Agent for soil expansion and increment prepared from household slag and production method

A technology of expanding storage capacity and slag, which is applied in the fields of application, organic fertilizer, nitrogen fertilizer, etc., can solve problems such as not seen, achieve good social benefits, improve water use efficiency, and improve comprehensive utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The soil expansion and storage compatibilizer prepared by the domestic slag of the present embodiment is composed of the following raw materials and their weight percentages: domestic slag powder: 40%, potassium dihydrogen phosphate: 10%, diammonium phosphate: 20%, rapeseed residue: 10% %, urea: 1%, high-fat film: 1%, mixed crop straw powder: 18%.

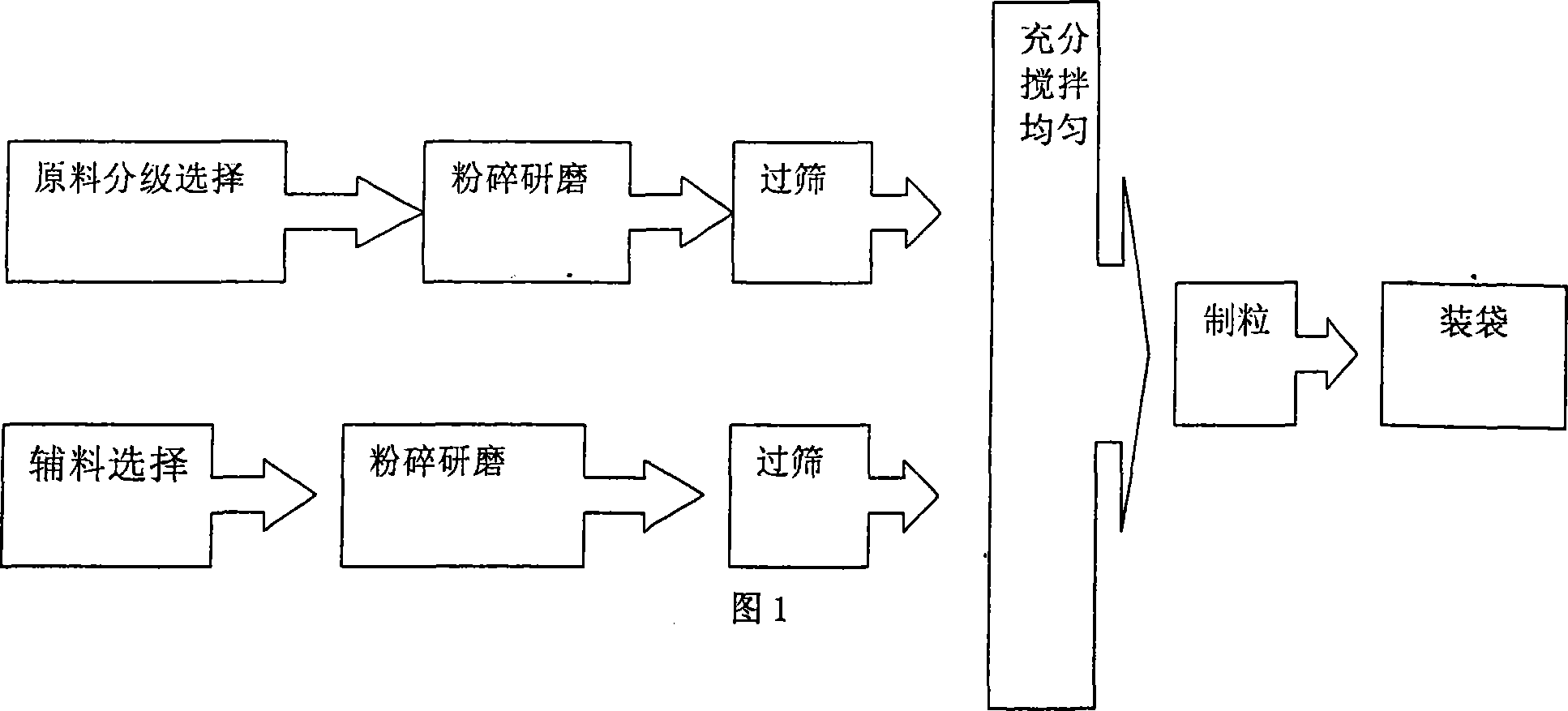

[0031] The process for making the above-mentioned soil expansion and storage compatibilizer specifically includes the following steps (Fig. 1):

[0032] (1) Eliminate domestic slag for other purposes. Classify domestic slag, then pulverize and grind it to less than 1mm (20 mesh), and sieve it for later use after grinding.

[0033] (2) Air-dry the auxiliary materials potassium dihydrogen phosphate, diammonium phosphate, rapeseed residue, and mixed crop straw, pulverize, grind, and pass through a 1 mm sieve (20 mesh) for later use.

[0034] (3) Mix 40% of domestic slag powder, 10% of potassium dihydrogen phosphate, 20% of diam...

Embodiment 2

[0037] The difference between this example and Example 1 is that the ingredients of the raw materials are different, and the preparation method is the same as that of Example 1.

[0038] Raw materials and their weight percentages are: domestic slag powder: 35%, potassium dihydrogen phosphate: 15%, diammonium phosphate: 15%, rapeseed residue: 15%, urea: 2%, high-fat film: 1.5%, and crop mix Straw Powder: 16.5%.

Embodiment 3

[0040] The difference between this example and Example 1 is that the ingredients of the raw materials are different, and the preparation method is the same as that of Example 1.

[0041] Raw materials and their weight percentages are: domestic slag powder: 45%, potassium dihydrogen phosphate: 18%, diammonium phosphate: 15%, rapeseed residue: 10%, urea: 1%, high-fat film: 1%, and crop mix Straw Powder: 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com