Activating process for nonmetal basal body chemical plating

An electroless plating, non-metallic technology, applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of tin ion interference, complicated operation, unstable activation solution, etc., and achieve convenient operation and practicability wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1). Preparation of activation solution: 0.08gPdCl 2 Add to 10ml of aqueous solution, shake well, adjust PdCl with 40ml of 1M NaOH solution 2 The pH value of the solution was brought to 10, and ultrasonically oscillated for 2 hours. During this process, PdCl 2 After hydrolysis, it reacts with NaOH to form a colloid, and finally obtains a stable colloid with a pH value of 6, in which the palladium content is 0.005 mol / L.

[0024](2). Activation: Immerse the washed and dried porous ceramic substrate in the above-mentioned colloid, take it out when the substrate turns orange and the color distribution is relatively uniform, and the solution blown to the surface of the carrier with a hair dryer no longer flows, and put it in hydrogen Under atmosphere, reduce at 50°C for 3h until the orange matrix turns black.

[0025] (3). Use electroless plating method to plate palladium film. The composition of the palladium plating solution is: 5g / L PdCl 2 , 500ml / L concentrated ammo...

Embodiment 2

[0028] (1). The preparation of the activation solution is the same as that in Example 1 (1). But the palladium source was changed to 0.5g of Pd(NO 3 ) 2 , the lye is 10ml of 2M KOH solution, and finally a stable colloid with a pH value of 5 is obtained, wherein the palladium content is 0.05mol / L.

[0029] (2).Activation: Immerse the washed and dried porous glass substrate in Pd(OH) 2 Take out the suspension when the surface turns orange and the color distribution is relatively uniform, and dry at 120°C. After taking it out and cooling to room temperature, put it into 0.1M N at a temperature of 70°C 2 h 4 Restore in the solution for 5 minutes, take it out, and wash away the substances with poor surface adhesion with water.

[0030] (3). The electroless plating method prepares the palladium film with embodiment 1 (3).

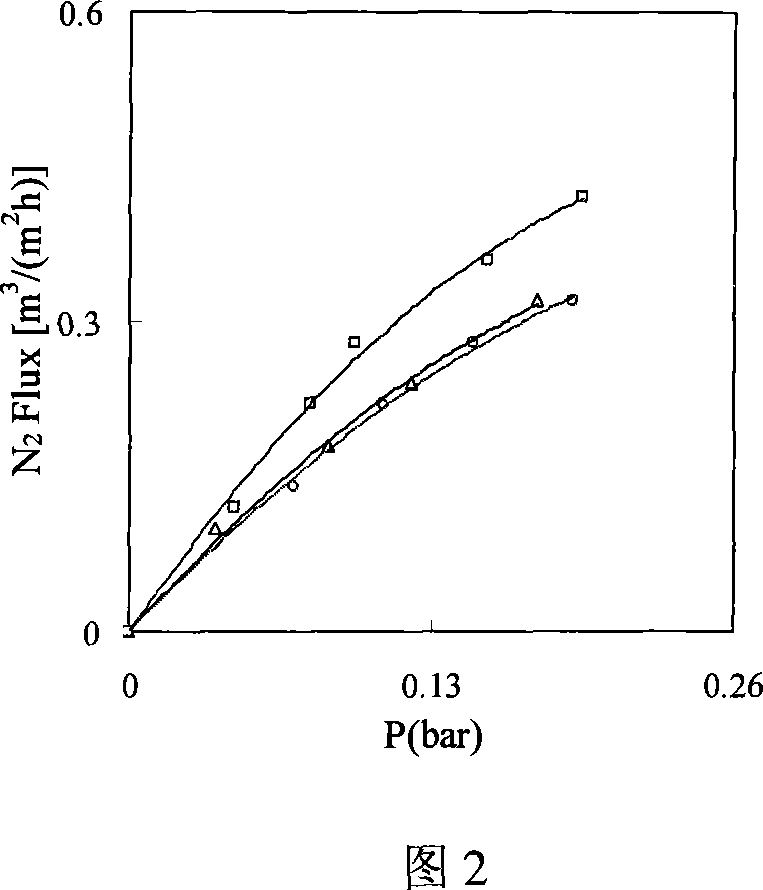

[0031] The palladium film prepared after the activation of this method has fewer defects than that of the traditional method (as shown by the ○ curve in FI...

Embodiment 3

[0033] (1). After corroding the dense glass carrier with hydrofluoric acid, it is cleaned and dried.

[0034] (2). The preparation of activation solution, the activation of matrix, and the method for electroless palladium plating are the same as embodiment 1 (1), (2). However, the palladium source was changed to 0.1g of PdCl during activation 2 , the lye is 40ml of 1M NaOH solution, and the palladium content in the colloid is 0.007mol / L. with H 2 During reduction, the temperature is 200°C and the time is 0.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com