H-shaped steel welding device and welding process thereof

A welding device and welding process technology, applied in the field of H-beam welding device and its welding process, can solve the problems of slow speed, poor quality, low efficiency, etc., and achieve the effects of high welding, high automation and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

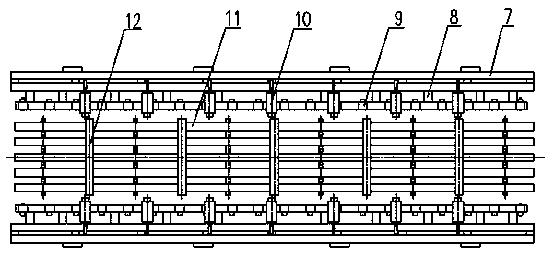

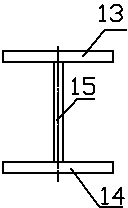

[0020] Combined with the accompanying drawings, the H-shaped steel is welded by the flange plate and the web, and the orthographic projection of the web is a rectangle, so this kind of H-shaped steel is equal-section H-shaped steel 18, and the orthographic projection of the web is trapezoidal, then this kind of H-shaped steel It is H-shaped steel with variable cross-section.

[0021] In order to realize the automatic input and welding of H-shaped steel blank materials, this welding equipment is composed of an input part, a welding part and an output part. In the input part, the flange boards to be used are stored in the flange board box 7, the flange boards are laid flat and stacked together one by one, and the lifting platform 8 can lift the flange board box 7. During work, the flange plate to be used is placed in the flange plate box 7, and is raised to a high position by the lifting platform 8, and then the uppermost flange plate slides to a low position under the action of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com