Flip type drying oven

A flip-top, oven technology, applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the problems of easily damaged robot body safety accident, abnormal operation of the oven, etc., to avoid safety accidents, prolong the The effect of useful life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

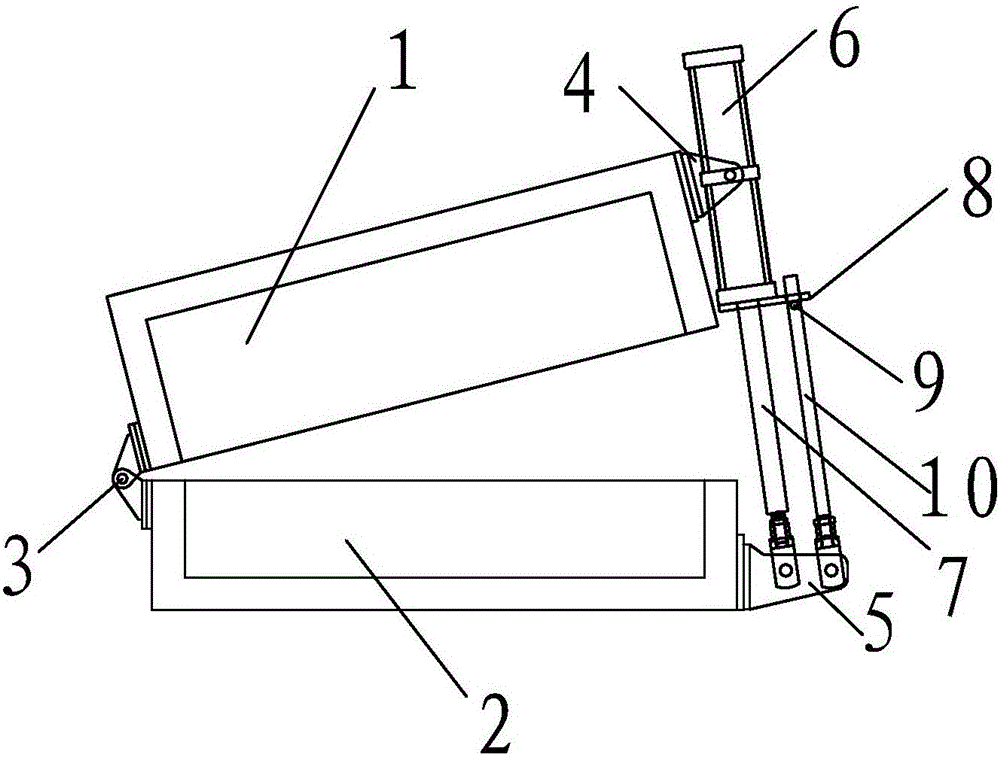

[0011] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0012] The invention provides a clamshell oven, which can avoid automatic closing of the upper and lower covers of the oven caused by cylinder failure or other unexpected conditions, prolong the service life of the machine, and ensure safe production.

[0013] like figure 1 and 2 Shown, a kind of clamshell oven, it comprises lower cover 2 and a upper cover 1, upper and lower cover (1,2) are connected by a hinge 3, and a side of described upper cover 1 and lower cover 2 is respectively provided with a The upper connecting portion 4 and the lower connecting portion 5, the upper connecting portion 4 connects the middle part of a cylinder 6, the lower connecting portion 5 connects the piston rod 7 of the cylinder 6, the end of the cylinder 6 is provided with a connecting plate 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com