Recycling method for using dregs of incinerator for municipal garbage

A technology for incinerating slag and municipal waste, applied in chemical instruments and methods, separating solids from solids by air flow, magnetic separation, etc. The problem of high energy consumption, to achieve the effect of increasing economic added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] Example 1: Example 1 of resource utilization method of municipal waste incineration slag

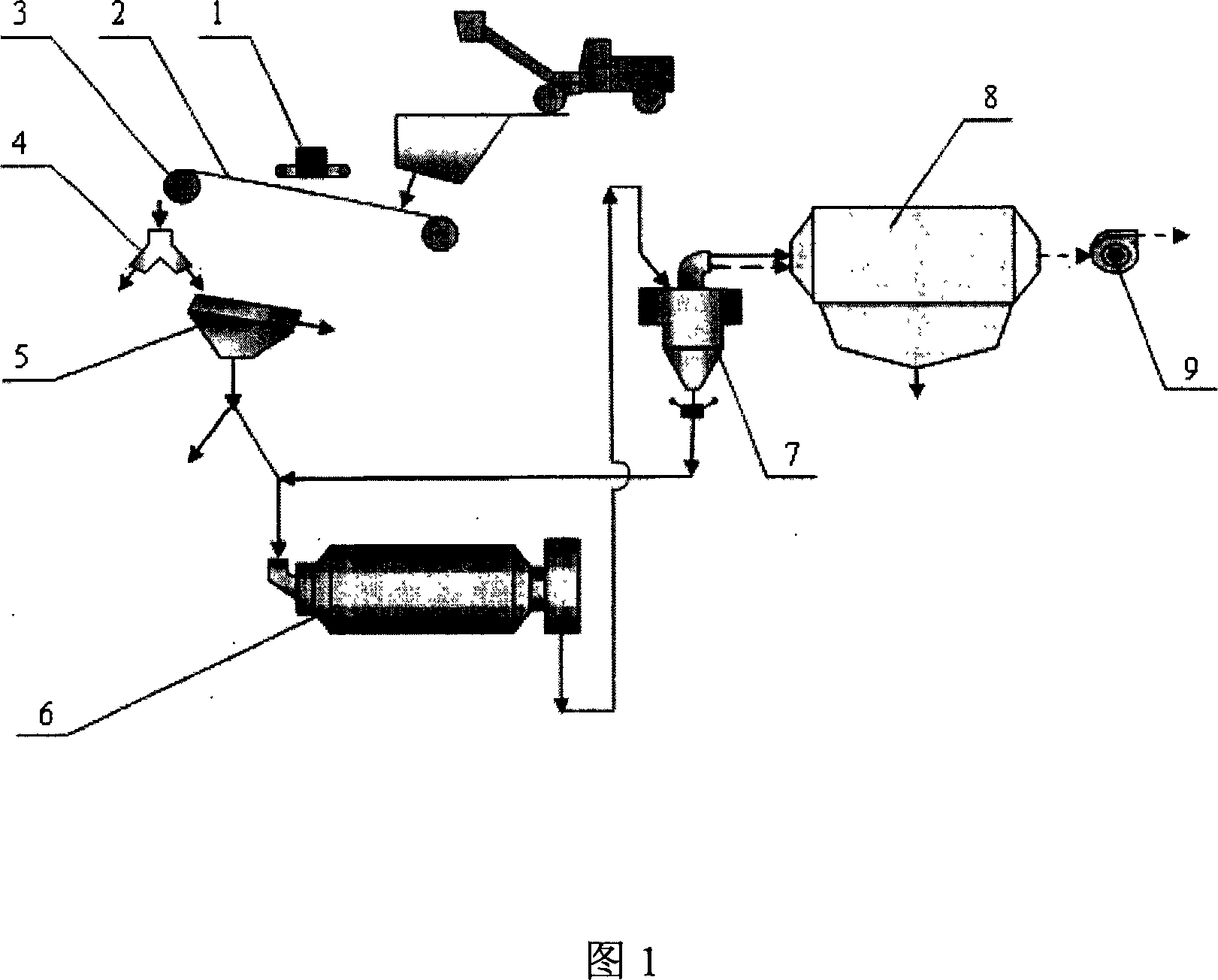

[0033] See attached drawing 1, the specific steps are as follows:

[0034] ① First remove the scrap iron from the slag of municipal waste incineration: the slag is transported from the storage warehouse to the fine powder processing workshop through the belt conveyor 2. During the transportation process, the slag on the belt conveyor is magnetically removed by the belt electromagnetic iron remover 1 , focusing on removing large pieces of scrap iron in the slag; the head roller of the belt conveyor is replaced by a slag roller permanent magnetic iron remover 3 The second magnetic iron removal is performed on the slag that is about to leave the belt conveyor, and most of the iron filings can be removed . Then carry out screening with vibrating screen 5 again, by above-mentioned three procedures, scrap iron removal rate can reach more than 98% in the incineration slag, and bulk mate...

example 2

[0041] Example 2: Example 2 of resource utilization method of municipal waste incineration slag

[0042] See attached drawing 1, the specific steps are as follows:

[0043] ① First remove the scrap iron from the municipal waste incineration slag: the slag is transported from the storage warehouse to the fine powder processing workshop through the belt conveyor 2. During the transportation process, the belt electromagnetic iron remover 1 is used to magnetically remove the iron from the slag on the belt conveyor. Focus on removing large pieces of scrap iron in the slag; the head roller of the belt conveyor is replaced by a slag roller permanent magnetic iron remover 3. The second magnetic iron removal is performed on the slag that is about to leave the belt conveyor, and most of the iron filings can be removed. Then carry out screening with vibrating screen 5 again, by above-mentioned three procedures, scrap iron removal rate can reach more than 98% in the incineration slag, and...

example 3

[0050] Example 3: Example 3 of the resource utilization method of municipal waste incineration slag

[0051] See attached drawing 1, the specific steps are as follows:

[0052] ① First remove the scrap iron from the municipal waste incineration slag: the slag is transported from the storage warehouse to the fine powder processing workshop through the belt conveyor 2. During the transportation process, the belt electromagnetic iron remover 1 is used to magnetically remove the iron from the slag on the belt conveyor. Focus on removing large pieces of scrap iron in the slag; the head roller of the belt conveyor is replaced by a slag roller permanent magnetic iron remover 3. The second magnetic iron removal is performed on the slag that is about to leave the belt conveyor, and most of the iron filings can be removed. Then carry out screening with vibrating screen 5 again, by above-mentioned three procedures, scrap iron removal rate can reach more than 98% in the incineration slag,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com