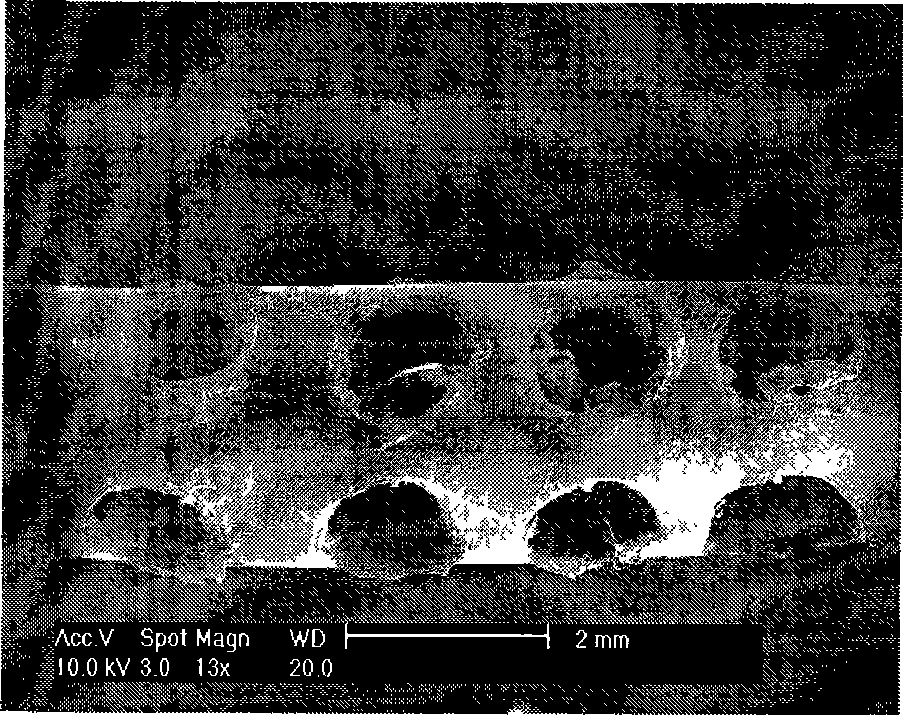

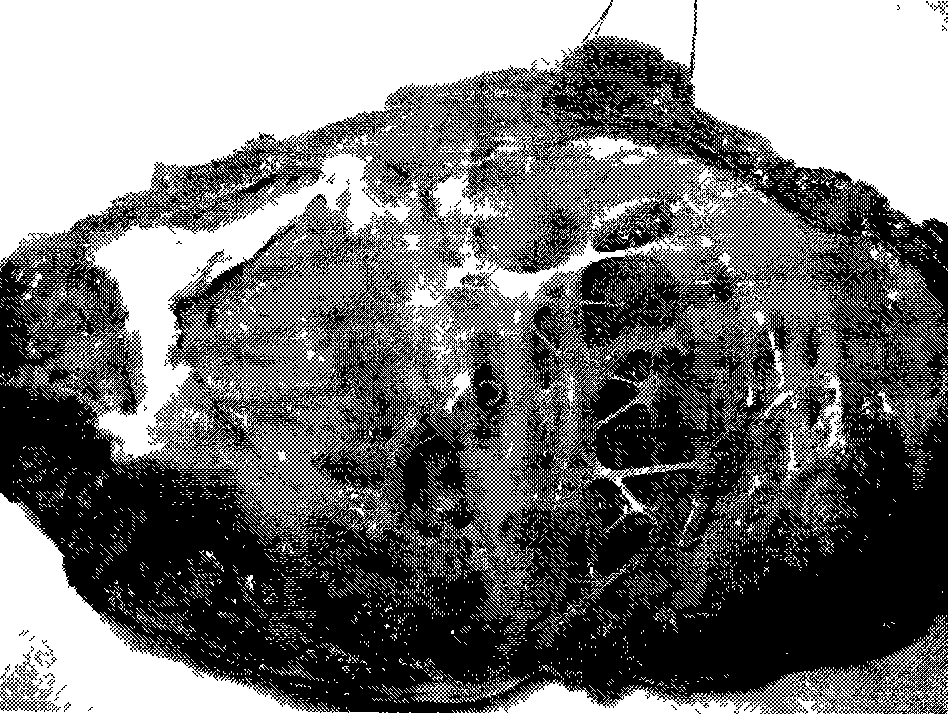

Embodiment 1

[0027] A preparation method for a biodegradable drug slow-release stent for myocardial revascularization, comprising the following steps: (1) using polycaprolactone with a molecular weight of 30,000 as raw material, extruding it into an outer shell through melting and screw extruding Diameter is 3mm, and wall thickness is the hollow inner tube of 0.2mm, cut into the hollow inner tube of 1cm in length; , be made into the polymer solution that the concentration is 15% (g / ml), fully stir, dissolve; After the solution is poured into the mold of polytetrafluoroethylene, dry naturally at room temperature, form a film after the solvent volatilizes, by controlling pouring solution The amount of control the thickness of film, the molded thickness is 0.2mm, is prepared into the strip film that width is 2cm, and length is 3cm; Get basic fibroblast growth factor and heparin and spread evenly on the film, fold then, prepare into the strip film of width 1cm drug film, each drug film contain...

Embodiment 2

[0029] A preparation method for a biodegradable drug slow-release stent for myocardial revascularization, comprising the following steps: (1) using polylactic acid as raw material, by melting, extruding with a screw to form an outer diameter of 5mm and a wall thickness of A hollow inner tube of 0.5 mm is cut into a hollow inner tube with a length of 1 cm; (2) chloroform is added to polycaprolactone-polylactic acid copolymer (molar ratio is 60 / 40), and the concentration is 30 % (g / ml) of the polymer solution, fully stirred and dissolved; after the solution was poured into a polytetrafluoroethylene mold, it was naturally dried at room temperature, and a film was formed after the solvent evaporated, and the thickness of the film was controlled by controlling the amount of the pouring solution , the molding thickness is 0.2 mm, and it is prepared into a strip film with a width of 2 cm and a length of 3 cm; get vascular endothelial growth factor and heparin evenly spread on the film...

Embodiment 3

[0031] A preparation method for a biodegradable drug slow-release stent for myocardial revascularization, comprising the following steps: (1) using polyglycolic acid as a raw material, through melting, screw extruding into an outer diameter of 1mm, a wall thickness of It is a hollow inner tube of 0.1 mm, cut into a hollow inner tube with a length of 0.5 cm; (2) tetrahydrofuran is added to polydioxane to form a polymer solution with a concentration of 5% (g / ml), fully Stir and dissolve; after the solution is poured into the mold of polytetrafluoroethylene, it is naturally dried at room temperature, and a film is formed after the solvent evaporates, and the thickness of the film is controlled by controlling the amount of the casting solution. The thickness of the mold is 0.2mm, and the width is prepared as 1cm strip film with a length of 1cm; spread vascular endothelial growth factor and heparin evenly on the film, and then fold it to prepare a drug film with a width of 0.5cm, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com