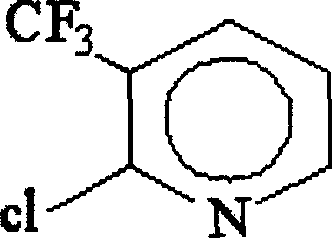

Preparation method of 2,3-dichlorin-5-trifluoro picoline

A technology of trifluoromethyl pyridine and methyl pyridine is applied in the field of preparation of pesticide intermediate 2-chloro-3-trifluoromethyl pyridine, and can solve the problems of difficult separation of tar, low product purity, difficult equipment to solve and the like , to achieve the effect of low production cost, high purity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Chlorination

[0030] Into a 1000L chlorination kettle, pump 200kg of dried raw materials 2-chloro-3-picoline, 6kg of phosphorus trichloride, 1000kg of carbon tetrachloride, and 5kg of azobisisobutyronitrile. Turn on the light source (two 800W ultraviolet lights), heat up the jacket with steam, open the tail gas system, and operate with a slight negative pressure (-0.02MPa). When the temperature in the kettle reaches 80°C, start to pass chlorine, and the chlorine flow rate is 45kg / h, first fast and then slow, keep the reflux reaction, through sampling analysis, G.C detects that the content of trichloride reaches more than 90% and the content of dichlorine is less than 5% is the end of the reaction. If you need to continue the reaction, take a sample and analyze it every 2 hours until it is qualified. .

[0031] After passing the test, stop the chlorine flow, pump the reaction solution into the carbon tetrachloride distillation kettle, and steam the carbon tetrachl...

Embodiment 2

[0038] With the technological operation step of embodiment 1. The different conditions are:

[0039] The catalyzer that the chlorination reaction stage adopts is benzoyl peroxide meter 15kg. Organic solvent adopts dichloromethane 1200kg.

[0040] The catalyst antimony pentachloride is used in the fluorination reaction stage, the addition amount is 1kg, the reaction temperature is 170-180°C, the pressure is 7MPa, and the reaction time is 24 hours.

[0041] The product purity is above 98%, and the yield is 85%.

Embodiment 3

[0043] With the technological operation step of embodiment 1. The different conditions are:

[0044] The catalyst used in the chlorination reaction stage is 7kg of tungsten hexachloride and 3kg of phosphorus trichloride. Organic solvent adopts dichloronitrobenzene 2000kg.

[0045] In the fluorination reaction stage, the catalyst antimony pentafluoride is used, the addition amount is 0.7kg, the reaction temperature is 170-180°C, the pressure is 8MPa, and the reaction time is 26 hours.

[0046] The product purity is above 98%, and the yield is 86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com