Assembling method for double curved surface metal curtain wall

A metal curtain wall and assembly method technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of neat surface block joints and smooth surface lines, affecting the appearance of metal curtain walls, etc., to improve the effect, improve design efficiency, connect neat seam effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

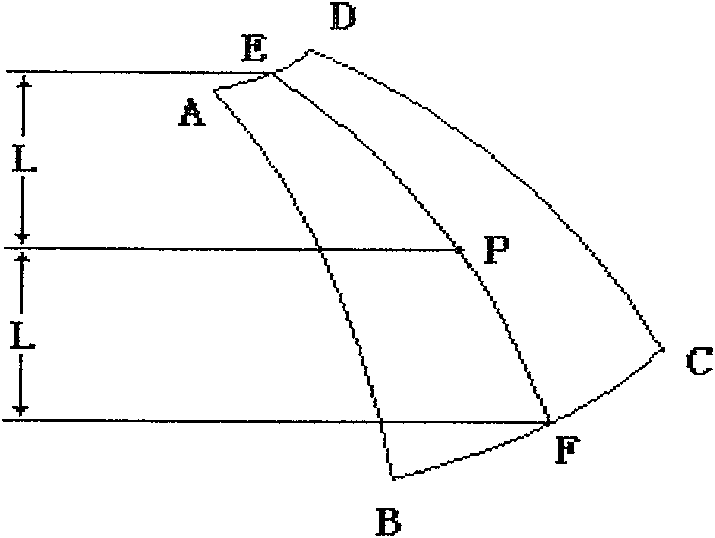

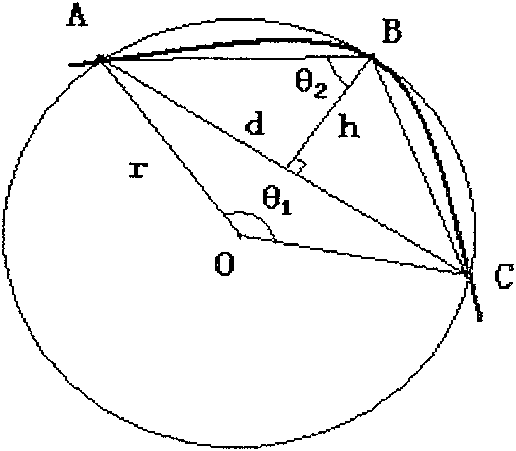

[0024] The method for assembling the hyperboloid metal curtain wall of the present invention is characterized in that the equilateral center distance method is adopted, and the size of the plane block corresponding to the curved surface block is determined according to each divided small curved surface block, which ensures that the plane block after blanking and punching is made into a corresponding When the curved surface block is used, it is very consistent with the designed curved surface block, so as to ensure that the joints between the curved surface blocks of the assembled metal curtain wall are neat and the curved surface lines are smooth.

[0025] The present invention is described below with an embodiment of an ellipsoidal metal curtain wall.

[0026] Step 1: Various software can be used to design the three-dimensional shape of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com