Electrochemical sensor and its prepn process and use

A sensor and electrochemical technology, applied in the field of DNA electrochemical sensor preparation, can solve the problems of insensitive detection of low-copy gene sequences, time-consuming and labor-intensive chromosome analysis, low sensitivity, etc., so as to accelerate the electron transfer rate and increase the amount of covalent fixation. , the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

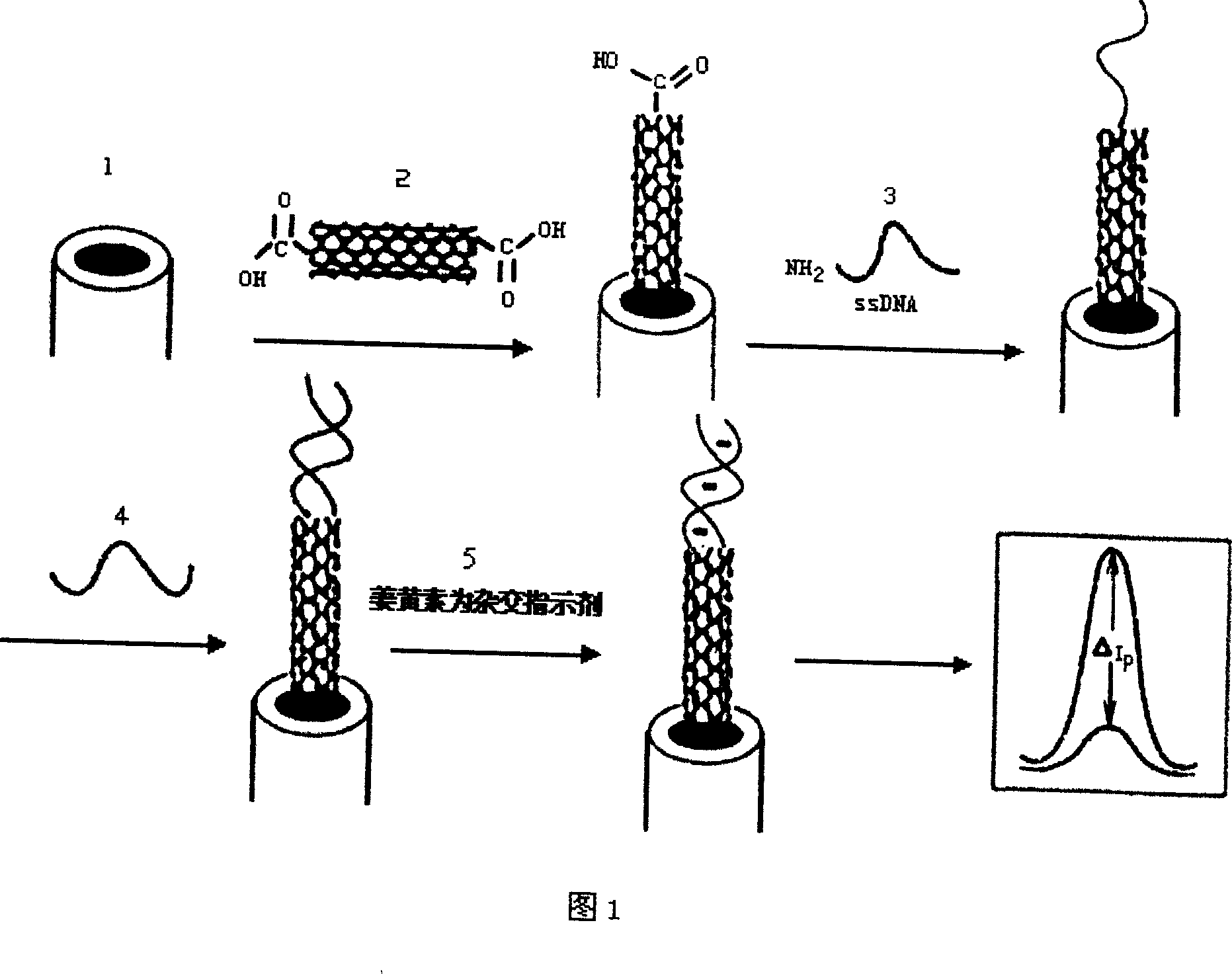

[0027] The preparation method of above-mentioned sensor

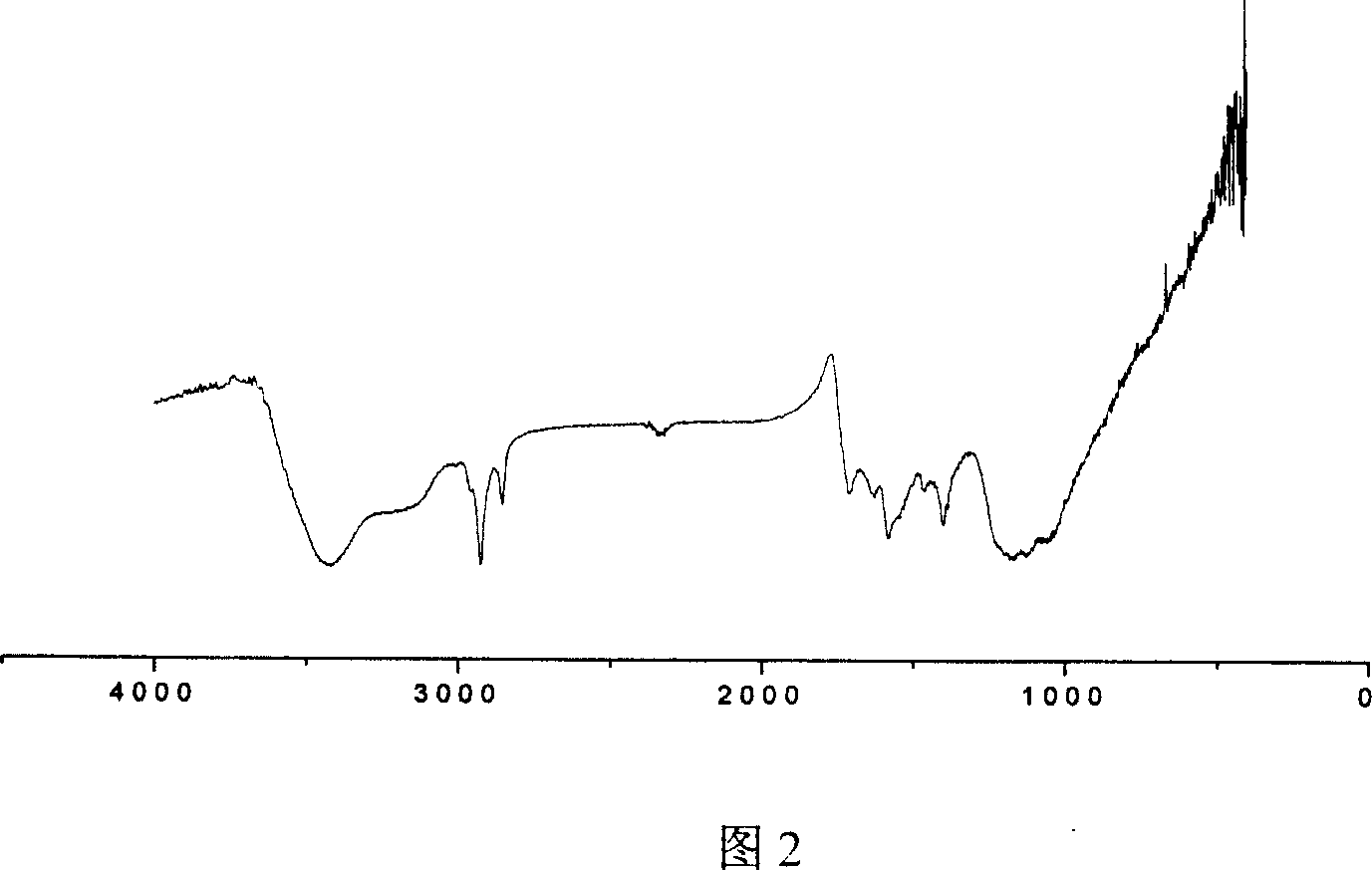

[0028] 1) Preparation of carboxylated multi-walled carbon nanotubes: After soaking the carbon nanotubes in HF acid to remove catalysts and other impurities, reflux in mixed acid (concentrated sulfuric acid: concentrated nitric acid) at 120°C to 130°C for 1 to 2 hours, Stand overnight, discard the supernatant, wash with water until neutral, freeze-dry, and set aside. After the carbon nanotubes were soaked in HF acid to remove catalysts and other impurities, they were boiled with mixed acid for a certain period of time, and their infrared spectra were measured. The results are shown in Figure 2. After boiling with the mixed acid. The carboxyl peak (v -cooH 1720cm) is gradually enhanced, indicating that the oxidation of mixed acids can indeed produce carboxyl groups.

[0029] 2) Preparation of multi-walled carbon nanotubes (MWNTS) modified glassy carbon electrodes: 1-100 mg of carboxylated multi-walled carbon nanotubes (...

Embodiment 1

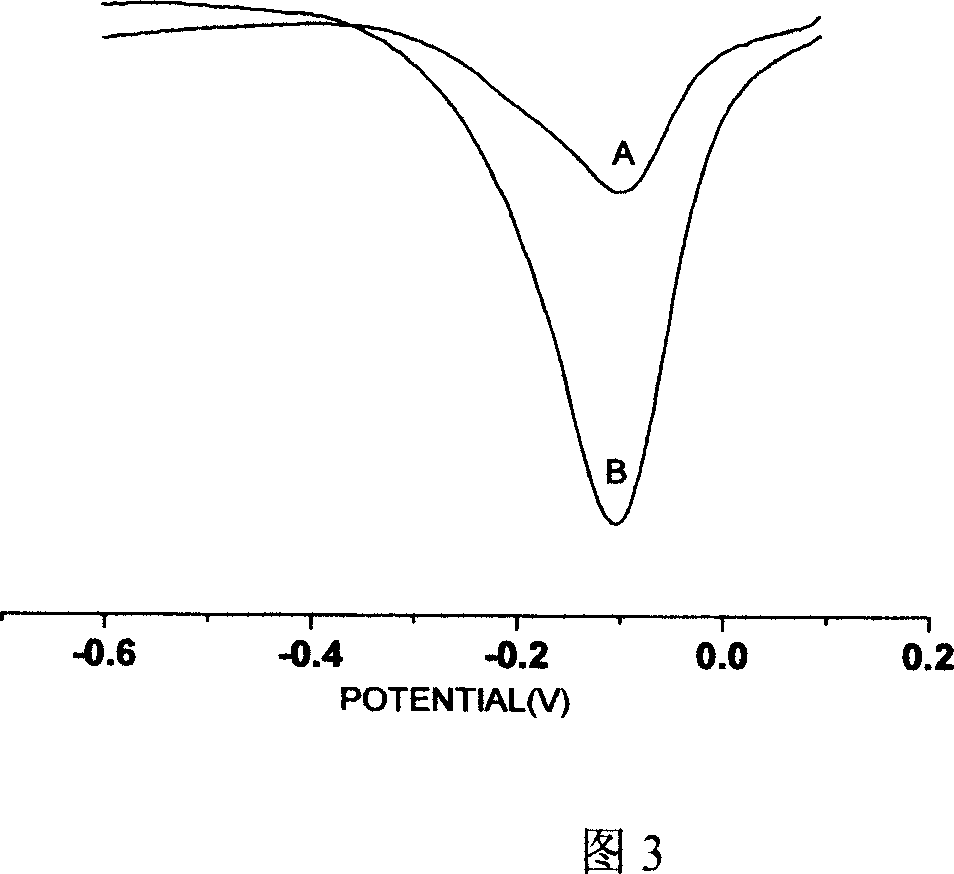

[0035] Embodiment 1: An electrochemical sensor includes a glassy carbon electrode, and the surface of the glassy carbon electrode is coated with a sensitive film. The sensitive membrane consists of 0.01mg carboxylated multi-walled carbon nanotubes and b3-a2 gene (NH 2 -DNA) composition, the following NH 2 -The DNAs are all b3-a2 type genes with amino groups modified at the ends.

[0036] The preparation method of the above electrochemical sensor is to add 10 mg of carbon nanotubes into 10 milliliters of DMF, ultrasonically disperse until a uniform, light black carbon nanotube dispersion is obtained, and apply 10 microliters of carbon nanotube dispersion to the surface of the glassy carbon electrode , baked under infrared light to evaporate the solvent, and the MWNTS-COOH modified electrode was fully washed in ethanol and secondary water to remove excess carbon nanotubes. Then soak it in 30mmol / L acetic acid buffer solution containing 10mmol / L EDC to stir the reaction, wash i...

example 2

[0037] Example 2: An electrochemical sensor, including a glassy carbon electrode, the surface of the glassy carbon electrode is coated with a sensitive film. The sensitive film is composed of 0.1 mg carboxylated multi-walled carbon nanotubes and b3-a2 gene with terminal modified amino groups.

[0038] The preparation method of the above electrochemical sensor is to add 50 mg of carbon nanotubes into 10 ml of DMF, disperse ultrasonically until a uniform, light black carbon nanotube dispersion is obtained, and apply 20 microliters of the carbon nanotube dispersion to the surface of the glassy carbon electrode , baked under infrared light to evaporate the solvent, and the MWNTS-COOH modified electrode was fully washed in ethanol and secondary water to remove excess carbon nanotubes. Then soak it in 30mmol / L acetic acid buffer solution containing 10mmol / L EDC to stir the reaction, wash it with acetic acid buffer solution and place it in the solution containing 3.5μmol / L NH 2 -in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com