Addend preparation method and process for wet oxidation-desulfurizing catalyst

A desulfurization catalyst and preparation method technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve product reaction kinetic defects, preparation process can not meet chemical The basic conditions of the reaction, the cost of unit consumption cannot be reduced, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

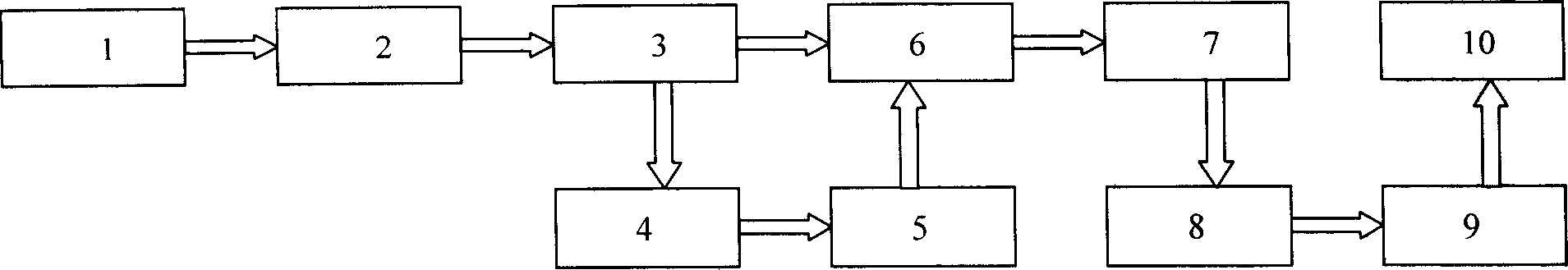

[0006] The present invention is realized in such a way that phthalic anhydride and oleum are subjected to continuous dynamic sulfonation reaction at normal pressure and conditional temperature, and then neutralized with alkali solution to remove free acid, then neutralized with ammonia water, and subjected to constant temperature Concentrate and filter to obtain the ammonium sulfonate product; then mix the sulfonated component with the condensation component phthalic dianhydride, carbonamide, cobalt chloride, ammonium chloride, ammonium molybdate, and ammonium nitrate through continuous Stirring and dry mixing at elevated temperature, in the presence of compound components such as organic solvent cyclobutane and catalyst titanium tetrachloride, carry out liquefaction mixing, washing, neutralization and removal of impurities, and then the mixture is divided into equal parts and subjected to a second constant temperature Static condensation reaction to generate foamed cobalt phth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com