Silk-screen printing device

A technology of screen printing device and printed substrate, which is applied in the direction of screen printing machine, printing machine, printing machine, etc., can solve the problems that cannot be expected, and achieve the effect of improving yield rate, stabilizing and reducing unqualified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

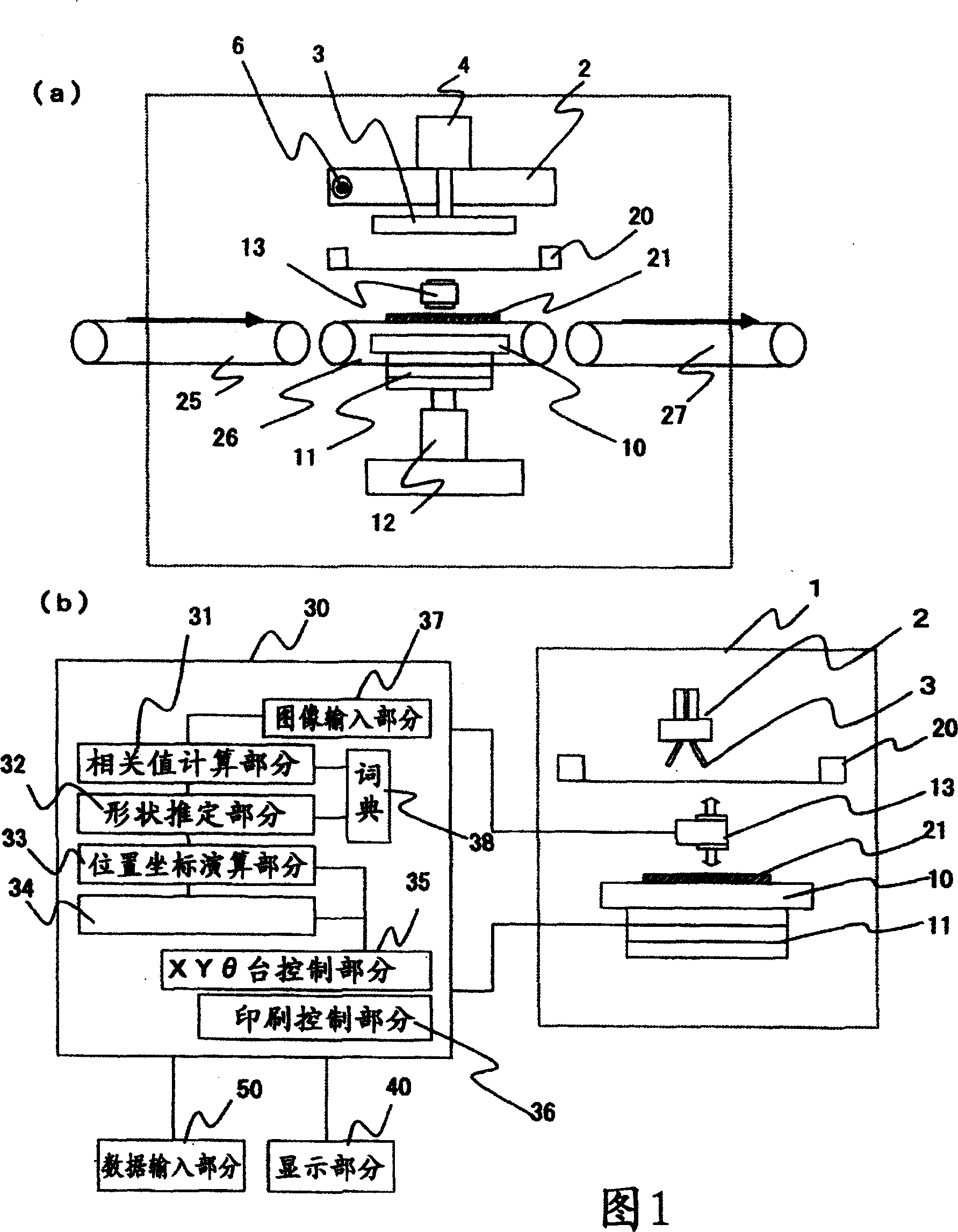

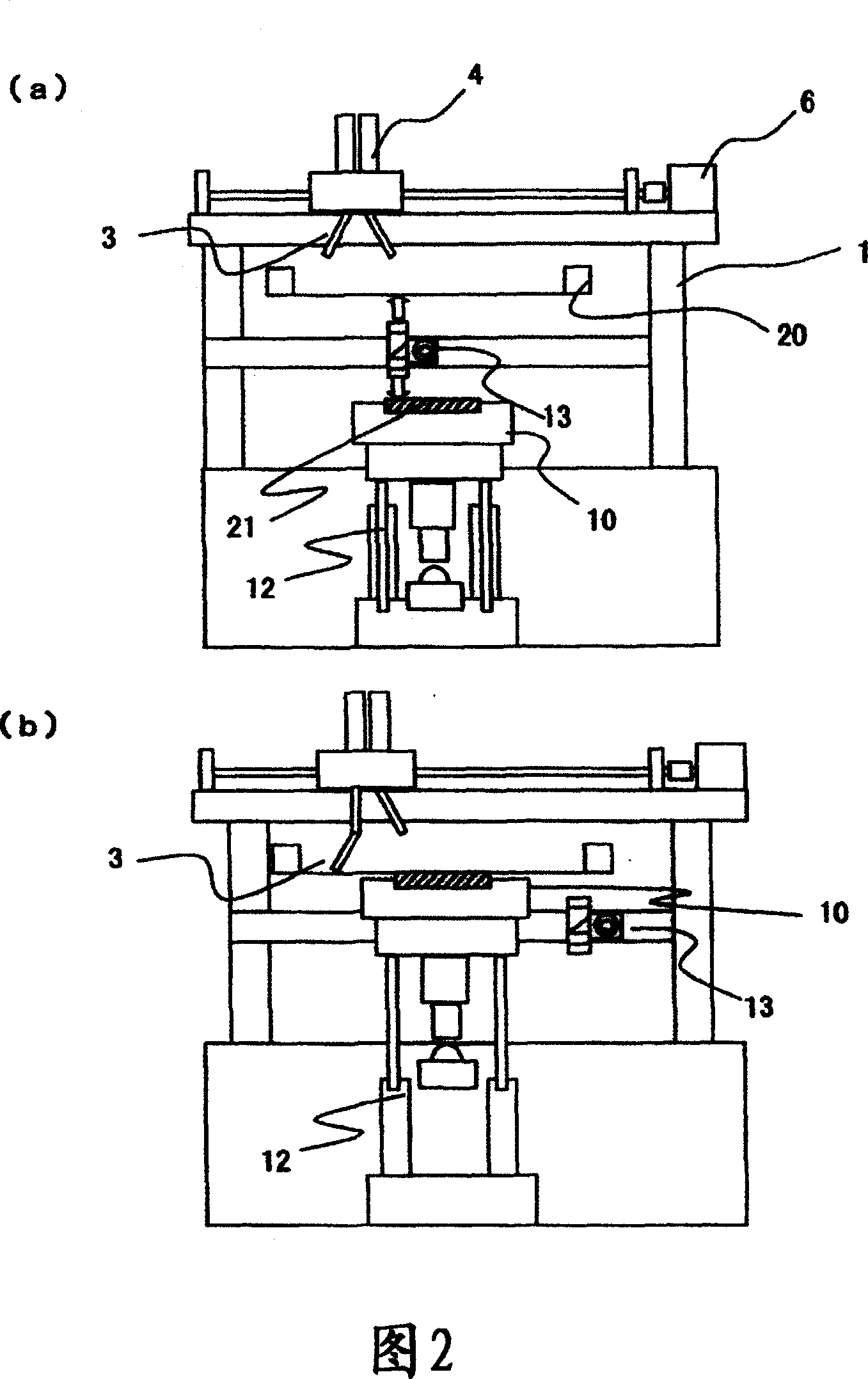

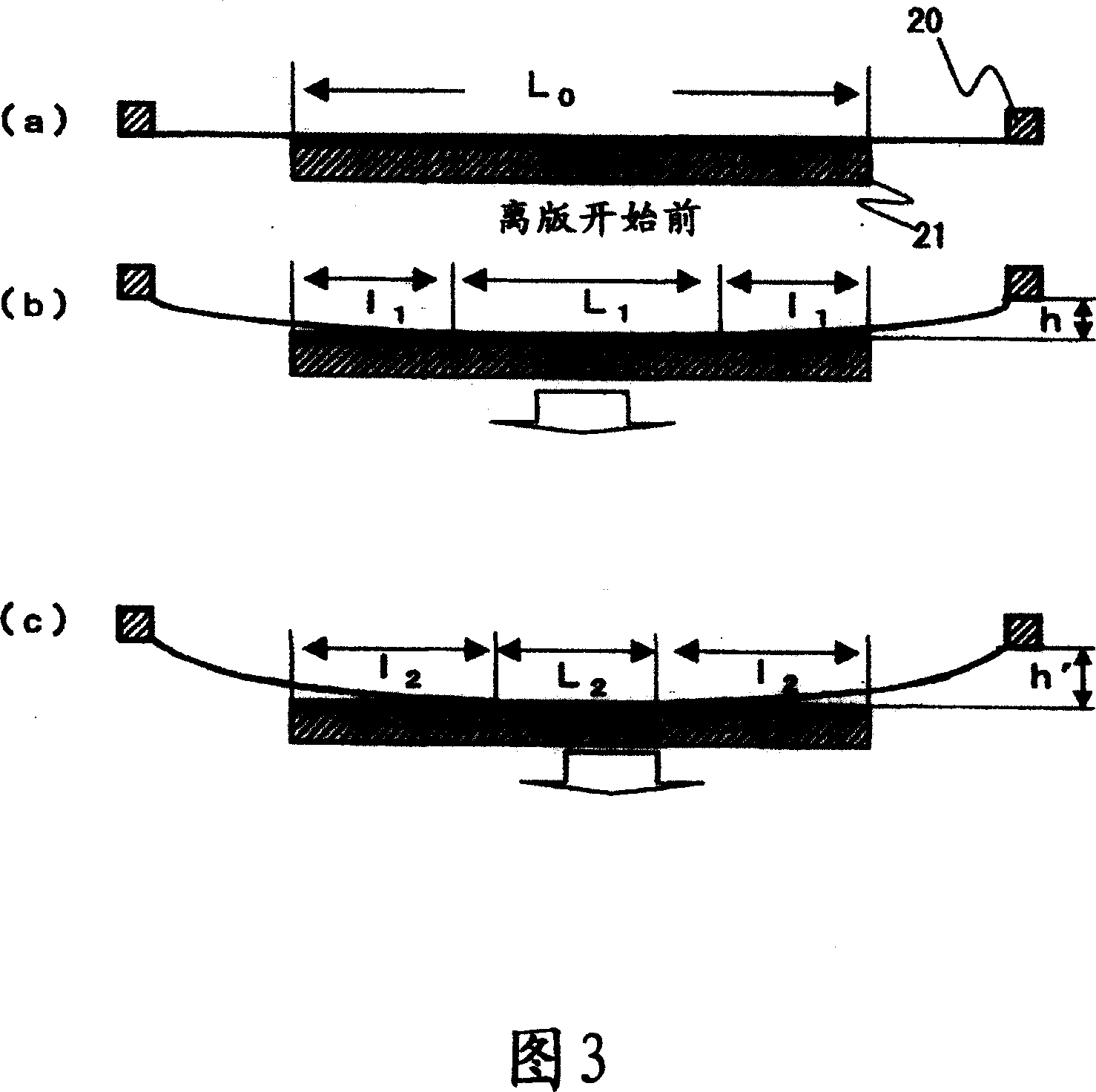

[0025] The structure of the screen printing apparatus of this invention is demonstrated using FIG.1, FIG.2. Figure 1(a) shows the structure and system structure diagram seen from the front of the screen printing device. And the control system of (a) is shown in FIG. 1(b). The structure of the screen printing apparatus viewed from the side is shown in FIG. 2( a ). And in FIG. 2( b ), the screen printing device is viewed from the side and the printing state is shown.

[0026] A frame support is provided on the main body frame, and a mask 20 in which a screen having a printed pattern as an opening portion is developed is provided on the frame support. A squeegee head 2 is disposed above the mask 20 , and a squeegee 3 is attached to the squeegee head 2 . The squeegee head 2 is movable in the horizontal direction by a squeegee moving mechanism 6 composed of a ball screw and a motor, and the squeegee 3 is movable in an up and down direction by a squeegee elevating mechanism 4 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com