High-concentration compound fertilizer and production method thereof

A production method and compound fertilizer technology, which are applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of large investment, high pollution and high energy consumption, and achieve the effects of less investment, reduced material moisture, and low moisture content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

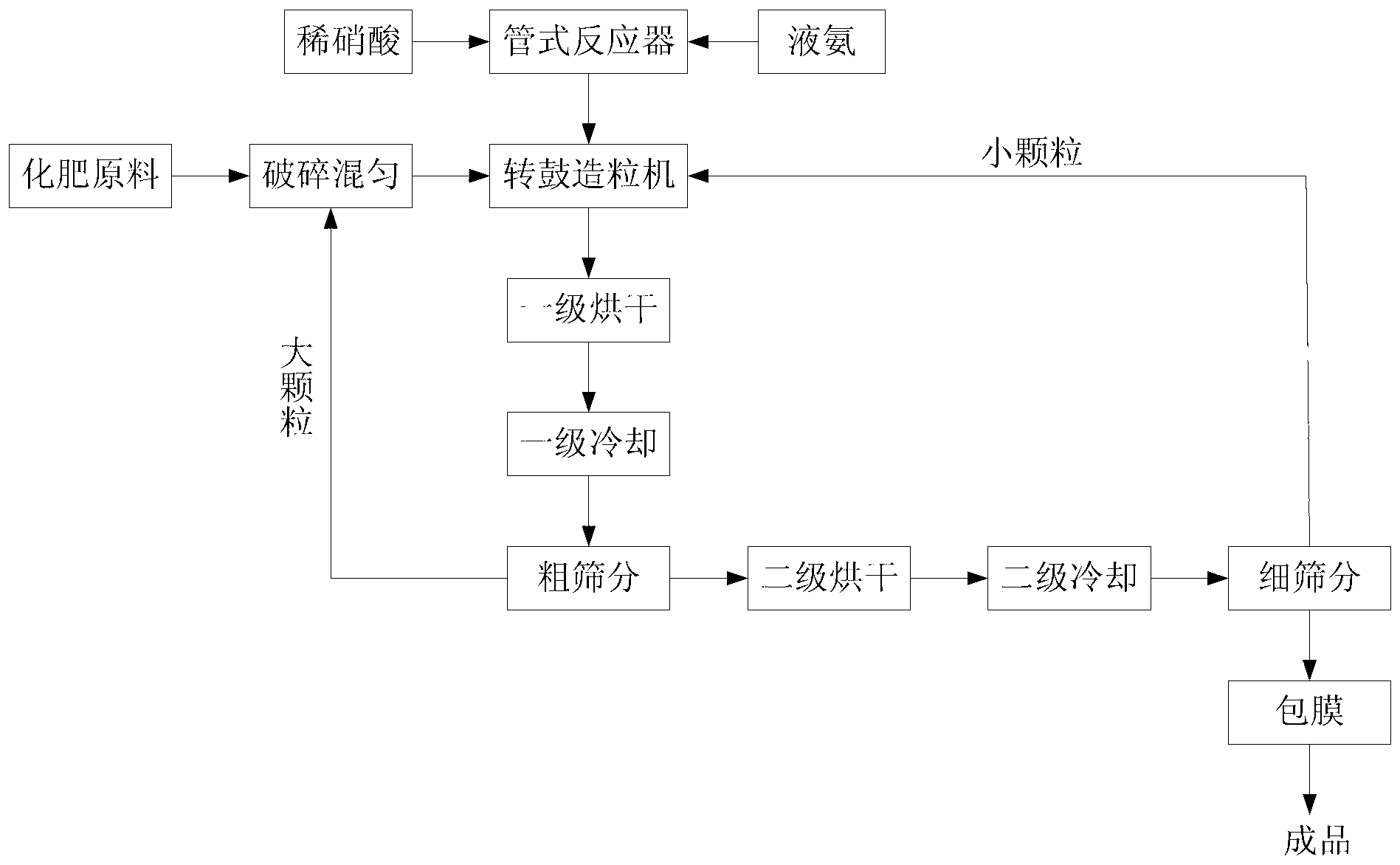

Method used

Image

Examples

Embodiment 1

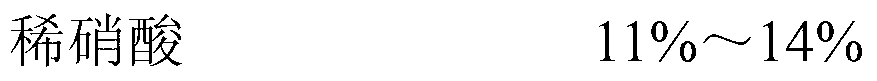

[0048] A high-concentration compound fertilizer, based on the total mass of all raw materials, the raw materials contain components with the following mass percentages:

[0049]

[0050] (1) Crushing and mixing of materials: Accurately weigh 180 kg of ammonium phosphate, 360 kg of ammonium chloride, 110 kg of nitrophos, and 199 kg of potassium chloride and put them into the crusher and mix them evenly, then mix them The uniform raw material is fed into the drum granulator.

[0051] (2) Amino acid reaction: 40 kg of liquid ammonia and 110 bus concentration of 50% dilute nitric acid are passed into the tubular reactor for acid reaction to generate ammonium nitrate.

[0052] (3) Drum granulation: Spray the ammonium nitrate produced by the above reaction in the drum granulator, use the chemical reaction heat of liquid ammonia and dilute nitric acid to granulate, and add an appropriate amount of steam to make the granulator in the granulator The granulation temperature is at 40...

Embodiment 2

[0056] A high-concentration compound fertilizer, based on the total mass of all raw materials, the raw materials contain components with the following mass percentages:

[0057]

[0058] (1) Crushing and mixing of materials: Accurately weigh 150 kg of ammonium phosphate, 400 kg of ammonium chloride, 107 kg of nitrophos, and 180 kg of potassium chloride and put them into the crusher and mix them evenly, then mix them The uniform raw material is fed into the drum granulator.

[0059] (2) Amino acid reaction: 20 kg of liquid ammonia and 140 m of dilute nitric acid with a concentration of 60% are passed into the tubular reactor for acid reaction to generate ammonium nitrate.

[0060] (3) Drum granulation: Spray the ammonium nitrate produced by the above reaction in the drum granulator, use the chemical reaction heat of liquid ammonia and dilute nitric acid to granulate, and add an appropriate amount of steam to make the granulator in the granulator The granulation temperature ...

Embodiment 3

[0064] A high-concentration compound fertilizer, based on the total mass of all raw materials, the raw materials contain components with the following mass percentages:

[0065]

[0066] (1) Crushing and mixing of materials: Accurately weigh 175 kg of ammonium phosphate, 383 kg of ammonium chloride, 90 kg of nitrophos, and 200 kg of potassium chloride and put them into the crusher and mix them evenly, then mix them The uniform raw material is fed into the drum granulator.

[0067] (2) Amino acid reaction: 30 kg of liquid ammonia and 120 m of dilute nitric acid with a concentration of 55% are passed into the tubular reactor for acid reaction to generate ammonium nitrate.

[0068] (3) Drum granulation: Spray the ammonium nitrate produced by the above reaction in the drum granulator, use the chemical reaction heat of liquid ammonia and dilute nitric acid to granulate, and add an appropriate amount of steam to make the granulator in the granulator The granulation temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com