Stainless steel chemical pigmenting liquid and chemical pigmenting method

A chemical coloring, stainless steel technology, applied in metal material coating process, superimposed layer plating, coating and other directions, can solve the problems of insufficient uniformity and reproducibility of acid chemical coloring of stainless steel, and achieve bright color and color film. Uniform, reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

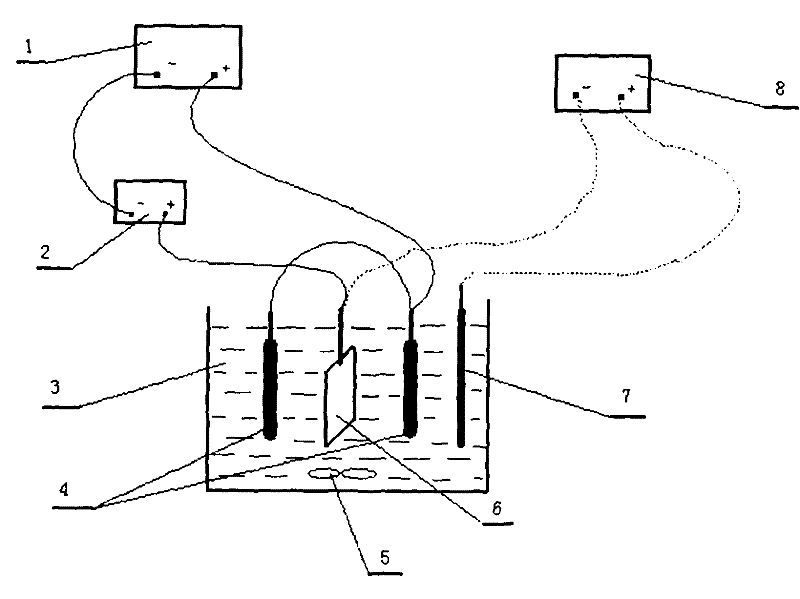

[0022] Example figure 1 Middle: implement as follows:

[0023] (1) Stainless steel surface pretreatment

[0024] The stainless steel test piece 6 is pre-treated by water washing, degreasing, water washing, polishing, water washing, activation, water washing, etc., to remove the dirt layer and oxide layer on the surface of the stainless steel.

[0025] (2) One-step treatment of coloring-hardening film

[0026] The pre-treated stainless steel test piece 6 is used as the cathode, immersed in the coloring solution 3, the formula of the coloring solution 3: concentrated H 2 SO 4 490g / L, CrO 3 250g / L, (NH 4 ) 6 Mo 7 o 24 4H 2 O 7.0g / L, ZnSO 4 5.0g / L, MnSO 4 4.0g / L, OP-106.0g / L, solution temperature 65℃, according to the attached figure 1 Connect the two loops of coloring and potential measurement, use DC power supply 1, and control the current density to 6.3mA / dm 2 , Carry out chemical coloring with small electric current, wash with flowing water after coloring.

[002...

Embodiment 2

[0034] (1) Stainless steel surface pretreatment

[0035] With embodiment 1.

[0036] (2) One-step treatment of coloring-hardening film

[0037] The pre-treated stainless steel test piece 6 is used as the cathode, immersed in the coloring solution 3, the formula of the coloring solution 3: concentrated H 2 SO 4 490g / L, CrO 3 250g / L, (NH 4 ) 6 Mo 7 o 24 4H 2 O 7.0g / L, ZnSO 4 5.0g / L, MnSO 4 4.0g / L, sodium dodecylbenzenesulfonate 6.0g / L, solution temperature 65℃, according to the attached figure 1 Connect the two loops of coloring and potential measurement, use AC power supply 1, and control the current density to 5.2mA / dm 2 , Carry out chemical coloring with small electric current, wash with flowing water after coloring.

[0038] Shading result:

[0039] Potential difference / mV

[0040] Next step is with embodiment 1.

Embodiment 3

[0042](1) Stainless steel surface pretreatment

[0043] With embodiment 1.

[0044] (2) Coloring - hard film treatment

[0045] The pre-treated stainless steel test piece 6 is used as the cathode, immersed in the coloring solution 3, the formula of the coloring solution 3: concentrated H 2 SO 4 490g / L, CrO 3 250g / L, (NH 4 ) 6 Mo 7 o 24 4H 2 O 7.0g / L, ZnSO 4 5.0g / L, MnSO 4 4.0g / L, cetyltrimethylammonium bromide 1.5g / L, solution temperature 65℃, according to the attached figure 1 Connect the two loops of coloring and potential measurement, use pulse power supply 1, and control the current density to 7.0mA / dm 2 , Carry out chemical coloring with small electric current, wash with flowing water after coloring.

[0046] Shading result:

[0047] Potential difference / mV

[0048] Next step is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com