Method for full constituent utilizing resources of wastes of plastic containing chlorine in fluid bed

A fluidized bed and waste technology, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of waste of chlorine resources, low price, environmental pollution, etc., and achieve the effect of compact equipment and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

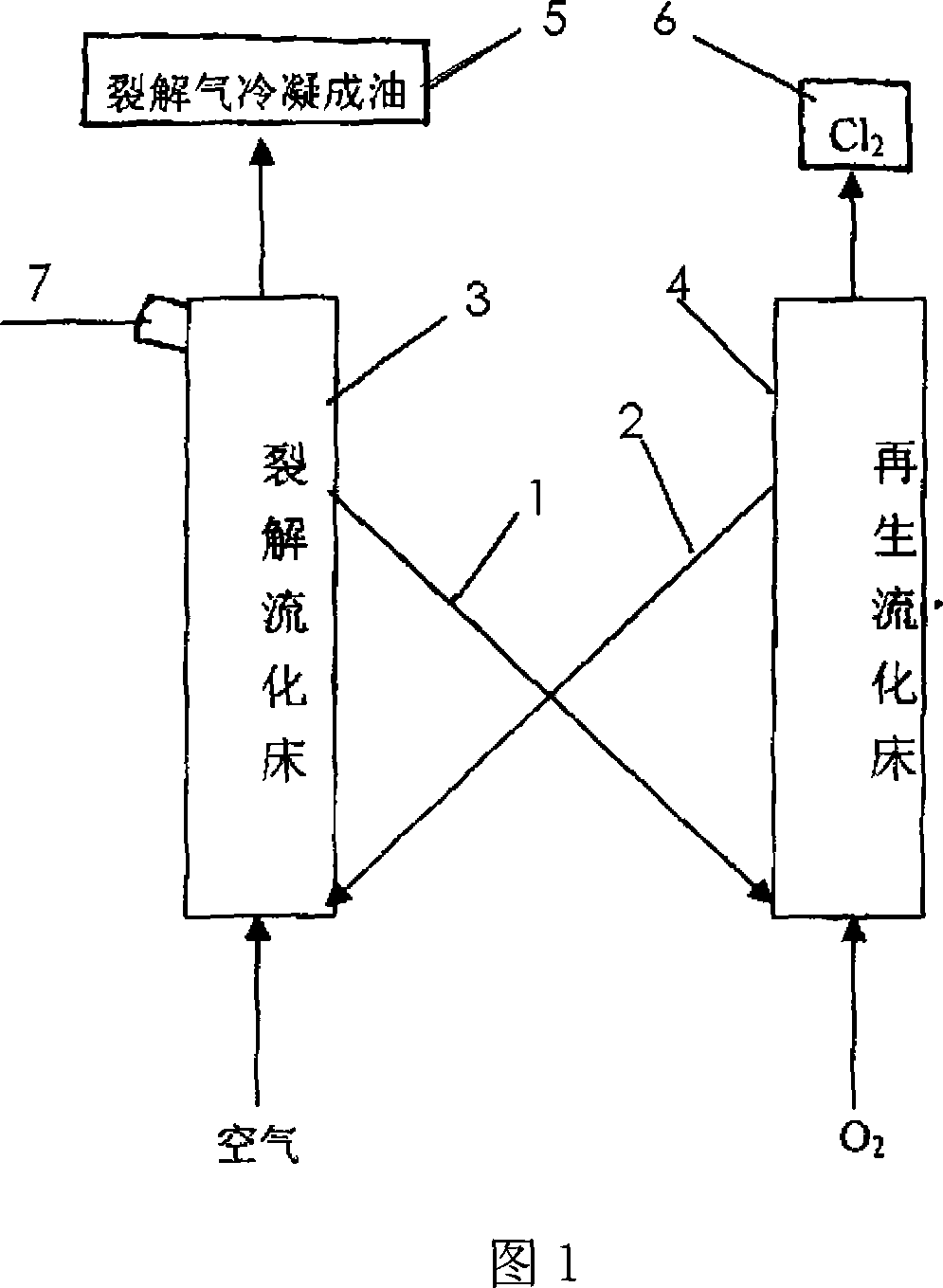

[0027] The reaction was carried out in a dual fluidized bed coupling system as shown in FIG. 1 . Sand with a particle size of 0.2mm is used as the heat carrier of the fluidized bed, and the real density of the sand is 2500kg / m 3 , bulk density is 1300kg / m 3 . CuO is a dechlorination agent, sand: CuO=5:1 (weight ratio). Add plastic waste solid particles with a screw feeder, the particle size is 2mm. The cracking fluidized bed maintains a temperature of 240°C, the regeneration fluidized bed maintains a temperature of 360°C, and the cracking fluidized bed and the regeneration fluidized bed are kept connected. After 3 hours, the connection between the two beds was cut off, and the temperature of the cracking fluidized bed was raised to 360° C. to crack other components in the plastic. Experimental results: HCl removal rate is 67.2%, HCl is converted to Cl 2 The yield was 81.5%, and the oily rate was 67%.

Embodiment 2

[0029]The reaction was carried out in a dual fluidized bed coupling system as shown in FIG. 1 . Sand with a particle size of 0.2 mm is used as the heat carrier of the fluidized bed, CuO is used as the dechlorination agent, and sand: CuO=4.5:1 (weight ratio). Add plastic waste solid particles with a screw feeder, the particle size is 2mm. The cracking fluidized bed temperature is maintained at 280°C, and the regeneration fluidized bed temperature is 400°C. The experimental results are: HCl removal rate is 98.2%, HCl is converted into Cl 2 The yield was 98.5%, and the oil yield was 79%.

Embodiment 3

[0031] The reaction was carried out in a dual fluidized bed coupling system as shown in FIG. 1 . Sand with a particle size of 0.2 mm is used as the heat carrier of the fluidized bed, CuO is used as the dechlorination agent, and sand:CuO=5.5:1 (weight ratio). Add plastic waste solid particles with a screw feeder, the particle size is 2mm. The cracking fluidized bed temperature is maintained at 320°C, and the regeneration fluidized bed temperature is 400°C. Experimental results: HCl removal rate is 99.2%, HCl is converted to Cl 2 The yield is 93.5%, the selectivity is 99%, and the oily rate is 76%.

[0032] Chlorine and hydrogen chloride are important forms of chlorine. Chlorine gas is the primary raw material for the production of various chlorine-containing products, including the production of PVC, polyurethane epoxy, silicone, synthetic rubber, HCFCs, TiO 2 paint etc. Chlorine for industrial use is mainly obtained by electrolysis of salt water and caustic soda. At pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com