Novel green fruit and vegetable coating preservative and preparation process thereof

A film-coating preservative and a technology for the preparation process, which are applied in the direction of protecting fruits/vegetables with a coating protective layer, etc., can solve the problems of film cracking, poor fresh-keeping effect, poor toughness, etc., and achieve low cost and improved film formation. effect, effect of good quality characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

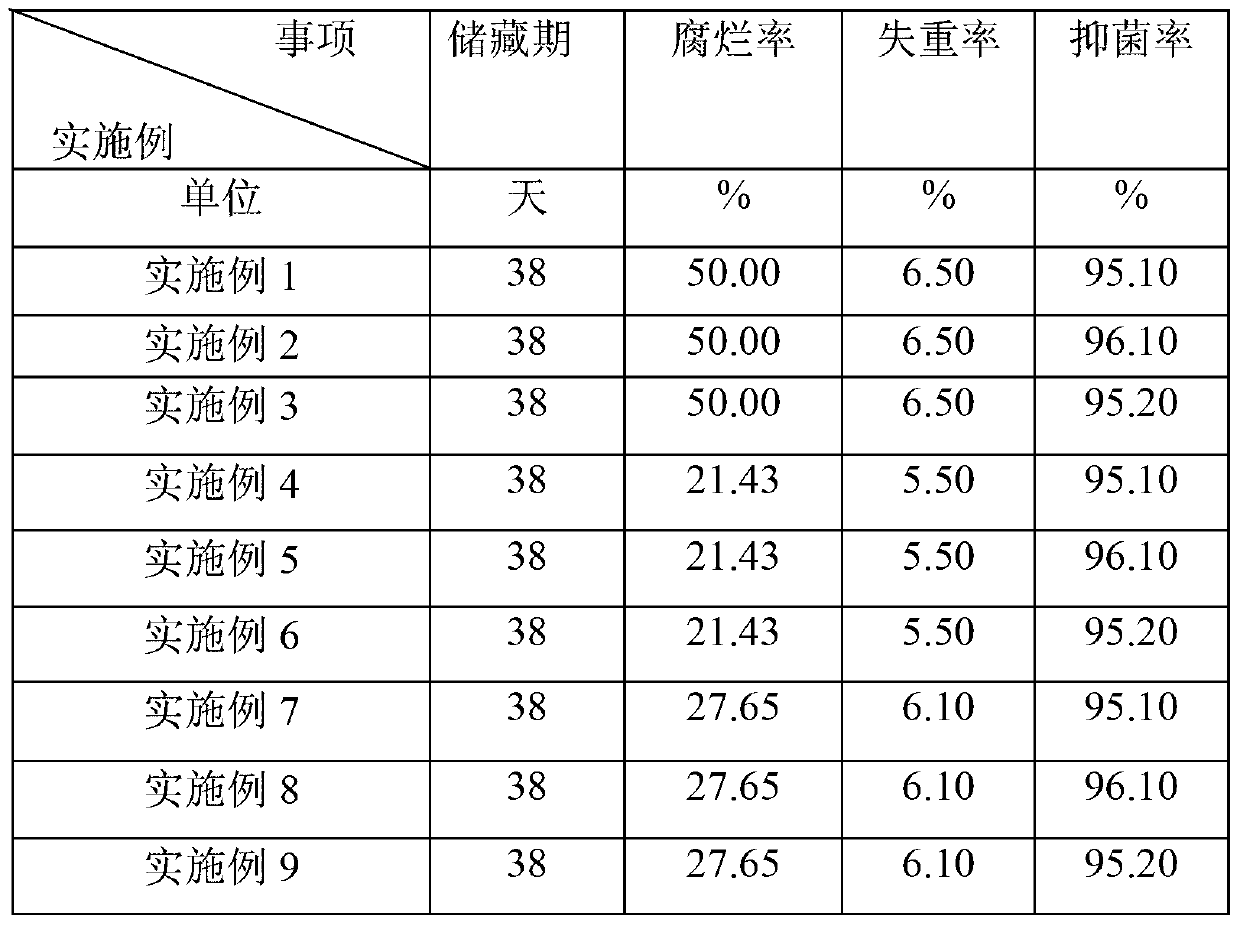

Examples

Embodiment 1

[0025] 1) The natural chitosan is subjected to 30kGy electron beam irradiation treatment to obtain degraded chitosan, for subsequent use;

[0026] 2) Anhydrous acetic acid is dissolved in distilled water to be prepared into an acetic acid solution with a volume concentration of 1mL / 100mL, and then the degraded chitosan is dissolved in the acetic acid solution to prepare a chitosan solution with a mass percent concentration of 0.5%. ;

[0027] 3) Dissolving konjac fine powder in distilled water, conventionally stirring, and preparing a solution of konjac fine powder with a concentration of 0.3% by mass percentage, taking the supernatant and setting aside;

[0028] 4) Mix the chitosan solution with the supernatant of the konjac fine powder solution in a ratio of 1:1 by volume, stir conventionally, and prepare a coating preservative.

Embodiment 2

[0030] 1) The natural chitosan is subjected to 100kGy electron beam irradiation treatment to obtain degraded chitosan, for subsequent use;

[0031] 2) Anhydrous acetic acid is dissolved in distilled water to be prepared into an acetic acid solution with a volume concentration of 1mL / 100mL, and then the degraded chitosan is dissolved in the acetic acid solution to prepare a chitosan solution with a mass percentage concentration of 2%. ;

[0032] 3) Dissolving the konjac fine powder in distilled water, stirring conventionally, and preparing a konjac fine powder solution with a concentration of 0.5% by mass percentage, taking the supernatant and setting aside;

[0033] 4) Mix the chitosan solution with the supernatant of the konjac fine powder solution in a ratio of 1:1 by volume, stir conventionally, and prepare a coating preservative.

Embodiment 3

[0035] 1) The natural chitosan is subjected to 150kGy electron beam irradiation treatment to obtain degraded chitosan, for subsequent use;

[0036] 2) anhydrous acetic acid is dissolved in distilled water and is mixed with the acetic acid solution that volume concentration is 1mL / 100mL, then described degraded chitosan is dissolved in described acetic acid solution, is mixed with the chitosan solution that mass percent concentration is 3% ;

[0037] 3) Dissolving konjac fine powder in distilled water, conventionally stirring, and preparing a konjac fine powder solution with a concentration of 1.5% by mass percentage, taking the supernatant for subsequent use;

[0038]4) Mix the chitosan solution with the supernatant of the konjac fine powder solution in a ratio of 1:1 by volume, stir conventionally, and prepare a coating preservative.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com